Weikeda Packaging Technology (Kunshan) Co.,Ltd |

|

The power roller is a common conveying device. The common one is the conveying carton, which can transport the finished carton to a specified position from a long distance. It is generally used for the connection between various packaging equipment and the long-distance transmission of finished products. The power roller produced by the company. The conveyor is made of reinforced aluminum profile bracket.

The roller is made of reinforced metal roller, which is wear-resistant and stable. The side is made of aluminum and nylon rails, which is firm and reliable.

The non-powered roller is to transport the object under the action of external force and gravity, so that it can move in a certain direction to complete the conveying function, and its structure

The design is modular, simple and reliable, and easy to maintain.

It can greatly reduce the strength of work such as handling,

loading and unloading, and improve work efficiency. It can be used

alone or in any combination. It can be easily handled regardless of

the weight or size of the items.

Product description:

1.This machine is designed for square or flat bottles packing.

2.Considering the special features of flat bottles,we add extra

servo mechanism on the separation line conveying products into the

whole conveyor line.

3.This machine specialize in making products ordered and avoid the

phenomenon of bottles plugging.

Other features:

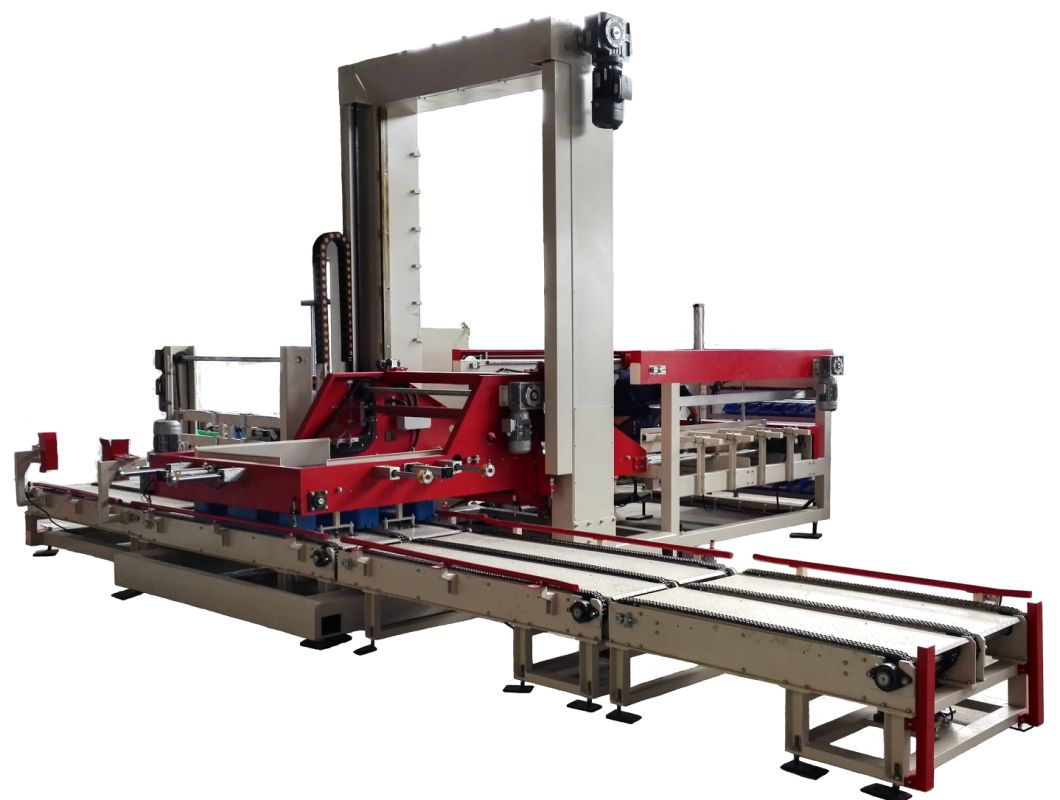

1. This machine is the longmen posture low stacking machine, the entire layer stacking.

2. Touch screen operation is adopted to accomplish the man-machine dialogue, simple easy to operate.

Production speed can be shown, the cause of the problem and position.

3. The order of the carton of the PLC programmable number of stacking, pallet supply and discharge can be programmed to control.

4. The security, the cover is equipped with electric induction device, cover when the door opened, the machine stop working, and to protect personnel.

5. Stacking is stable, efficient and can greatly save manpower.

6. Carton supply system adopts brake motor to control, ensure

delivery according to the predefined position the cartons.

7. Pallet database is big, can accommodate 8-10 empty pallet, which

can realize automatic supply pallet.

8. Applicable product type: cartons, film bags, cans and so on a

flat surface of the product

| Power supply | AC380 v, 50HZ, 9KW |

| Air pressure | 500nl/min |

| Machine size | L7900*W5150*H3750mm |

| Pallet size | 1200*1200mm |

| Pallet speed | 4-5beats/min |

| PLC | Mitsubishi |

| Optoelectronic switch | P+F |

| Electrical magnetic valve | AIRTAC |

| Pneumatic element | AIRTAC /SMC/ FESTO |

Application

About us:

Weikeda Packaging technology (kunshan) Co.,Ltd is specializing in the production of automated packaging equipment manufacturers, focusing on the automated case packaging machinery about the overall planning, design, manufacture and maintenance.It is located in Spanish Industrial Park Qiandeng Town, Kunshan city, Jiangsu province. Adjacent to Shanghai traffic arteries, the geographical position is superior.

The main products: Case filling machine, Wrap-around case packing machine, Palletizer, Case Erector, Case Sealer and automatic packaging conveyor system products. We introduces the domestic and foreign new technology, accumulated many years of development and manufacturing experience, uphold integrity, professional, pragmatic and innovative spirit, according to the needs of different users and different industries, to provide more intelligent, more stable, more economic and reasonable planning, to provide you with high quality products and perfect comprehensive after-sales service.

Warmly welcome the domestic and foreign customers to visit and

field trips. V-PAK will be your best partner and most reliable

friend.

Our office:

Our factory:

After sale service:

1. Installation

After equipment reached the workshop of customer, We will arrange

seasoned technician for equipment installation, debug and test

production and at the same time make the equipment reach the rated

producing capacity of the line. Time for installation and debug is

around 15-25 days.

2. Training

Our company offers technology training to customer. The content of

training covers structure and maintenance of equipment, control and

operation of equipment. Training will be arranged in the workshop

of customer. Seasoned technician will guide and establish training

outline. After training, the technician of buyer could master the

operation and maintenance, could adjust the process and treat

different failures.

3. Quality guarantee

We promise that our goods are all new. They're made of suitable

material, adopt new design. The quality, specification and function

all meet the demand of contract. We promise that the products of

this line could last for one year without adding any aseptic

Why us:

- Original manufacturer with 10-year professional experience.

- Customized equipment according to customer' requirements, high

quality with competitive price.

- Abundant export experience: our products have been exported to

Indonesia, Malaysia, Vietnam, Singapore, etc .

- Superior after-sale service: Engineers available to

service machinery overseas.

FAQ:

1. Are you a factory or trading company?

We are a professional packaging machine manufacturing factory

that set up for 10 years. We always pay attention to the

development of the industry. We can give a discount according

to the quantity of machine you purchase.

2. How long can I get feedback after inquiry?

We will reply you within 10 hours in working day.

3. Where is your factory located? How can I visit there?

Our factory is located in Qian Deng Town, Kun Shan City, Jiangsu

Province, China.

We will provide pick-up service if you want to visit our company.

You can choose the destination of Pudong airport or Hongqiao

airport. Hongqiao airport will be much more closer to our company.

4. Delivery time

Machines & molds order takes 55 work days after

pre-payment received.

5. What is the package? Is it suitable for shipment?

Machines will be packed by the standard wooden case or PE film

wrapping.

It is suitable for shipment.

6. Payment term

30% by T/T as down payment, balance 70% by T/T or L/C before

delivery.

7. Can I trust you?

Sure, we are the manufacturer certified by SGS and CE,

8. How long is the warranty for machines?

Machines warranty is 12 months from installation

& commissioning.

9. How' s your after-sale service?

After sales support and service is very important to customers and

we will respond to you soon if parts are required they would be

sent to you by international courier within 48 hours.

10. Can you engineer come to our place to help with machine

installation & commission?

Yes, our engineers are available to travel to your place. Round

flight tickets & accommodation will be at your cost. And

the cost for our labor is one hundred USD per person per day.