Shijiazhuang Zhongtai Pipe Technology Development Co., Ltd |

|

Tube Manufacturing Equipment Metal Duct Producing Mill Steel Pipe Production Line

Product Description

ERW60 high frequency longitudinal welded pipe production line is designed to produce welded pipes of 20mm-50mm in OD and 0.8mm-3.0mm in wall thickness, as well as corresponding square and rectangular pipe.

Application:GI, carbon steel and stainless steel tubes for metallurgy, construction, transportation, machinery and vehicle industries.

Technical Flow Of The Production Line

Steel Tape →→ Double head uncoiler →→ Strip-head Cutter and welder →→ Spiral accumulator →→ Forming section (Flattening unit +Main driving unit +Forming unit +Guide unit +High frequency induction welding unit +squeeze roller) + De-burr frame →→ Cooling unit →→ Sizing unit and straightener →→ Cold saw under computer-control →→ Run-out table →→ Packing machine

Product Parameter

| Steel Pipe Specification | |

| Round Pipe diameter | Ø20–Ø60mm |

| Pipe Thickness | 0.8 – 3.0mm |

| Square and rectangle pipe | 15x15mm – 50X50mm |

| Pipe Thickness | 0.8 – 2.0mm |

| Pipe Length | 6-12m |

| Length Tolerance | 0-3mm |

| Steel Tape Specification | |

| Material | Carbon steel (δb≤500Mpa, δs≤235Mpa) |

| Inner diameter | Φ450-Φ520mm |

| Outer diameter | Φmax=1500mm |

| Strip steel width | 65mm-190mm |

| Strip steel thickness | 0.8mm-3.0mm |

| The maximum weight | 1.0-2.0 tons |

| Electric installed capacity | appro.65KW |

| Line Speed | 20-120m/min |

Product Display

Product Details

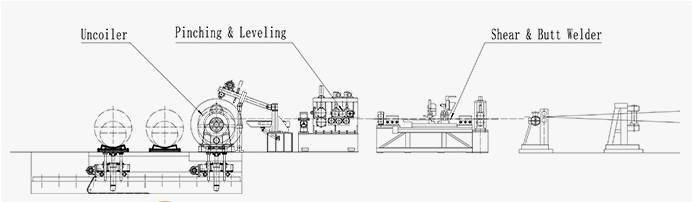

1. Double heads Decoiler (Hydraulic model)

It is used to support the coil and provide raw materials for the

production line. The reel is cantilever type.

2. Shearing & Welder

To connect the strips after cutting the preceding coil tail end and

the succeeding coil top end and being welded together by CO2 gas

shielding welding to keep the Pipe Welding Line running

continuously.

3.Horizontal accumulator

Storage of steel coil, Advantage: The feeding is more stable,

without bending, while reducing the resistance of the feeding, it

will not cause damage to the galvanized layer surface, and the

noise is relatively lower.

4.Forming and Sizing Machine

The steel strip of a certain width is bent into corresponding

specifications of round pipe, rectangular pipe or open profile

through roll forming.This unit consists of five parts: forming

machine, welding machine, cooling part, sizing machine, and

straightening machine.

5.High Frequency Welding Equipment

Tube Mill High Frequency Welder is specially designed for straight

seam welding.The high power capacitor C and inductor coil L compose

current-mode parallel upper-voltage resonance circuit, which

doesn’t need output transformer.

6. Cooling

Cool down quickly, Fixed welded pipe shape

7. Cold Flying Saw

Cut pipe, Low inertia DC motor through mechanical transmission

device, measuring, calculate and driving saw car at the same speed

with the high-speed running pipe, then cut off the pipe with

specified length.

8. Run out table(Stacking Packing Machine)

It’s a packaging equipment designed especially for steel pipe

industry, which can realize automatic stacking the tubes or pipes

into hexagonal or square shapes, and then Automatic bundling,

Sloping, Digital Weighter

9.Straightening device

Straightening of finished pipes with sizing, The upper, lower, left

and right positions of the vertical roller of the straightening

machine can be adjusted to ensure the outer diameter of the

finished rigid tube

About Us

Q:Are you manufacturer?

A:Yes,we are manufacturer. We have 4 factories ( machining,

assembling, heat treatment,and mould factory)And we have our own

R&D department. Welcome to visit us.

Q:What kind of payment term you can do?

A: We can accept T/T and L/C.

Q:What info you need before you make the proposal?

A:The pipe diameter , thickness range , usage, raw material steel

grade, coil weight and automatic degree.

Q: What should I do if I just start a new business?

A:Contact us immediately ,we provide free consultant for pre-sales

service .Also we can help you to solve the raw material (steel

coil) purchase,worker training,international market price.

Q:How do you do QA?

A:We have special team to do strict QA,this is one of our

strengths:

(1)Every gear box will be tested for 8 hours with oil inside to

guarantee there is no leak.

(2)Every shaft will be inspected for the centering jumpiness.

(3)Every roller will be checked to make sure its in the range of

tolerance critical parts will be inspected for all dimensions.

Q:Why I should choose you,what are the differences between you and

other Chinese suppliers?

A:We are concentrate on this industry for more than 20 years,and

especially in pipe making machines. Our pipe making machine line

directly export to Russia,Vietnam,lndia,Indonesia,and many other

countries in Asia, Africa, middle east and South America.