Shijiazhuang Shiza Pump Industry Co.,Ltd. |

|

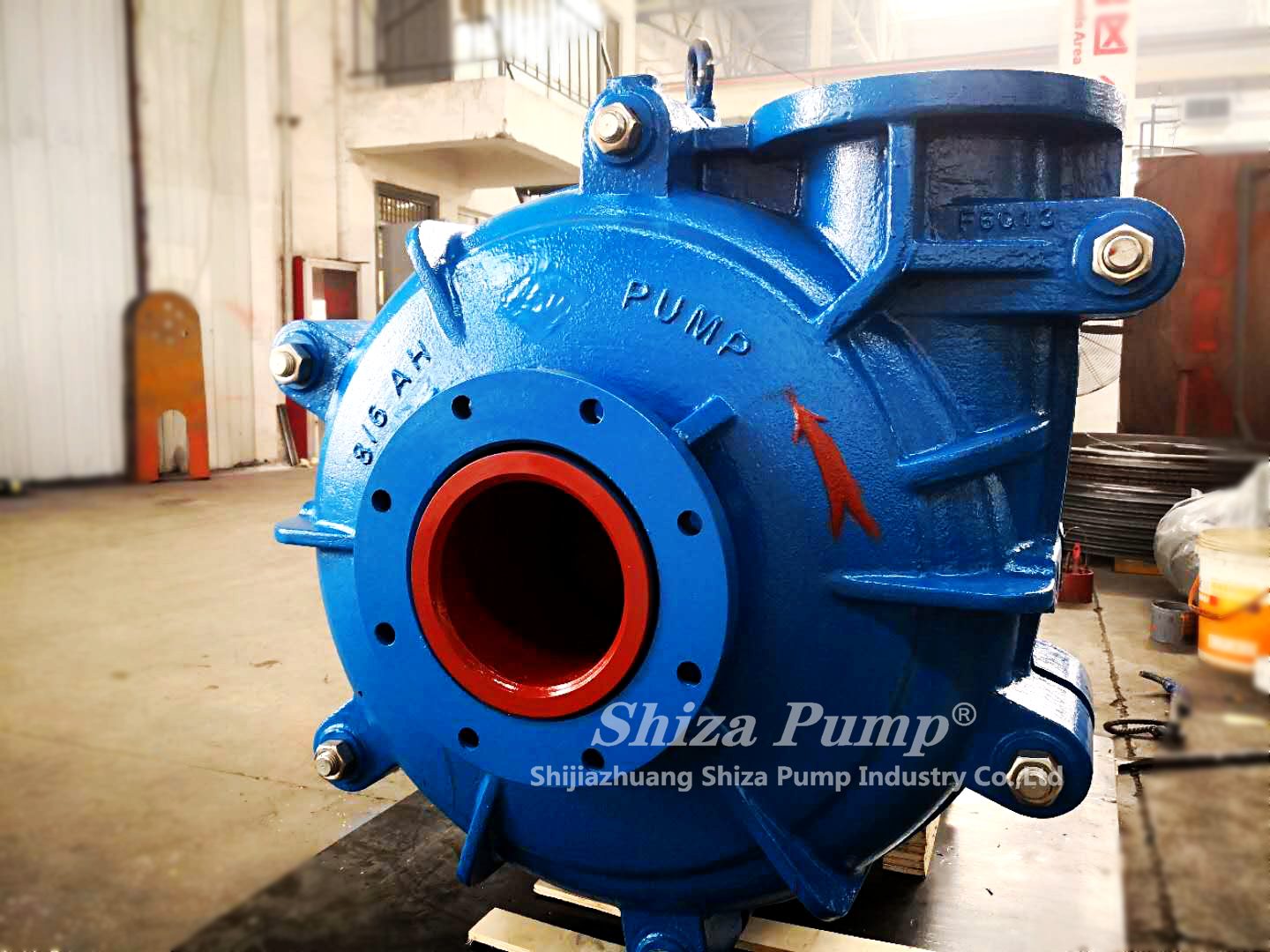

Product introduction

The 3 / 2 C - Centrifugal Slurry Pump is a horizontal, vertical open, double pump housing construction with a replaceable metal lining or rubber lining for the pump body and pump cover. The lining can be used for wear through. Up to now, there is no need to replace, extend the maintenance cycle and reduce operating costs.

The 3 / 2 C - can also be called a heavy-duty slurry pump. Because the pump has thick bearing parts and heavy brackets, it is suitable for conveying strong abrasion, high-concentration slurry or low-concentration high-lift slurry. It can be used in multiple stages within the maximum allowable working pressure of the pump Use in series.

The 3 / 2 C - Centrifugal Slurry Pump is suitable for the transport of abrasive or corrosive slurries and is widely used in metallurgy, mining, petroleum, chemical, coal, electricity, transportation, river dredging, building materials and municipal engineering.

Model meaning

3 / 2 C - (R)

3------------Suction diameter(Inch)

2------------Discharge diameter(Inch)

C-----------Support type

-------- Pump Model

R-----------Natural Rubber

Specifications

| Pump Model | 3 / 2 C - |

| Allowable Max.Power | 30 kw |

| Capacity | 39.6- 86.4 m³/h |

| Head | 12 - 64 m |

| Speed | 1300 - 2700 r/min |

| Meax.Eff. | 55% |

| NPSH | 4 - 6 m |

| Impeller Diameter | 214 mm |

Centrifugal slurry pump working principle:

1. Before the pump works, the staff must first inject the liquid

used for conveying into the pipeline and the pump casing, and fill

the two;

2. When the slurry pump is started, the liquid in the impeller will be rotated by the blades of the impeller;

3. Under the action of centrifugal force, the liquid rotates forward and then flows out of the impeller;

4. During the process of flowing the liquid from the impeller inlet to the impeller outlet, the velocity energy and the pressure energy are increased due to the energy conversion, and the liquid flowing out from the impeller is discharged through the pump casing flow passage and then discharged from the discharge pipe;

5. At this time, the impeller inlet is formed by the discharge of water, and the liquid in the suction surface is pressed into the water inlet of the impeller under the action of atmospheric pressure;

6. The rotating impeller continuously draws in and drains water to form a continuous stream of water.

Typical Applications:

Ash Handling

Pulp and Paper

Abrasive Slurries

Coal Preparation

Mineral Processing

Aggregate Processing

Construction Design

Shaft Seal Module Design

Performance table

| MODEL | ALLOWABLE MATING MAX.POWER (KW) | MATERIAL | CLEAN WATER PERFORANCE | IMPELLER | ||||||||

| LINER | IMPELLER | Q Capacity | H Head | Speed | Max. Eff. | NPSH | VANES NO. | IMPELLER DIA | ||||

| m3/h | L/s | (m) | n(r/min) | (%) | (m) | (mm) | ||||||

| 1.5/1B- | 15 | M | M | 12.6-28.8 | 3.5-8 | 6-68 | 1200-3800 | 40 | 2--4 | 5 | 152 | |

| RU | RU | 10.8-25.2 | 3--7 | 7-52 | 1400-3400 | 30 | 3 | |||||

| 1.5/1C-HH | 30 | M | M | 16.2-34.2 | 4.5-9.5 | 25-92 | 1400-2200 | 20 | 2-5.5 | 5 | 330 | |

| 2/1.5B- | 15 | M | M | 32.4-72 | 9--20 | 6-58 | 1200-3200 | 45 | 3.5-8 | 5 | 184 | |

| RU | RU | 25.2-54 | 7--15 | 5.5--41 | 1000-2600 | 50 | 2.5-5 | 5 | 178 | |||

| 3/2C- | 30 | M | M | 39.6-86.4 | 11--24 | 12-64 | 1300-2700 | 55 | 4--6 | 5 | 214 | |

| RU | RU | 36-75.6 | 10--21 | 13-46 | 1300-2300 | 60 | 2--4 | 5 | 213 | |||

| 3/2D-HH | 60 | M | M | 68.4-136.8 | 19-38 | 25-87 | 850-1400 | 47 | 3-7.5 | 5 | 457 | |

| 4/3C- | 30 | M | M | 86.4-198 | 24-55 | 9-52 | 1000-2200 | 71 | 4--6 | 5 | 245 | |

| RU | RU | 79.2-180 | 22-50 | 5-34.5 | 800-1800 | 59 | 3--5 | |||||

| 4/3E-HH | 120 | M | M | 126-252 | 35-70 | 12-97 | 600-1400 | 50 | 2--5 | 5 | 508 | |

| 6/4D- | 60 | M | M | 162-360 | 45-100 | 12-56 | 800-1550 | 65 | 5--8 | 5 | 365 | |

| RU | RU | 144-324 | 40-90 | 12-45 | 800-1350 | 65 | 3--5 | 5 | 365 | |||

| 6/4S-HH | 560 | M | M | 324-720 | 90-200 | 30-118 | 600-1000 | 64 | 3-8 | 5 | 711 | |

| 8/6S-HH | 560 | M | M | 468-1008 | 130-280 | 20-94 | 500-1000 | 65 | 4-12 | 5 | 711 | |

| 8/6R- | 300 | M | M | 360-828 | 100-230 | 10-61 | 500-1140 | 72 | 2-9 | 5 | 510 | |

| RU | RU | 324-720 | 90-200 | 7-49 | 400-1000 | 65 | 5-10 | 5 | 510 | |||

| 10/8E-M | 120 | M | M | 666-1440 | 185-400 | 14-60 | 600-1100 | 73 | 4-10 | 5 | 549 | |

| 10/8ST- | 560 | M | M | 612-1368 | 170-380 | 11-61 | 400-850 | 71 | 4-10 | 5 | 686 | |

| RU | RU | 540-1118 | 150-330 | 12-50 | 400-750 | 75 | 4-12 | |||||

| 12/10ST- | 560 | M | M | 936-1980 | 260-550 | 7-68 | 300-800 | 82 | 6 | 5 | 762 | |

| RU | RU | 720-1620 | 200-450 | 7-45 | 300-650 | 80 | 2.5-7.5 | |||||

| 14/12ST- | 560 | M | M | 1260-2772 | 350-770 | 13-63 | 300-600 | 77 | 3-8 | 5 | 965 | |

| RU | RU | 1152-2520 | 320-700 | 13-44 | 300-500 | 79 | 3-10 | |||||

| 16/14TU- | 1200 | M | M | 1368-3060 | 380-850 | 11-63 | 250-550 | 79 | 4-10 | 5 | 1067 | |

| 20/18TU- | 1200 | M | M | 2520-5400 | 700-1500 | 13-57 | 200-400 | 85 | 5-10 | 5 | 1370 | |