Shijiazhuang Minerals Equipment Co. Ltd |

|

CNSME SH/250ST (12/10) Slurry Pump is robust state of the art slurry pumps that feature oil or grease lubrication bearing assemblies and complete interchangeable with other major brands. The 10 inch centrifugal slurry pump can be supplied in high chrome alloy materials specifically designed for heavy duty slurry applications.

CNSME SH/250ST (12/10) slurry pump wet parts are made of wear-resistant high chromium alloy.

CNSME SH/250ST (12/10) pump bearing assembly use cylindrical structure, adjusting the space between impeller and front liner easily, Can be removed completely when being repaired. Bearing assembly use grease lubrication.

The shaft seal could use the packing seal, expeller seal and mechanical seal for all slurry pump.

The discharge branch can be positioned at intervals of 45 degrees by request and oriented to any eight positions to suit installations and applications at its working site.

There are the drive types, such as V belt drive, gear reducer drive, fluid coupling drive, and frequency conversion drive devices.

Wide performance, good NPSH and high efficiency.

The CNSME SH/250ST (12/10) slurry pump can be installed in multistage series to meet the delivery for long distance.

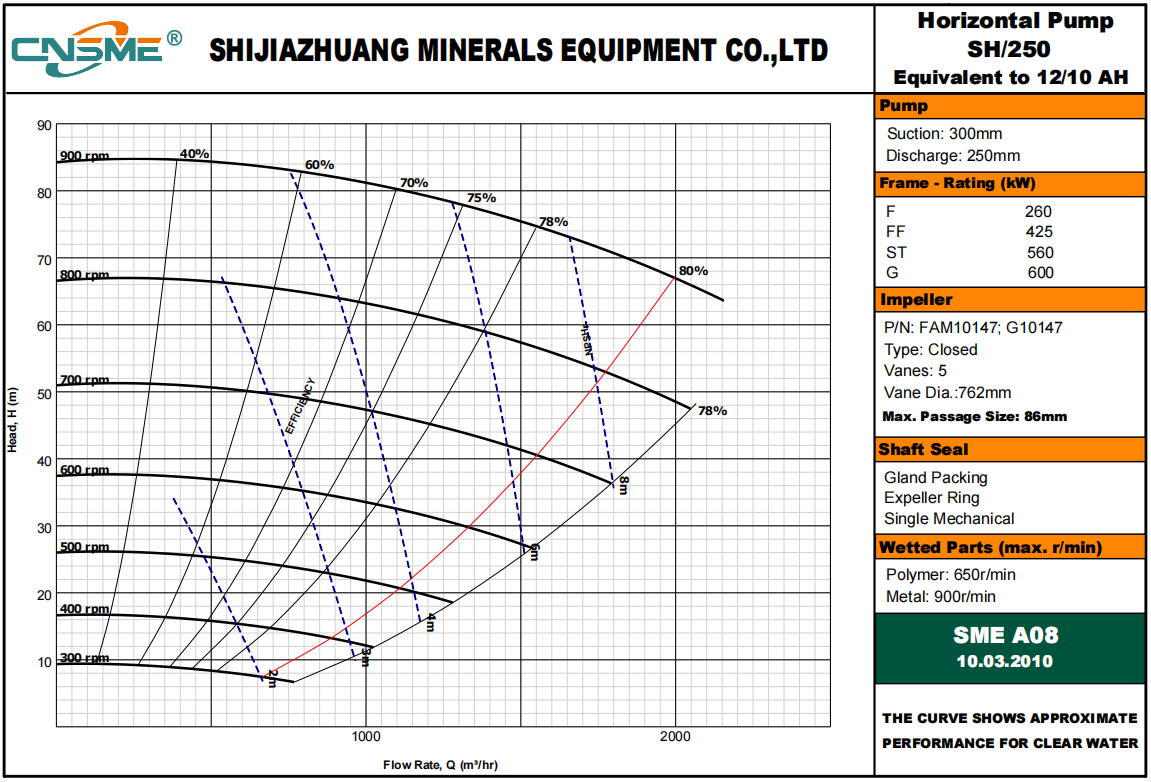

3.Performance Curve of CNSME® SH/250ST (12/10ST-) Slurry Pump:

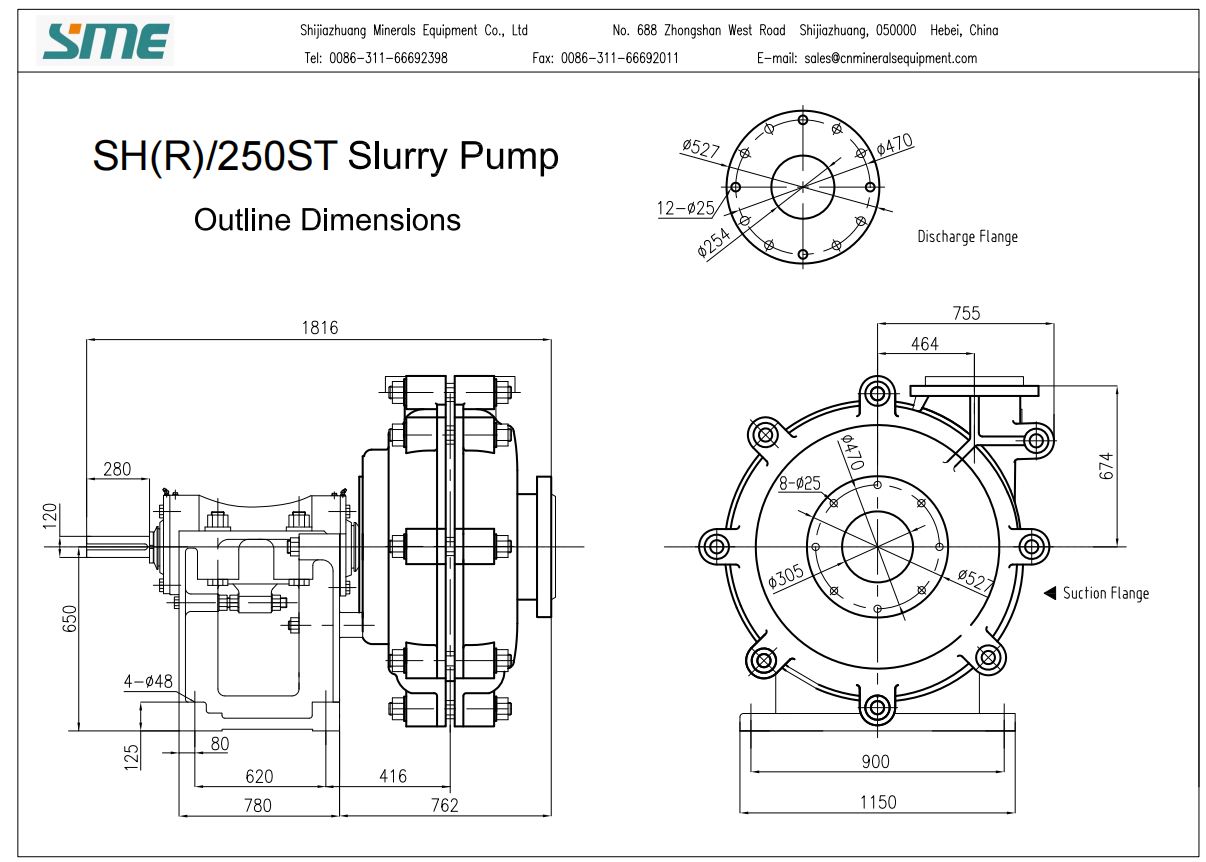

4. Dimensional Drawing of CNSME® SH/250ST (12/10ST-) Slurry Pump:

The Slurry Pumps are widely used to transport corrosive/ abrasive and high concentration slurry in many industries. such as Gold, Silver, Iron ore, Tin, Steel, Coal, Titanium, Copper, Mineral sands, Lead and Zinc. Various other industries include Molybdenum, Electric Utilities, Oil Shale, Water & Sewage Utilities, Building areas, Sand & Gravel, Tobacco and Agriculture (hog, poultry, dairy manure), Mining & Minerals, Grinding and screening, Hydrocyclone separation, Magnetic separation, Flotation, Thickening, Filtration, Leaching, solvent extraction and electrowinning, Pelletizing, Tailings, Metallurgy, Roasting, Annealing and pickling, Coke quenching, Hot strip milling, Neutralisation, Mud handling and waste treatment.