SHANDONG SMART MACHINERY CO., LTD. |

1.Introduction of Dog Treat Pet Chewing Gum Equipment

Pet treats machine takes starch as raw materials with scientific configuration and was extruded from co-extruder, it can be made into many kind of shapes such as stick,bone ect. This kind of food not only provide protein,fat,vitamin ,nutrition for dogs, but also satisfy the dog nature hobby. It has following features: strong teeth,clean mouth and teeth. The products can be in many shapes, like twist, double colors, core-filling and so on

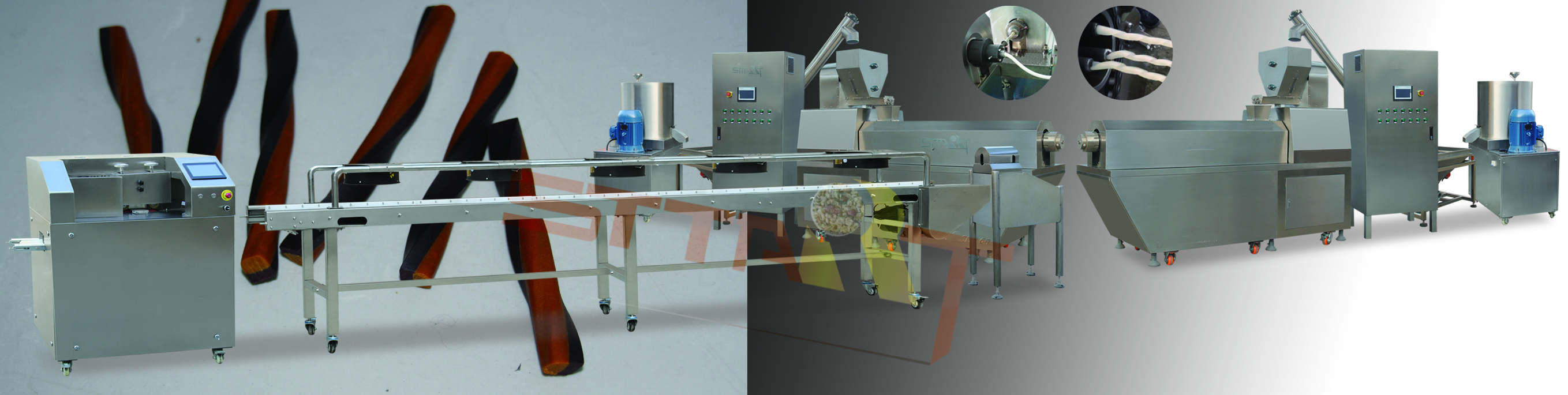

2. Equipments List:

Mixer--- Screw Conveyor--- Single-Screw Extruder---cooling

conveyor---cutter--cooling conveyor

Mixer--- Screw Conveyor--- 2 sets* Single-Screw Extruder---twist machine ---cooling conveyor---cutter--cooling conveyor

The solution was a single-screw machine for dog food processing, with a co-extrusion die and cutter that was custom built for their process. material be forced positively into the screw, eliminating potential ‘dead areas’ where the material could have dried or coagulated. A flower-shaped dog treat with a medicinal center was produced, that looked good and retained its unique shape very well.

3. Technical Parameter of the pet treats machine:

| Model | SRD-100 | SRD-300 |

| Capacity | 100-150kg/hr | 200-300kg/hr |

| Power | 81kw | 95kw |

| Dimension | 18 x 5 x 3m | 20 x 5 3m |

| Workers Needed | 1-2 | 1-2 |

3.Process of Pet Treats Chews Dog Food :

a) Mixing materials

b) Extruding different shape Pet Treats Chews Dog Food by changing the die

c) Cooling to remove moisture

d) Cutting the pet treats in regular length

f) Packing

4. Use of the pet treats machine:

The use of pet food extrusion equipment in the pet supplies industry is widespread and established, mainly due to the following benefits of the production process:

Fast:

Pet food extruders operate continuously, yielding high quantity to meet strict production deadlines. Diamond America extruders are designed for fast, easy changeover and cleaning between runs.

Flexible:

Extrusion pet food manufacturing is adaptable, for application to a wide range of input material types. Also, extrusion can produce many different forms of final product in terms of shape, texture and color.

Consistent:

Pet food extrusion and cutting produces a very uniform end product of constant cross section and size. The process is extremely controllable and reliable, allowing high quality to be maintained throughout.

Efficient

The highly repeatable extrusion process is low in cost, especially

once conditions have been optimized. Precise process control and

automation reduces waste and boosts productivity.

Pet food extrusion equipment can be used on all forms of manufactured feed: dry food (sometimes called kibble), semi-moist products and treats. Common pet food ingredients include flour, meal, grits, meat, fats, minerals, amino acids and vitamins, often with the addition of flavor enhancers, texturing agents and preservatives.

The growing industry dictates frequent product changes, both in ingredients and aesthetics, to suit market trends and demands. The adaptability of pet food extrusion equipment easily accommodates process innovation and variation, without significant changes in machine configuration.

Pet food extrusion equipment can be used on all forms of manufactured feed: dry food (sometimes called kibble), semi-moist products and treats. Common pet food ingredients include flour, meal, grits, meat, fats, minerals, amino acids and vitamins, often with the addition of flavor enhancers, texturing agents and preservatives.

The growing industry dictates frequent product changes, both in ingredients and aesthetics, to suit market trends and demands. The adaptability of pet food extrusion equipment easily accommodates process innovation and variation, without significant changes in machine configuration.

Production Line pictures and sample pictures:

Test Videos:

Any interest, please contact us for detail quotation!

smart2@smartmachinery.cn/ whatsapp: +8615153189382