Shijiazhuang Minerals Equipment Co. Ltd |

|

CNSME SH heavy-duty slurry pumps are end-suction, split-case, centrifugal pumps designed for heavy-duty abrasive applications with large shaft diameter, heavy-duty bearing assemblies, and robust slurry pumping capacity. CNSME® 3/2 C Slurry Pump with CV Drive Arrangement and 11kw Electric motors are ready for the mineral processing plant, The wet parts of the 3/2 slurry pumps are made from standard ultra-chrome alloy A05A. the seal arrangement is gland water.

| Model | Max.Power (kw) | Materials | Clear water performance | Impeller Vane No. | |||||

| Liner | Impeller | Capacity Q( m3/h) | Head H( m) | Speed n (rpm) | Eff.η (%) | NPSH (m) | |||

| 3/2C | 30 | Metal | Metal | 39.6-86.4 | 12-64 | 1300-2700 | 55 | 4-6 | 5 |

| Rubber | Rubber | 36-75.6 | 13-39 | 1300-2100 | 2-4 | ||||

Design Features:

√ Bearing assembly- large diameter shaft with short overhang contributes to long bearing life.

√ Liners – easily replaceable liners are bolted, not glued to the casing for positive maintenance.

√ Casing – casing halves of cast or ductile iron provide high operating pressure capabilities.

√ Impeller – front and rear shrouds have pump out vanes that reduce recirculation and seal contamination.

√ Throat bush – wear is reduced and maintenance simplified by the use of tapered

CNSME SH Slurry Pump is available in a wide range of sizes and models, with a variety of metal, rubber, polyurethane, and ceramic wet parts options, an assortment of seal arrangements, and a standard impeller adjustment mechanism incorporated into every base or assembly.

The 3/2C- mud pump is designed to handle the toughest and most abrasive applications including mining, mineral processing, power generation, aggregate processing, and any other type of mud pumping application.

Typical applications include:

3/2 C Slurry Pump is suitable for processing the high abrasion

slurry or the material containing solid particles.

Mineral Processing, Metal smelting plant: convey slurry.

Sand plant: transporting and conveying sand and gravel, feeding

sand and water all types of classification and dewatering plants.

Coal preparation plant: classifying, screening and conveying heavy

medium, conveying coal pulp.

Ceramics and glass factory: porcelain clay and sandstone

transportation, feeding hydrocyclone and effluent disposal etc.

Steel works: conveying slurry, rust and corrosive liquid etc.

Irrigation systems and dredging: silt removal in dams and river

bed, sand classifying.

Note: please specify if applied where oil and chemicals are

contained

Other type about :

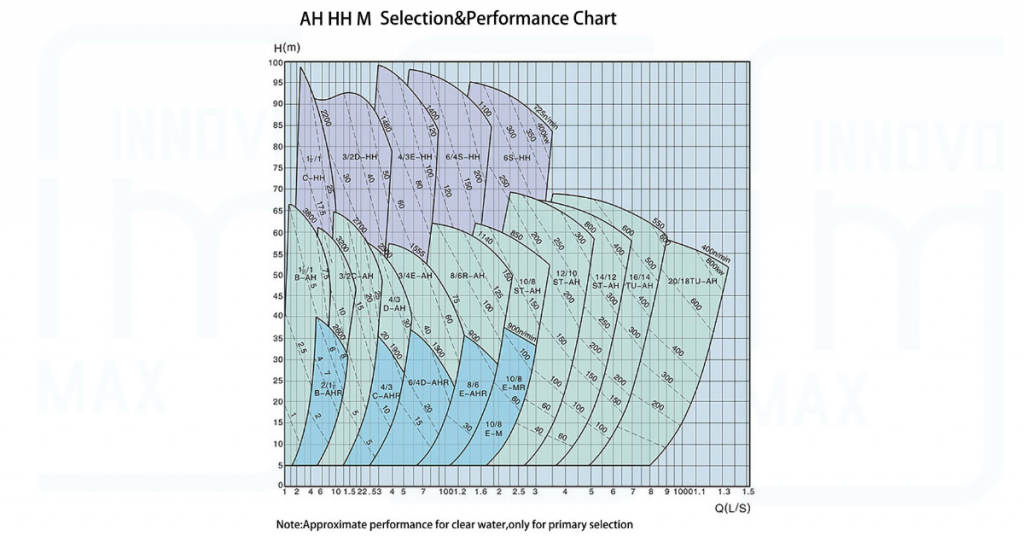

Pump Model | Allowable Max. Power (kW) | Capacity Q (m 3 /h) | Capacity Q (l/s) | Head H (m)

| Speed n (r/min) | Max.Eff.(%) | NPSH (m) | Impeller. Dia. (mm) |

|---|---|---|---|---|---|---|---|---|

| 1.5 / 1 B - | 15 | 12.6-28.8 | 3.5-8 | 6-68 | 1200-3800 | 40 | 2-4 | 152 |

| 2 / 1.5 B - | 15 | 32.4-72 | 9-20 | 6-58 | 1200-3200 | 45 | 3.5-8 | 184 |

| 3 / 2 C - | 30 | 39.6-86.4 | 11-24 | 12-64 | 1300-2700 | 55 | 4-6 | 214 |

| 4 / 3 C - | 30 | 86.4-198 | 24-55 | 9-52 | 1000-2200 | 71 | 4-6 | 245 |

| 4 / 3 D - | 60 | 86.4-198 | 24-55 | 9-52 | 1000-2200 | 71 | 4-6 | 245 |

| 6 / 4 D - | 60 | 162-360 | 45-100 | 12-56 | 800-1550 | 65 | 5-8 | 365 |

| 6 / 4 E - | 120 | 162-360 | 45-100 | 12-56 | 800-1550 | 65 | 5-8 | 365 |

| 8 / 6 E - | 120 | 360-828 | 100-230 | 10-61 | 500-1140 | 72 | 2-9 | 510 |

| 8 / 6 R - | 300 | 360-828 | 100-230 | 10-61 | 500-1140 | 72 | 2-9 | 510 |

| 10 / 8 ST - | 560 | 612-1368 | 170-380 | 11-61 | 400-850 | 71 | 4-10 | 686 |

| 12 / 10 ST - | 560 | 936-1980 | 260-550 | 7-68 | 300-800 | 82 | 6 | 762 |

| 14 / 12 ST - | 560 | 1260-2772 | 350-770 | 13-63 | 300-600 | 77 | 3-10 | 965 |

| 16 / 14 TU - | 1200 | 1368-3060 | 380-850 | 11-63 | 250-550 | 79 | 4-10 | 1067 |

| 20 / 18 TU - | 1200 | 2520-5400 | 700-1500 | 13-57 | 200-400 | 85 | 5-10 | 1370 |

| 1.5 /1 B -(R) | 15 | 10.8-25.2 | 3-7 | 7-52 | 1400-3400 | 35 | 2-4 | 152 |

| 2 / 1.5 B - (R) | 15 | 25.2-54 | 7-15 | 5.5-41 | 1000-2600 | 50 | 2.5-5 | 178 |

| 3 / 2 C - (R) | 30 | 36-75.6 | 10-21 | 13-39 | 1300-2100 | 55 | 2-4 | 213 |

| 4 / 3 C - (R) | 30 | 79.2-180 | 22-50 | 5-34.5 | 800-1800 | 59 | 3-5 | 245 |

| 4 / 3 D - (R) | 60 | 79.2-180 | 22-50 | 5-34.5 | 800-1800 | 59 | 3-5 | 245 |

| 6 / 4 D - (R) | 60 | 144-324 | 40-90 | 12-45 | 800-1350 | 65 | 3-5 | 365 |

| 6 / 4 E - (R) | 120 | 144-324 | 40-90 | 12-45 | 800-1350 | 65 | 3-5 | 365 |

| 8 / 6 E - (R) | 120 | 324-720 | 90-200 | 7-49 | 400-1000 | 65 | 5-10 | 510 |

| 8 / 6 R - (R) | 300 | 324-720 | 90-200 | 7-49 | 400-1000 | 65 | 5-10 | 510 |

| 10 / 8 ST - (R) | 560 | 540-1188 | 150-330 | 12-50 | 400-750 | 75 | 4-12 | 686 |

| 12 / 10 ST -(R) | 560 | 720-1620 | 200-450 | 7-45 | 300-650 | 80 | 2.5-7.5 | 762 |

| 14 / 12 ST - (R) | 560 | 1152-2520 | 320-700 | 13-44 | 300-500 | 79 | 3-8 | 965 |

| 16 / 14 TU - (R) | 1200 | 1224-2754 | 340-765 | 9-43 | 250-450 | 82 | 3-8 | 1067 |

| 20 / 18 TU - (R) | 1200 | 2268-4860 | 630-1350 | 11-46 | 200-350 | 82 | 2-8 | 1372 |

| 10 / 8 E - M | 120 | 540-1440 | 150-400 | 14-60 | 600-1000 | 73 | 4-10 | 549 |

| 10 / 8 R - M | 300 | 540-1440 | 150-400 | 14-60 | 600-1000 | 73 | 4-10 | 549 |

| 1.5 / 1 C -HH | 30 | 16.2-34.2 | 4.5-9.5 | 25-92 | 1400-2200 | 20 | 2-5.5 | 330 |

| 3 / 2 D -HH | 60 | 68.4-136.8 | 19-38 | 25-87 | 850-1400 | 47 | 3-7.5 | 457 |

| 4 / 3 E -HH | 120 | 126-252 | 35-70 | 12-97 | 600-1400 | 50 | 2-5 | 508 |

| 6 / 4 F - HH | 260 | 324-720 | 90-200 | 30-118 | 600-1000 | 64 | 3-8 | 711 |

| 8 / 6 S - HH | 560 | 468-1008 | 130-280 | 20-94 | 500-1000 | 65 | 4-12 | 711 |