ZHUZHOU JINTAI CEMENTED CARBIDE CO., LTD. |

|

OEM Cemented Carbide Rods Tungsten Metal Rod With High Wear Resistance

End mills,reamers and gravers are recommended. Excellent performance for high speed cutting. Suitable for cutting hardened steel, aluminum alloy and Titanium alloy. We provide custom-made, near-net-shape, premium insert blanks in cemented carbide - also known as Tungsten carbide or solid carbide.

Material composition:

1.Physical Properties:

A) Hardness greater than or equal to 92.8 HRA;

B) Density greater than or equal to 14.2 g/cm³;

C) TRS greater than or equal to 4200 N/mm²;

D) Free of ETA phase condition;

E) No contamination by other materials;

F) Porosity = A00 / B00 / C00 ;

G) Uniform and consistent grain size. No grain size can be larger

than specified.

H) Chromium carbide grain growth inhibitor only.

2.All the production, coatings are used in Germany, Switzerland,

processing equipment;

3.It's proposed cutting less than 60HRC;

Properties of cemented carbide grades recommended rods | |||||||

Grade | Chemical composition | Physical data | Grain size of WC(um) | ||||

| WC | Co | Others | Density(g/cm³) | Hardness(HV3) | TRS(MPa) |

|

YL10.1 | 93.5% | 6.0% | 0.5% | 14.88-15.04 | 1580±50 | 2500 | 1.2-1.7 |

YL10.2 | 89.5% | 10.0% | 0.5% | 14.4-14.55 | 1600±50 | 4000 | 0.8 |

YL10.5 | 89.7% | 9.5% | 0.8% | 14.4-14.55 | 1550±50 | 3800 | 0.7-0.9 |

YL50 | 85.0% | 15.0% |

| 13.86-14.10 | 1095 | 2060 | 0.4-0.6 |

YU06 | 93.0% | 6.0% | 1.0% | 14.7-14.8 | 2050 | 3000 | 0.2-0.4 |

YU08 | 91.0% | 8.0% | 1.0% | 14.56-14.65 | 1900 | 4000 | 0.2-0.4 |

YU09 | 89.8% | 9.0% | 1.2% | 14.36-14.50 | 1950 | 3900 | 0.2-0.4 |

YU12 | 87.0% | 12.0% | 1.0% | 14.05-14.15 | 1750 | 4000 | 0.2-0.4 |

YF06 | 93.5% | 6.0% | 0.5% | 14.86-14.96 | 1800 | 3800 | 0.4-0.6 |

YF08 | 91.4% | 8.0% | 0.6% | 14.55-14.65 | 1800 | 3900 | 0.4-0.6 |

YG6X | 93.5% | 6.0% | 0.5% | 14.8-15.10 | 91 | 1560 | 1.0 |

YG8 | 92.0% | 8.0% |

| 14.6-14.9 | 89.5 | 1840 | 1.2-1.6 |

~ Customized Tungsten carbide products are available!

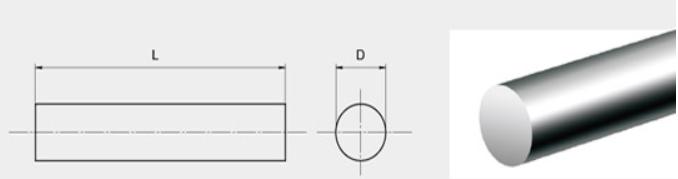

| Type | D(mm) | Tol. Of diameter(mm) | L(mm) | Tol. Of diameter(mm) |

| ¢1.0*330 | 1.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢2.0*330 | 2.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢3.0*330 | 3.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢4.0*330 | 4.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢5.0*330 | 5.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢6.0*330 | 6.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢7.0*330 | 7.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢8.0*330 | 8.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢9.0*330 | 9.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢10.0*330 | 10.0 | +0.2~+0.5 | 330 | 0~+5.0 |

| ¢11.0*330 | 11.0 | +0.2~+0.5 | 330 | 0~+5.0 |

| ¢12.0*330 | 12.0 | +0.2~+0.5 | 330 | 0~+5.0 |

| ¢13.0*330 | 13.0 | +0.2~+0.5 | 330 | 0~+5.0 |

| ¢14.0*330 | 14.0 | +0.2~+0.5 | 330 | 0~+5.0 |

| ¢15.0*330 | 15.0 | +0.2~+0.6 | 330 | 0~+5.0 |

| ¢16.0*330 | 16.0 | +0.2~+0.6 | 330 | 0~+5.0 |

| ¢17.0*330 | 17.0 | +0.2~+0.6 | 330 | 0~+5.0 |

| ¢18.0*330 | 18.0 | +0.2~+0.6 | 330 | 0~+5.0 |

| ¢19.0*330 | 19.0 | +0.2~+0.6 | 330 | 0~+5.0 |

| ¢20.0*330 | 20.0 | +0.2~+0.7 | 330 | 0~+5.0 |

| ¢21.0*330 | 21.0 | +0.2~+0.7 | 330 | 0~+5.0 |

| ¢22.0*330 | 22.0 | +0.2~+0.7 | 330 | 0~+5.0 |

| ¢23.0*330 | 23.0 | +0.2~+0.7 | 330 | 0~+5.0 |

| ¢24.0*330 | 24.0 | +0.2~+0.7 | 330 | 0~+5.0 |

| ¢25.0*330 | 25.0 | +0.2~+0.7 | 330 | 0~+5.0 |

| ¢26.0*330 | 26.0 | +0.2~+0.8 | 330 | 0~+5.0 |

| ¢27.0*330 | 27.0 | +0.2~+0.8 | 330 | 0~+5.0 |

| ¢28.0*330 | 28.0 | +0.2~+0.8 | 330 | 0~+5.0 |

| ¢29.0*330 | 29.0 | +0.2~+0.8 | 330 | 0~+5.0 |

| ¢30.0*330 | 30.0 | +0.2~+0.8 | 330 | 0~+5.0 |