Wuhan Sintec Optronics Co., Ltd, |

|

Verified Suppliers

|

|

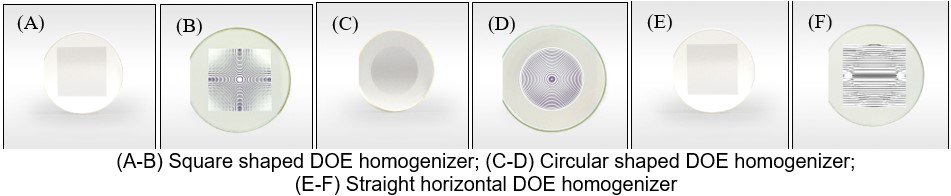

1.1 DOE Homogenizers

DOE homogenizer is a flat optical element designed based on the principle of diffraction optics, consisting of liquid crystal polymer (LCP) thin films and two N-BK7 window sheets. According to the known incident light parameters, lens focal length and expected outgoing light parameters, the design phase is calculated by point-to-point mapping. Finally, the designed geometric phase distribution is introduced into LCP film to shape and homogenize the Gaussian (TEM00, M2<1.3) incident light. The DOE homogenizer can achieve non collimated homogenization effects of any geometric shape such as square, circular, and linear for single mode lasers. Because of its advantages such as high uniformity, high transmittance, high damage threshold, and sharp boundary, it has great application prospects in laser medical beauty, laser processing, surface treatment and other scenarios, such as laser welding, laser marking, laser cutting, skin beauty, and laser treatment. It can bring higher energy utilization, better machining quality, higher machining accuracy, and more flexible and controllable machining scale adjustment. In addition to standard products, we also provide flexible customization of parameter specifications. If you need UV/high-power homogenization DOE, please contact us.

Product features

Standard product model

| Product model | Homogenization type | Working wavelength nm | Incident spot diameter mm | Effective lens focal length mm | Exit spot size μm |

| SLB-DOE25-532-6-FTS50 | Square flat roof | 532 | 6 | 100 | 50x50 |

| SLB-DOE25-532-6-FTS200 | Square flat roof | 532 | 6 | 100 | 200x200 |

| SLB-DOE25-532-7-FTS30 | Square flat roof | 532 | 7 | 100 | 30.3x30.3 |

| SLB-DOE25-532-7-FTS76 | Square flat roof | 532 | 7 | 100 | 75.76x75.76 |

| SLB-DOE25-1064-6-FTS80 | Square flat roof | 1064 | 6 | 100 | 80x80 |

| SLB-DOE25-1064-6-FTS200 | Square flat roof | 1064 | 6 | 100 | 200x200 |

| SLB-DOE25-1064-7-FTS30 | Square flat roof | 1064 | 7 | 100 | 30.3x30.3 |

| SLB-DOE25-1064-7-FTS76 | Square flat roof | 1064 | 7 | 100 | 75.76x75.76 |

| SLB-DOE25-532-6-FTC50 | Circular flat roof | 532 | 6 | 100 | Ø 50 |

| SLB-DOE25-532-6-FTC200 | Circular flat roof | 532 | 6 | 100 | Ø 200 |

| SLB-DOE25-1064-6-FTC80 | Circular flat roof | 1064 | 6 | 100 | Ø 80 |

| SLB-DOE25-1064-6-FTC200 | Circular flat roof | 1064 | 6 | 100 | Ø 200 |

| SLB-DOE25-532-6-FTL250 | Linear flat roof | 532 | 6 | 100 | 250 |

| SLB-DOE25-532-6-FTL1000 | Linear flat roof | 532 | 6 | 100 | 1000 |

| SLB-DOE25-1064-6-FTL250 | Linear flat roof | 1064 | 6 | 100 | 250 |

| SLB-DOE25-1064-6-FTL1000 | Linear flat roof | 1064 | 6 | 100 | 1000 |

Working parameter

| Product type | Standard products | Customization |

| Working wavelength | 532 nm, 1064 nm | 400-1700 nm |

| Component size and installation method | Ø 25.4x3.2mm, single side trimming, compatible with 1-inch optical component mounting bracket | |

| Incident beam quality | TEM00, M ²< 1.3 | |

| Polarization state of incident beam | Uniform polarization state | |

| Incident beam size | Ø 6 mm, Ø 7 mm | Suggest less than half of the optical aperture |

| Optical aperture | 15×15 mm, Ø 15 mm | |

| Shape of outgoing beam | Square, circular, linear | Any geometric shape |

| Exit spot size | >1.5 DL (diffraction limit), adjustable with matching focusing lens | |

| Non-uniform exit spot | <5% | <10%, minimum achievable<5% |

| Transmission area width | >0.5 DL (diffraction limit) | |

| Transmittance | >98% | >85% @ 400-450 nm >96% @ 450-1700 nm |

| Reflectivity | Ravg<0.5% (0 ° incidence angle) | |

| Diffraction efficiency | >95% | Customization |

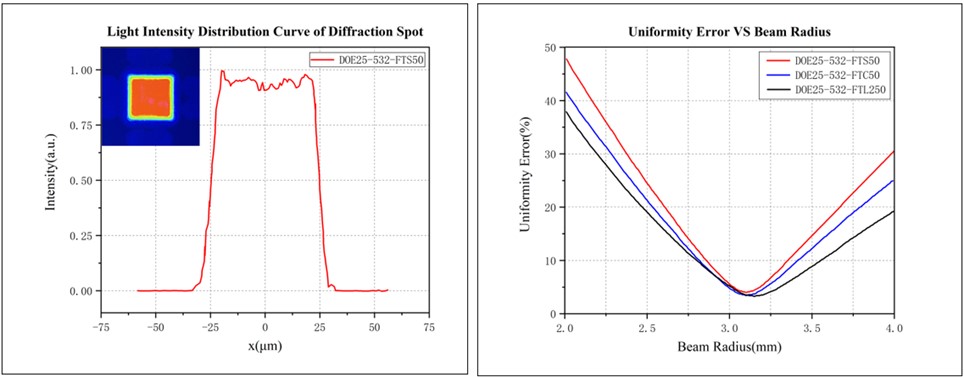

Performance curve

Example of Uniform DOE Application Light Path

1.2 DOE Beam Splitter

Beam splitting DOE often implement the use of either a periodic phase design based on pixel points or a combination of grating cascades to achieve one-dimensional or two-dimensional, odd or even beam splitting effects. The beam splitting DOE we provide is divided into multilayer grating beam splitters and liquid crystal beam splitters. The multilayer grating beam splitter (MLGS) is made of N-BK7 glass substrate and Liquid Crystal Polymers (LCP) material, consisting of three 1-inch double cut edge substrates coated with LCP layers with grating and wave plate structures, and is a single wavelength device. When the incident light is linearly polarized, the multilayer grating beam splitter can achieve one-dimensional or two-dimensional of four splitting based on the relative position relationship of the grating lines at all levels, which is parallel or vertical. The resulting beams are circularly polarized with different rotations, and their beam splitting angle is related to the period of each level of grating. Cascaded gratings have high transmittance, and through better phase design and precise delay control, they have higher beam splitting efficiency and uniformity than typical Dammam grating beam splitters, and can ensure high beam splitting angle accuracy. Our Liquid Crystal Beam Splitter (LCBS) DOE is made of N-BK7 glass substrate and Liquid Crystal Polymers (LCP) material, presenting a typical sandwich flat structure as a single wavelength device. The phase structure of liquid crystal beam splitting DOE is designed based on the principles of diffraction optics, according to the expected beam splitting mode, beam splitting spot spacing, or beam separation angle. The expected beam splitting effect is achieved by allocating the energy of the corresponding diffraction order. Compared with cascaded grating beam splitters, beam splitting DOE has no requirement for the polarization state of the incident light and can achieve odd number beam splitting; Compared with the Dammam grating beam splitter, the beam splitting DOE diffraction efficiency and beam splitting spot uniformity are better; Compared with traditional etching DOE, liquid crystal beam splitting DOE is easier to achieve multi order phase changes, resulting in higher diffraction efficiency and significantly reduced process difficulty. Therefore, based on the advantages of liquid crystal beam splitting DOE, such as high diffraction efficiency, high beam splitting uniformity, high separation angle accuracy, low ineffective diffraction level noise impact, and simple process, it can be used in many application directions, such as parallel laser processing, optical sensor detection, optical aesthetic medicine, to improve processing efficiency and consistency.

The standard beam splitting DOE working wavelength λ we provide are 532nm and 1064nm, with cascaded grating beam splitter beam splitting mode of 1×4 and 2×2 options, LCP beam splitting DOE beam splitting mode has 1×3, 1×9 and 2×3 options. In addition to existing standard products, we also provide flexible customization of various parameter specifications to facilitate users' diverse needs in different application.

Product features

Standard product model

| Product model | Beam splitting mode | Working wavelength/nm | Optical aperture/mm | Beam splitting angle/° |

| SLB-MLGS25-1402-532 | 1x4 | 532 | Ø 20 | 2 |

| SLB-MLGS25-1404-1064 | 1x4 | 1064 | Ø 20 | 4 |

| SLB-MLGS25-2202-532 | 2x2 | 532 | Ø 20 | 2 |

| SLB-MLGS25-2204-1064 | 2x2 | 1064 | Ø 20 | 4 |

| SLB-LCBS25-532-0109-000015 | 1×3 | 532 | Ø 21.5 | 0.5 |

| SLB-LCBS25-532-0109-000015 | 1x9 | 532 | Ø 21.5 | 0.15 |

| SLB-LCBS25-1064-0103-000100 | 1×3 | 1064 | Ø 21.5 | 1 |

| SLB-LCBS25-1064-0109-000030 | 1x9 | 1064 | Ø 21.5 | 0.3 |

| SLB-LCBS25-532-0203-025015 | 2x3 | 532 | Ø 21.5 | 0.25x0.15 |

| SLB-LCBS25-1064-0203-050030 | 2x3 | 1064 | Ø 21.5 | 0.5x0.3 |

Working parameter

| Product type | Standard products | Customization |

| Working wavelength | 532 nm, 1064 nm | 400-1700 nm |

| Component size and installation method | Ø 25.4x2.7 mm, no trimming/dual trimming compatible with 1-inch optical component mounting bracket | |

| Incident beam quality | none | |

| Polarization state of incident beam | Depend on the specific application of the product | |

| Incident beam size | Less than half of the aperture (recommended) | |

| Optical aperture | Ø 20 mm, Ø 21.5 mm | |

| Beam splitting mode | Please refer to the table above for details | 1xm, mxn |

| Beam splitting uniformity | >90% | >90%, maximum achievable>97% |

| Beam splitting angle | Please refer to the table above for details | Adjustable with matching focusing lens |

| Transmittance | >96% | >85% @ 400-450nm, >96% @ 450-1700 nm |

| Reflectivity | Ravg<0.5% (0 ° incidence angle) | |

| Diffraction efficiency | >97% |

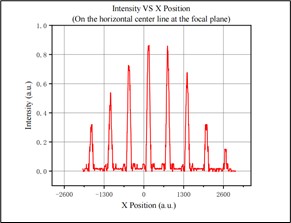

Performance curve

Example of beam splitting DOE application in optical path setup

1.3 DOE Focus Shaping

The focus shaping DOE can modulate the energy distribution of the beam in the z-direction, which can be divided into two effects: long focus depth shaping and multi focus shaping. Commonly used in cutting applications in laser processing to obtain smoother cutting sections and better cutting quality. We provide two types of focal shaping DOEs, namely long focal depth and multi focal depth. The long focal depth DOE is a flat cone lens (PB Axicon, PBA) based on N-BK7 glass substrate and Liquid Crystal Polymers (LCP) material, presenting a sandwich structure of "front and rear are glass substrates, middle is LCP functional film layer. In the LCP layer, the fast axis orientation of liquid crystal molecules shows an equiperiodic gradient distribution along the radial direction of the substrate, and it has the same orientation on the entire device plane λ/ 2 phase delay, for single wavelength devices. Flat cone lenses have polarization related optical properties, and can be used to achieve circular convergence or divergence of light beams depending on the polarization state of the incident beam; When the incident light is left circularly polarized, it can also be used to generate Bessel beams with non diffraction and self recovery characteristics. Compared to traditional conical lenses, our flat conical lenses have a flat structure without a three-dimensional cone tip and are easier to integrate. At the same time, the structural formation of its cone tip depends on the orientation change of liquid crystal molecules, which can achieve processing accuracy at the micrometer level. In addition, it also has the characteristic of large dispersion.

The Multi Focal (MF) DOE is also made of N-BK7 glass substrate and liquid crystal polymer material, consisting of two 1-inch glass substrates and a single layer of LCP layer with design phase, making it a single wavelength device. Multi focal DOE is a diffractive optical element used for focus shaping, which can achieve the axial focusing of incident light into a fixed number, equally spaced, and energy uniform focal points. It uses the diffraction principle of light to design the phase, and through optical orientation, forms a designed phase structure in the liquid crystal polymer film, thereby achieving phase modulation of incident light and dispersing it at different diffraction levels, Finally, use a focusing lens to focus each level to form multiple focal points. Therefore, multifocal DOEs are generally used in conjunction with objective lenses to facilitate the implementation of multifocal requirements in general application scenarios. Multi focus DOE is mainly used for laser depth cutting, such as cutting of transparent glass, sapphire, etc. Compared with traditional laser cutting, it can use a number of uniformly arranged axial focuses to perform depth cutting of materials, so as to achieve an ideal flat section.

We provide 1-inch standard flat cone lenses with working wavelengths of 532nm, 633nm, 1064nm, and deflection angles (half angles) of 0.5°, 1°, 2.0°, 2.3°, and 4.7°. We also provide standard multifocal DOEs with working wavelengths of 1064nm with 3 and 5 focal points. In addition to standard products, we also support flexible customization of parameter specifications to facilitate users' diverse needs in different application scenarios.

Product features

Standard product model

| Product model | Focus shaping type | Working wavelength Nm | Optical aperture Mm | Deflection angle ° | Number of focal points | Focus spacing μm |

| SLB-PBA25-532-05 | long focal depth | 532 | Ø 20 | 0.5 | ||

| SLB-PBA25-532-10 | Long focal depth | 532 | Ø 20 | 1 | ||

| SLB-PBA25-532-23 | Long focal depth | 532 | Ø 20 | 2.3 | ||

| SLB-PBA25-532-47 | Long focal depth | 532 | Ø 20 | 4.7 | ||

| SLB-PBA25-633-05 | Long focal depth | 633 | Ø 20 | 0.5 | ||

| SLB-PBA25-633-10 | Long focal depth | 633 | Ø 20 | 1 | ||

| SLB-PBA25-633-23 | Long focal depth | 633 | Ø 20 | 2.3 | ||

| SLB-PBA25-633-47 | Long focal depth | 633 | Ø 20 | 4.7 | ||

| SLB-PBA25-1064-05 | Long focal depth | 1064 | Ø 20 | 0.5 | ||

| SLB-PBA25-1064-10 | Long focal depth | 1064 | Ø 20 | 1 | ||

| SLB-PBA25-1064-23 | Long focal depth | 1064 | Ø 20 | 2.3 | ||

| SLB-PBA25-1064-47 | Long focal depth | 1064 | Ø 20 | 4.7 | ||

| SLB-LCMF25-1064-F5-3-15 | Multifocal | 1064 | Ø 7.5 | 3 | 15 | |

| SLB-LCMF25-1064-F4-3-4 | Multifocal | 1064 | Ø 5.5 | 3 | 4 | |

| SLB-LCMF25-1064-F5-5-15 | Multifocal | 1064 | Ø 7.5 | 5 | 15 | |

| SLB-LCMF25-1064-F4-5-24 | Multifocal | 1064 | Ø 5.5 | 5 | 24 |

Performance parameter

| product type | Standard - Long focal depth | Customization - Long Focal Depth | Standard - Multi focus | Customization - Multi Focus |

| Working wavelength | 532, 633, 1064nm | 400-1700nm | 1064nm | 400-1700nm |

| Component size and installation method | Ø 25.4x3.2mm, compatible with 1-inch optical component mounting bracket | 3-160 mm (Side length or diameter) | Ø 25.4x3.2 mm, compatible with 1-inch optical component mounting bracket | 3-50.8 mm (Side length or diameter) |

| Requirements for quality of incident light spot | TEM00, M ²< 1.3 | Circular polarized light (recommended) | ||

| Requirements for polarization state of incident light spot | Left circularly polarized light | |||

| Incident spot size | Less than half of the aperture (recommended) | |||

| Optical aperture | Ø 20mm | ≤ substrate inner circle diameter x90% | Ø 5.5mm, Ø 7.5mm | ≤ 10mm |

| Number of focal points | 3 mm, 5 mm | |||

| Focus spacing | 4μm, 15μm, 24μm | |||

| Energy distribution of focal point | Equal proportion | |||

| Uniformity of focal energy | >95% | |||

| Deflection angle | 0.5 °, 1.0 °, 2.3 °, 4.7 ° | 0.2 ° -70 ° | ||

| Transmittance | >97% | >85% @ 400-450nm >96% @ 450-1700nm | >98% | >85% @ 400-450nm >96% @ 450-1700nm |

| reflectivity | Ravg<0.5% (0 ° incidence angle) | |||

| diffraction efficiency | >85% | |||

| Zero order proportion | <4% | |||

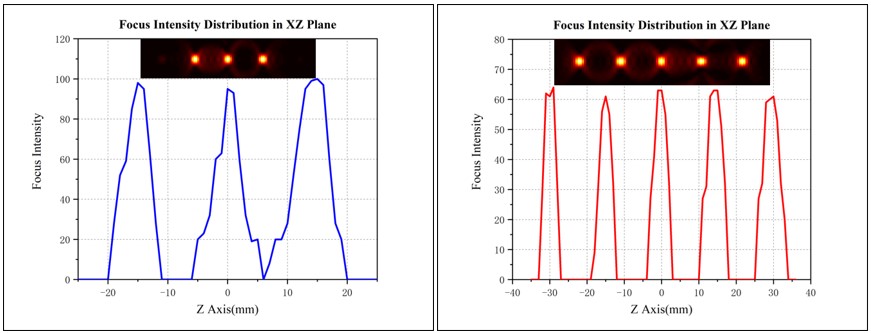

Performance curve

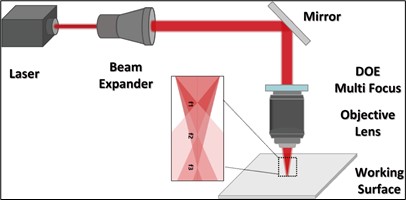

Example of optical path setup for DOE application of focus shaping

1.4 Circular Shaping DOE

Circular shaping DOE can achieve different types of circular shaping effects based on its different phases, such as vortex light generated by vortex wave plates and far-field annular light generated by diffractive cone lens. Among them, vortex light is often used in various applications such as optical tweezers, super-resolution microscopy, lithography, etc; Far field annular light is commonly used in various applications such as atomic trapping, corneal surgery, and laser drilling.

Vortex Retarder (VR) is a sandwich structure based on N-BK7 glass substrate and Liquid Crystal Polymers (LCP) material, presented as a "front and rear glass substrate + middle LCP functional film layer", installed in a standard SM1 lens tube. In the LCP layer, the fast axis orientation of liquid crystal molecules has consistent radial along the substrate but gradually change along the substrate angle. It has the same λ/ 2 phase lag for single wavelength devices. Vortex wave plate has optical polarization properties. Depending on the polarization state of the incident beam, it can be used to generate vector polarized beam or vortex beam with spiral phase wavefront, and can convert TEM00 mode Gaussian beam to Laguerre Gaussian (LG) intensity distribution of "donut hole" (see the technical description for the above optical properties). Compared to traditional optical field control methods, vortex wave plates have the advantages of high efficiency, stability, easy operation, and specialized functionality; Its true zero order characteristics also help achieve lower wavelength sensitivity, higher temperature stability, and a larger incidence angle range.

PB Axicon (PBA) is a sandwich structure based on N-BK7 glass substrate and Liquid Crystal Polymers (LCP) material, presented as a "front and rear glass substrate, middle LCP functional film layer". In the LCP layer, the fast axis orientation of liquid crystal molecules shows an equiperiodic gradient distribution along the radial direction of the substrate. It has the same orientation on the entire device plane λ/2 phase delay for single wavelength devices. Flat cone lenses have polarization related optical properties, and can be used to achieve circular convergence or divergence of light beams depending on the polarization state of the incident beam. Compared to traditional conical lenses, our flat conical lenses have a flat structure without a three-dimensional cone tip and are easier to integrate; At the same time, the structural formation of its cone tip depends on the orientation change of liquid crystal molecules, which can achieve processing accuracy at the micrometer level; In addition, it also has the characteristic of large dispersion.

We provide standard vortex wave plates with working wavelengths ranging from 405 to 1550nm, orders m ranging from 1 to 128, and standard 1-inch flat cone lenses with working wavelengths of 532nm, 633nm, 1064nm, and deflection angles (half angles) of 0.5°, 1°, 2.0°, 2.3°, and 4.7 °. In addition to standard products, we also support flexible customization of parameter specifications to facilitate users' diverse needs in different application scenarios.

Product features

Standard product model

| Product model | Circular shaping type | Working wavelength/nm | Optical aperture/mm | Deflection angle/° | Order m |

| SLB-VR1-532 | Vortex optical field | 532 | Ø 21.5 | 1 | |

| SLB-VR1-633 | Vortex optical field | 633 | Ø 21.5 | 1 | |

| SLB-VR1-1064 | Vortex optical field | 1064 | Ø 21.5 | 1 | |

| SLB-VR2-532 | Vortex optical field | 532 | Ø 21.5 | 2 | |

| SLB-VR2-633 | Vortex optical field | 633 | Ø 21.5 | 2 | |

| SLB-VR2-1064 | Vortex optical field | 1064 | Ø 21.5 | 2 | |

| SLB-VR4-532 | Vortex optical field | 532 | Ø 21.5 | 4 | |

| SLB-VR8-532 | Vortex optical field | 532 | Ø 21.5 | 8 | |

| SLB-VR16-532 | Vortex optical field | 532 | Ø 21.5 | 16 | |

| SLB-VR32-532 | Vortex optical field | 532 | Ø 21.5 | 32 | |

| SLB-VR64-532 | Vortex optical field | 532 | Ø 21.5 | 64 | |

| SLB-VR128-532 | Vortex optical field | 532 | Ø 21.5 | 128 | |

| SLB-PBA25-532-05 | Far-field annular optical field | 532 | Ø 20 | 0.5 | |

| SLB-PBA25-532-10 | Far-field annular optical field | 532 | Ø 20 | 1 | |

| SLB-PBA25-532-23 | Far-field annular optical field | 532 | Ø 20 | 2.3 | |

| SLB-PBA25-532-47 | Far-field annular optical field | 532 | Ø 20 | 4.7 | |

| SLB-PBA25-633-05 | Far-field annular optical field | 633 | Ø 20 | 0.5 | |

| SLB-PBA25-633-10 | Far-field annular optical field | 633 | Ø 20 | 1 | |

| SLB-PBA25-633-23 | Far-field annular optical field | 633 | Ø 20 | 2.3 | |

| SLB-PBA25-633-47 | Far-field annular optical field | 633 | Ø 20 | 4.7 | |

| SLB-PBA25-1064-05 | Far-field annular optical field | 1064 | Ø 20 | 0.5 | |

| SLB-PBA25-1064-10 | Far-field annular optical field | 1064 | Ø 20 | 1 | |

| SLB-PBA25-1064-23 | Far-field annular optical field | 1064 | Ø 20 | 2.3 | |

| SLB-PBA25-1064-47 | Far-field annular optical field | 1064 | Ø 20 | 4.7 |

Working parameter

| product type | Standard - Vortex Light Field | Customization - Vortex Light Field | Standard - Far Field Ring Light Field | Customization - Far Field Ring Light Field |

| Working wavelength | 405-1550nm | 400-1700nm | 532, 633, 1064nm | 400-1700nm |

| Component size and installation method | Ø 25.4x3.2mm, installed in SM1-8A mechanical housing | 3-160mm (Side length or diameter) | Ø 25.4x3.2mm, compatible with 1-inch optical component mounting bracket | 3-160mm (side length or diameter) |

| Order m | 1-128 optional | 1-128 optional | ||

| Requirements for quality of incident light spot | TEM00 | TEM00 | TEM00, M2<1.3 | TEM00, M2<1.3 |

| Requirements for polarization state of incident light spot | Linear polarized light/circularly polarized light | Linear polarized light/circularly polarized light | Circularly polarized light | Circularly polarized light |

| Incident spot size | Depends on the order m | ≤ substrate inner circle diameter x90% | ≤ Optical aperture | ≤ Optical aperture |

| Optical aperture | Ø 21.5 mm | Ø 20 mm | ≤ substrate inner circle diameter x90% | |

| Deflection angle | 0.5 °, 1.0 °, 2.3 °, 4.7 ° | 0.2 ° -7.0 ° | ||

| Transmittance | >85% @ 400-450 nm,>96% @ 450-1700 nm | >85% @ 400-450 nm,>96% @ 450-1700 nm | >97% | >85% @ 400-450 nm, >96% @ 450-1700 nm |

| reflectivity | Ravg<0.5% (0 ° incidence angle) | Ravg<0.5% (0 ° incidence angle) | Ravg<0.5% (0 ° incidence angle) | Ravg<0.5% (0 ° incidence angle) |

| conversion efficiency | >99.5% | >97%, maximum achievable>99.5% | ||

| Zero order proportion | <4% | <4% |

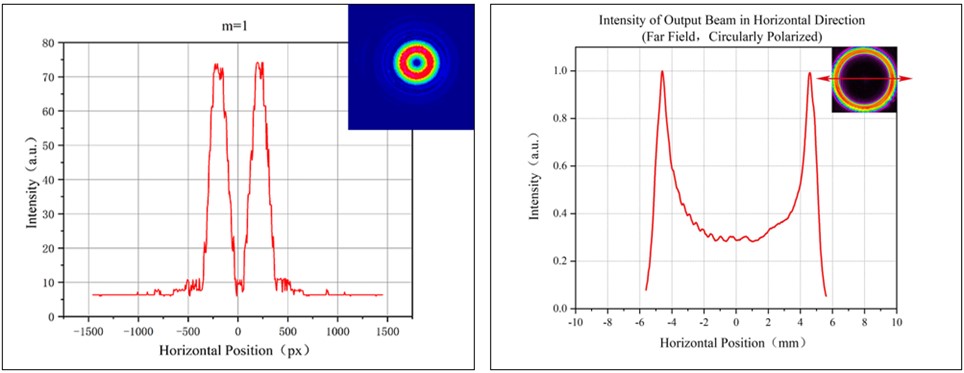

Performance curve

1.5 Lens Array Homogenizers

The lens array homogenizer can achieve non collimated homogenization effects of different shapes of multimode lasers. It can be used for beam homogenization in the direction of Aesthetic medicine, background light homogenization in the direction of machine vision and other scenario.Our lens array homogenizer includes a flat plate microlens array and a flat plate cylindrical lens array. The flat plate microlens array is a flat plate optical element based on the optical diffraction principle of liquid crystal polymers to achieve laser beam homogenization and shaping. It is composed of a polymer film and a single N-BK7 window plate, and uses the array phase distribution on the liquid crystal polymer film to achieve the function of the microlens array. The shape of its outgoing beam is related to various parameters of the microlens unit. By adjusting the phase period and contour of the microlens unit, the divergence angle and spot shape of the outgoing beam can be flexibly controlled, achieving various laser uniform beam and beam shaping requirements of different shapes and sizes. This device is related to the polarization state of the incident light and controls whether the incident light is right or left circularly polarized, which can cause the beam to diverge or converge after passing through the lens. Based on the diffraction principle, the divergence or convergence angle of the lens follows sin θ=λ/ P, in which λ is the design wavelength, p is the radial phase period of a single lens. At the same time, the microlens array is a single wavelength design, free of spherical aberration, and the incident surface is coated with Anti-reflective coating, which has a high transmittance and diffraction efficiency. It can be widely used in various systems such as wavefront sensing, optical energy gathering, and optical shaping. It has great development potential in the fields of optical information processing, optical interconnect, optical computing, image scanners, light field camera, medical devices, 3D imaging and display. Flat column lens array is a flat optical element based on the diffraction optics principle of liquid crystal polymers to achieve one-dimensional beam shaping and homogenization. It is composed of polymer thin films and dual N-BK7 window sheets, and the one-dimensional array phase distribution on the polymer thin film achieve the function of column lens array. Its modulation effect on the beam is related to the polarization characteristics of the incident beam and the parameters of the cylindrical lens unit: by adjusting the incident beam to left circularly polarized light (right circularly polarized light), a right circularly polarized outgoing beam (divergent left circularly polarized outgoing beam) that converges first and then diverges can be obtained, and the divergence or convergence angle follows sin θ=λ/ p. Based on the formula, λ is the design wavelength, p is the phase period of the unit cylindrical lens. By adjusting the phase period of the cylindrical lens unit, the divergence angle of the outgoing beam can be flexibly controlled, achieving one-dimensional shaping and homogenization requirements for different specifications of beams. At the same time, the flat cylindrical lens array is designed with a single wavelength, no spherical aberration, and the incident surface is coated with anti-reflective coating, which has high transmittance and diffraction efficiency. The above characteristics make flat cylindrical lens arrays have great potential in scientific research fields such as imaging, machine vision, and semiconductor laser collimation.

We provide standard microlens arrays with a diameter size of 25.4 mm, microlens focal length of 5 mm and 50 mm, the shape of the outgoing beam is square, and the working wavelengths are 532 nm, 633 nm, 850 nm, 915 nm, and 976 nm. In addition, we also provide multi specification customization services, including special size, working wavelength, beam divergence angle, beam profile and other indicators.

Product features

Standard product model

| Product model | Uniform spot shape | Working wavelength/nm | Focal length/mm | Lens unit size | Optical aperture/mm |

| SLB-PBMLA25S-532-F5 | square | 532 | 5 | 300μmx300 μm | Ø 21.5 |

| SLB-PBMLA25S-532-F50 | square | 532 | 50 | 300μmx300 μm | Ø 21.5 |

| SLB-PBMLA25S-633-F5 | square | 633 | 5 | 300μmx300 μm | Ø 21.5 |

| SLB-PBMLA25S-633-F50 | square | 633 | 50 | 300μmx300 μm | Ø 21.5 |

| SLB-PBMLA25S-850-F5 | square | 850 | 5 | 300μmx300 μm | Ø 21.5 |

| SLB-PBMLA25S-850-F50 | square | 850 | 50 | 300μmx300 μm | Ø 21.5 |

| SLB-PBMLA25S-915-F5 | square | 915 | 5 | 1000μmx1000 μm | Ø 21.5 |

| SLB-PBMLA25S-976-F5 | square | 976 | 5 | 1000μmx1000 μm | Ø 21.5 |

| SLB-PBCLA25-520-8 | linear | 520 | 8 | 0.5mmx25.4mm | Ø 21.5 |

| SLB-PBCLA25-650-8 | linear | 650 | 8 | 0.5mmx25.4mm | Ø 21.5 |

| SLB-PBCLA25-915-5 | linear | 915 | 5 | 1mm x 25.4mm | Ø 21.5 |

| SLB-PBCLA25-940-8 | linear | 940 | 8 | 0.5mmx25.4mm | Ø 21.5 |

| SLB-PBCLA25-976-5 | linear | 976 | 5 | 1mm x 25.4mm | Ø 21.5 |

Working parameter

| Product type | Standard - Microlens Array | Customization - Microlens Array | Standard - Column lens array | Customization - Column Lens Array |

| Working wavelength | 532, 633, 850, 915, 976 nm | 400-1700 nm | 520, 650, 915, 940, 976 nm | 400-1700 nm |

| Component size and installation method (Side length or diameter specifications) | Ø 25.4x1.6 mm, compatible with 1-inch optical component mounting bracket | 3-160 mm (side length or diameter specifications) | Ø 25.4x3.2 mm, compatible with 1-inch optical component mounting bracket | 3-160mm (Side length or diameter specifications) |

| Optical aperture | Ø 21.5 mm | ≤ substrate inner circle diameter x90% | Ø 21.5 mm | ≤ substrate inner circle diameter x90% |

| Requirements for quality of incident light spot | multimode | |||

| Requirements for polarization state of incident light spot | nothing | |||

| Incident spot size | Please consult us | |||

| focal length | 5 mm, 50 mm | Please consult us | 5 mm, 50 mm | Please consult us |

| Shape of outgoing light spot | square | Any shape such as square, triangle, regular hexagon, etc., can achieve the best shape for dense splicing | linear | linear |

| non-uniform of outgoing light spot | <10% | |||

| Transmittance | >85% @ 400-450 nm,>96% @ 450-1700 nm | |||

| Reflectivity | Ravg<0.5% (0 ° incidence angle) | |||

| Diffraction efficiency | >98% | |||

Performance curve

2.1 Bessel Processing Heads

The Bessel processing head is an optical module used for laser processing system terminals, composed of refractive and diffractive optical elements integrated into a metal mechanical sleeve. Through the light field control effect of the conical lens and the beam shaping effect of the double telecentric optical system, it can generate Bessel beams that meet the requirements of laser processing. Bessel processing head is suitable for single mode lasers. The optical components are made of high transmittance substrate, which has a high energy utilization rate. The compact modular structure is easy to integrate and has good adaptability to various laser processing systems. Through unique optical design, very small aberrations can be achieved. The size of the main lobe at the center of the outgoing light spot is <Ø 2μm. It can achieve small edge collapses, small heat affected areas, and non tapered cutting effects within a depth range of 0.2mm-12mm (including customization). At present, there are Bessel machining head standards designed with a working wavelength of 1064nm with an air focal depth of 0.5, 1, 2, 4, 6, and 8mm. They also support flexible customization of parameter specifications to facilitate users' diverse needs in different application scenarios.

Product features

Standard product model

| Product model | Design wavelength/nm | Incident aperture/mm | Air focal depth/mm | Spot size/ μm |

| SLB-BPH-1064-6-05 | 1064 | Ø 6 | 0.5 | Ø 0.74 |

| SLB-BPH-1064-6-1 | 1064 | Ø 6 | 1.0 | Ø1.28 |

| SLB-BPH-1064-6-2 | 1064 | Ø 6 | 2.0 | Ø 1.2 |

| SLB-BPH-1064-8-4 | 1064 | Ø 8 | 4.0 | Ø1.47 |

| SLB-BPH-1064-10-6 | 1064 | Ø 10 | 6.0 | Ø 1.54 |

| SLB-BPH-1064-10-8 | 1064 | Ø 10 | 8.0 | Ø 1.67 |

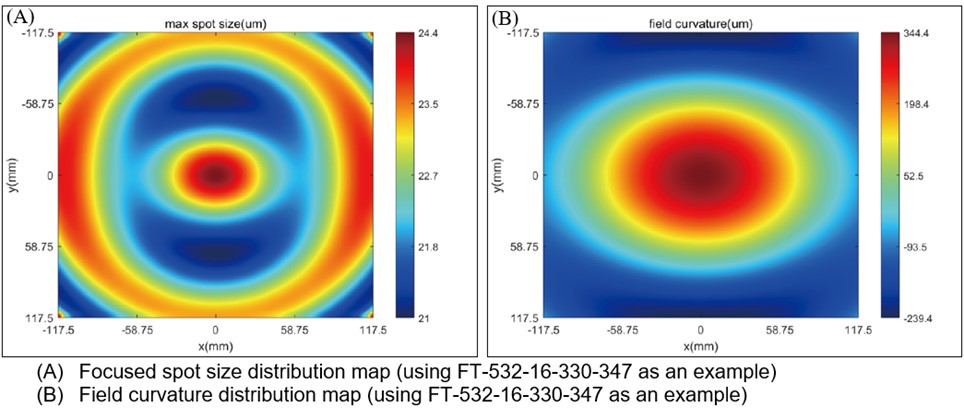

2.3 F-theta Field Lenses

F-theta field lens is a flat field scanning lens that uses high transmittance optical glass as the substrate and is composed of a lens group integrated into a mechanical shell with a specific design scheme. The height of its focused beam is f ×θ (θ is the angle of incidence of the incident beam). Angular velocity of input beam is directly proportional to the angular velocity of the output beam, enabling the scanning mirror to operate at a constant angular velocity. It is commonly used to improve the ability of the edge beam to incident on the detector, homogenize the non-uniform light on the photosensitive surface of the detector, and compensate for the field curvature and distortion of the system. The F-theta field mirror can provide a flat field image plane when used, while greatly simplifying the control circuit. It has the characteristics of high transmittance, large scanning range, low aberration, and low F-theta distortion. It has great development potential in micro processing of medium and low laser power, such as marking machines, engraving machines, laser printers, fax machines, printing machines, laser pattern generators for semiconductor integrated circuits, and laser scanning precision equipment.

Product features

Standard product model

| Product model | Design wavelength/nm | Incident aperture/mm | Focal length/mm | Scanning field/mm | Material quality |

| SLB-FT-532-16-330-347 | 532 | Ø 16 | 330 | 245X245 | optical glass |

| SLB-FT-1064-15-347-355 | 1064 | Ø 15 | 347 | 253.4X253.4 | optical glass |

| SLB-HPFT-532-14-330-230 | 532 | Ø 14 | 330 | 110x110 | optical glass |

| SLB-FT-1064-12-160-160 | 1064 | Ø 12 | 160 | 160x160 | Fused silica |

2.3 Customization of Micro/nano Optical Components

Micro nano optical elements, also known as diffractive optical elements, refer to optical elements that are fabricated in various ways on a flat substrate surface to produce two-dimensional structures at the micron and nanometer scales. Micro/nano optical elements transform the incident beam into any spot shape with the highest efficiency. According to different functions, micro/nano optical components can be basically divided into three categories: beam shaping devices, beam splitters, and homogenizers. Laser direct writing technology is one of the main technologies for producing micro/nano optical components. Various structures can be achieved by modulating the exposure beam power density, beam size, and polarization state. Based on the production process of liquid crystal micro/nano products, we can currently prepare various types of liquid crystal micro/nano optical components with working wavelengths in the range of 400-2000nm. Based on different structures, the minimum feature size can reach 5-0.2 μm. The phase structure can be flexibly processed, and can basically prepare either one-dimensional or two-dimensional phase structure. The device also supports multiple thicknesses and apertures in terms of external dimensions.