Shijiazhuang Zhongtai Pipe Technology Development Co., Ltd |

|

ERW165 welded pipe production line/pipe making machine /tube mill is designed to produce welded pipes of 76mm-165mm in OD and 2.0mm-6.0mm in wall thickness and corresponding square and rectangular pipe. This production line is suitable for producing GI, carbon steel, and API tubes for metallurgy, construction, transportation, machinery, and vehicle industries. After absorbing advanced pipe-making technology from both abroad and domestic, our innovative designed production line and every single unit of the production line are economical and practical.

Equipment Advantages

| Steel Pipe Specification | |

| Round Pipe diameter | Ø76–Ø165mm |

| Pipe Thickness | 2.0– 6.0mm |

| Pipe Length | 6-12m |

| Length Tolerance | 0-6mm |

| Steel Tape Specification | |

| Material | Carbon steel (δb≤500Mpa, δs≤235Mpa) |

| Inner diameter | Φ470-Φ510mm |

| Outer diameter | Φmax=1900mm |

| Strip steel width | 40x40mm-90x90mm |

| Strip steel thickness | 1.5mm-4.5mm |

| The maximum weight | 3.0 tons |

| Electric installed capacity | appro.450KW |

| Line Speed | 1.5m3/h |

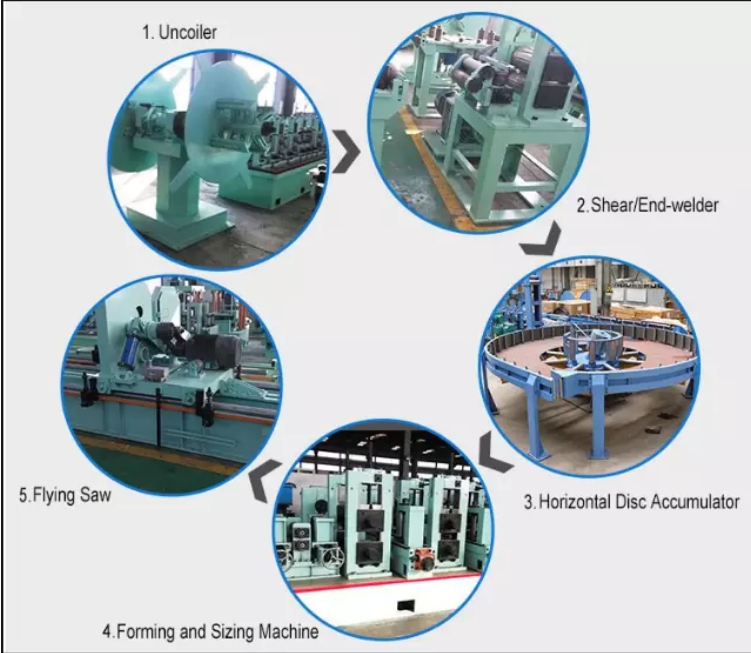

Technical Flow

{SteelTape}→→ Double-head un-coiler →→Strip-head Cutter and welder→→Spiral accumulator→→Forming section (Flattening unit +Main driving unit +Forming unit +Guide unit +High frequency induction welding unit +squeeze roller) + De-burr frame →→Cooling unit →→ Sizing unit and straightener →→Cold saw under computer-control →→ Run-out table→→ Semi-auto Packing machine

| Packing & Delivery | |

| Packing | 1.We wrap the machine with film, then covered it with one wooden case. |

| 2.Wooden case and pallets will be used subject to different models and shipping methods. | |

| 3.customized package solutions offered as per customer requirements. | |

Q: Are you a manufacturer?

A: Yes, we are a manufacturer. We have 4 factories ( Machining,

Assembling, Heat treatment, and Moulding ). We also have our own

R&D department. Welcome to visit us.

Q: What kind of payment term do you do?

A: We do T/T and L/C.

Q: What info do you need before giving me the price and proposal?

A: Since we design individual machines based on our customer's

requirements, we need your desired products' basic dimensions,

including all the pipe diameter(or tube length), thickness range,

usage, raw material steel grade, coil weight, and degree of

automation.

Q: What should I do if I just start a new business?

A: Contact us immediately, we provide a free consultant for

pre-sales service. Also, we can help you solve the raw material

(steel coil) purchase, worker training, international market price,

and more.

Q: How do you do QA?

A: We have a special team to do strict QA, this is one of our

strengths:

(1)Every gearbox will be tested for 8 hours with oil inside to

guarantee there is no leak.