SHANGHAI E&V IMPORT AND EXPORT CO.,LTD |

|

Verified Suppliers

|

|

Low production costs copper alloy rod rolling mill / Copper Rolling

Mill

I. Detail information of the machine

The unit is used for copper rod cold rolling. Invented,designed and produced by our own company ,the rolling machine having many patents for invention at home and abroad ,used by many company on global,high quality

II. Advantage

1.seperate motor

2.high quality

3.good reponds

4.roll diffient material

5.roll diffient size

6.Perfect service,timely customer response

7.reduce rolling manual consumption

III.Main Data

| No. | item | Parameter |

| 1 | Model: | Copper rod cold rolling mill, copper alloy cold rolling mill. Other metal rod cold rolling mill, other alloy cold rolling mill,copper / aluminum continuous casting and rolling etc. |

| 2 | Input dia | Ф55mm,Ф35mm,Ф25mm,Ф20mm,Ф17mm,Ф16mm,Ф14.4mm,Ф12.5mm,Ф8mm etc. |

| 3 | Output dia | Ф20mm,Ф18mm,Ф17mm,Ф8mm,Ф6mm,Ф5mm,Ф4mm,Ф3 mm etc. |

| 4 | Outlet rod out of roundness | No more than 0.2mm after rolling, or more accurate |

| 5 | Rolling pass | 2-16 or as each customer’s requirements |

| 6 | Rolling speed | Max 3M/s for continuous rolling, Max 5M/s for discontinuous rolling. |

| 7 | Pass schedule | ellipse-round hole type system or triangular -round type system |

| 8 | total extend compression ratio | 2-10, or as each customer’s requirements |

| 9 | each pass compression ratio | 1.15~1.4(hole type can change) |

| 10 | Total power | 100kw~500kw |

| 11 | Running mode | Each frame separate transmission speed controlled by frequency or AC servo |

| 12 | Operation mode | PLC control, touch screen display,can improve to DCS control or networking |

| 13 | type | 2 high horizontal- vertical or 3 high positive triangle-inverted triangle |

| 14 | nominal roller dia | Ф200mm(double-groove/multi-groove),Ф248mm(double-groove/multi-groove),Ф264mm,Ф300mm,Ф370mm,Ф400mm etc. |

| 15 | No. of frame | 2-16 or more |

| 16 | Main motor | 11kw-110kw AC frequency motor or AV servo motor for each |

| 17 | roller material | other imported material etc. |

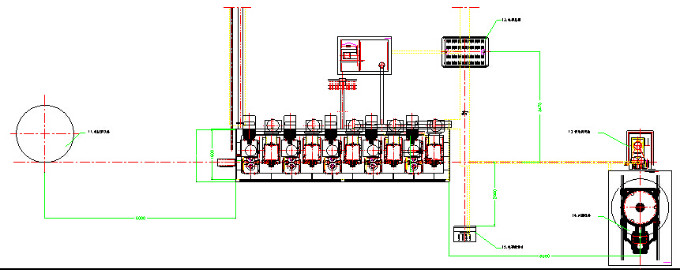

| 18 | rolling mill size | a complete production line: length 18m *width 6 m*height 2.5m Main machine : length 7.6m*width 2.3m *height 2m |

| 19 | height of center | height from the ground 1230mm |

IV.Main component

1. Rolling mill base 2. 2-roller motive power frame(including reducer, Inverter motor) 3. Pay-off frame 4. coiling take-up system 5. Lubrication system 6. Emulsion system 7. Electronic control system 8.straightening device

V.Technical process

Check the device→Touch screen enters to the normal working

screen→Open the oil pump

↓

Open the emulsion pump

↓

The increase the speed and turn into ← Rolling the copper rod ←

Start the rolling mill

nomol production

VI.Why you should choose us

1.Our machines have the first-class quality in China.

2.The delivery time is generally about 30~100 days.

3.We have independent right to do foreign trade.

4.We always trade with foreign countries on the basis of

credit,equality and mutual benefit.

Our company is engaged in manufacturing metal casting machines,wire drawing

machines,melting furnaces and extrusion machines. We are a large

scale group with new technology, update skill, latest device and

combining research, production and sales

55mm, 35mm, 25mm, 20mm, 17mm, 16mm, 14.4mm, 12.5mm, 8mm

20mm,18mm, 17mm, 8mm, 6mm, 5mm, 4mm, 3mm