Guangzhou HS Machinery Co., Ltd. |

|

Verified Suppliers

|

|

Folding Gluer Machine 1630 Four Color Printing Slotting Die Cutting Machine

Model:1600x3000

Product description

This machine adopts vacuum adsorption help carrying paper ,PLC touch screen control system.Man-machine conversation,The main machine with frequency conversion motor.360 phase adjustment controlled by microcomputer,The speed of glue rolls automatically giving.At the same time,it set up the computer program and glue case reparied equipment,feed accruracy less than 0.5mm,it has many good characteristics such as slicing high precision,high speed,operating easy and so on.

1. Computerized control,automatic adjustment.

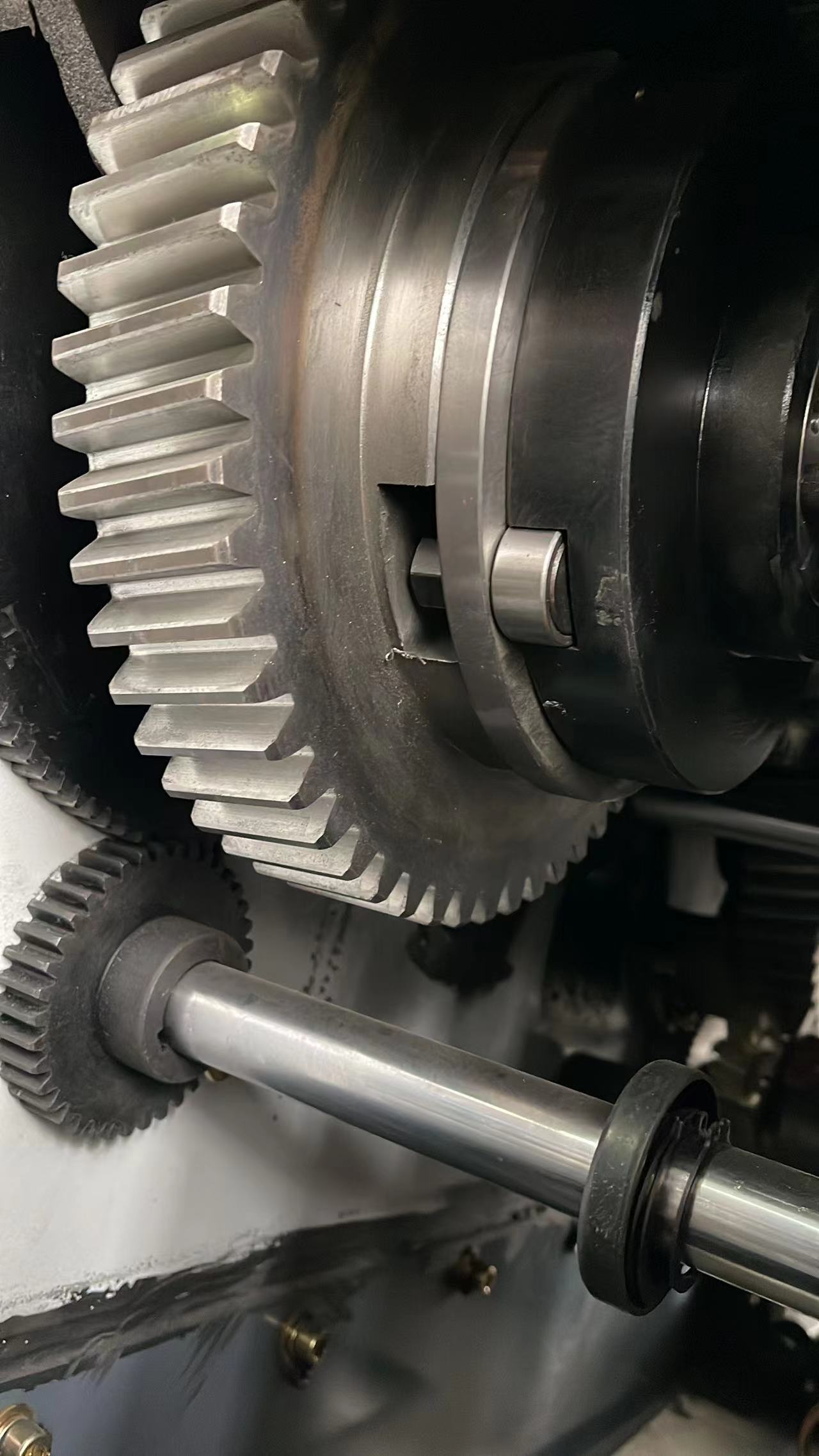

2. Precise planet-geared phase adjustment device.

3. Anvil roll can be motorized adjust in circumferential &

traversal;direction to prolong its usage life.

4. Quick change over rubber anvil,good wear-ability.

5. Speed difference compensation system make line speed be

synchronization,it can ensure die-cutting precise.

Standard equipments:

A. Independent Lead Edge Feeder;

B. printers

C. motorized slotter

D. Rotary Die Cutter with auto trimming device;

E. Auto Stacker

| Model | 1600x3000 |

| Machine Speed(m/min) | 200 |

| Machine Max.speed (pcs/min) | 150 |

| Machine Max.feeder Size(mm) | 1600x3000 |

| Machine min.feeder Size(mm) | 450x760 |

| Machine Max. printer size (mm) | 1500x2900 |

| thick of printer Plate(mm) | 7.2 |

| Max. slotter Dep (mm) | 560 |

| Max. Thickness of Sheet(mm) | 15 |

Machine size (LxWxH)

| 19852x6670x2700 |

Independent Lead Edge Feeder

| Item | Descriptions |

1. Lead Edge Feeding system | 1.Vacuum transfer lead edge feeder. 2.Back buffle and side buffle are all motorized adjustment. 3.Feeder sliding block is of aluminum structure to guarantee a more stable working with less vibration. 4.Sheet counting in touch screen. 5.Skip feeding for bigger sheet. 7.Pneumatic lift device with end chain-lock switch for convenient operation. |

| 2. Machine open/cloe | 1.Button auto control for machine open/close with alarm device to safeguard operators. 2.Pneumatic locking system, whole machine locked on fixed track by feeder main pneumatic cylinder. |

| 3. Feeding roll | 1. Endurable rubber-coated feeding roll to add use life. |

| 4. Zero return device | 1.Computer adopts zero return device with memory function to guarantee the same adjustment standard, auto adjustment of correct position to reduce the waste of boards. |

Features of printing units

| Item | Features |

1. Printing cylinder | 1.Printing phase adjustment adopts satellite gear wheel structure, PLC control, digital display, 360 degree circumferential adjustment, stable start, correction positioning. 2.Grinded printing cylinder with harm chrome, with cross line and center line, for convenient cliché fixation and sticking, correct positioning and quick cliché registration. 3.Balance treatment, stable running, for high speed running. 4. Quick and convenient fixing system for the printing cliché. 5. Quick cliché change system to speed up the order renewal time. 6.Zero position device for printing cylinder for quick positioning of cliché change and correction, for repeated carton specification change. Foot stepping device for cliché fixation and dismantling. Phase micro adjustment. 7. Printing cylinder left/right movement distance: 10mm. 8. Diameter of printing cylinder: ø524mm,ø304mm(with cliché thickness) |

| 2. Impression cylinder(ø156mm) | 2.Impression cylinder gap adopts adjustable offset ring, with close structure, precise positioning, adjustment scope: 0-12mm. |

| 3. Feeding roll | 1.Up feeding roll: grinded and hard chromed. 2.Lower feeding roll: grinded, sand-frosted and hard-chromed. 3.Lower feeding shaft gap adjustment adopts offset ring with close structure, correction positioning, adjustable at 0-12mm. |

4. Rubber roll

| 2.Steel pipe rubber-coated durable for longlife. 3.Super clutch and auto empty run device against ink dry. 4.Midheight grinding for high LPI big space printing. 5. Rubber roll open/close adopts worm gearbox manual adjustment, with worm gearbox for gap adjustment with scale indication. |

| 5. Anilox roll | 1. Seamless steel pipe for precise processing, balance treatment for stable running, grinding and hard chromed. 2.Longlife running, anti-grinding and erosion, ideal ink transferring and controlling performance. 3.Pneumatic anilox auto elevation device and empty run device. 4.Speed difference between anilox roll and rubber roll for ink doctoring effect to increase printing quality. |

| 6. Inking system | 1.Single-way pneumatic membrane auto circulating pump. 2. Ink filtering net to filter the dirt for nice printing result. 3.Encased ink chamber. |

| 7. Phase adjustment structure | 1.Satelite gear wheel design. 2.Motorized circumferential adjustment, digital display, 360 degree run or stop adjustment. 3.PLC control, quick reach, convenient for cliché adjustment. 4. Manual gap Pressure adjustment for all units. |

| 8. Printing cylinder fixed device | 1.Electromagnetic braking structure. 2.When machine unit separates or adjust phase, braking system to control the running of machine units to keep original gear positioning point. |

| 9. Printing cylinder fixed device | 1.Electromagnetic braking structure. 2.When machine unit separates or adjust phase, braking system to control the running of machine units to keep original gear positioning point. |

Features of slotting unit

| Item | Features |

| 1. Slotting phase adjustment | 1.High precision inverter to adjust the speed, 360 degree adjustment, quick time. 2.Phase zero positioning device to guarantee slotting position sameness. |

| 2. Creasing wheel | 1.Manual/motorized adjustment of creasing wheel and slotting knife head position through precise screw pole. 2.Creasing wheel down shaft, slotting knife down shaft adopt offset ring, close structure for precise positioning. |

| 3. Slitting and slotting knife head | 1.Blade thickness:7mm. Imported high quality alloyed moon-shaped saw slotting blades, high hardness, high endurability, high grindability. 2.Grinded and hard-chromed slotting shaft for stable running. 3.Manual adjustment of slotting knife head, creasing wheel and slitting knife head. 4.Auto detection device of slotting shaft circumferential position, auto record of the position and guarantee the position auto return. 5. Pre-creaser fixed before slotter. 6. Front knife and back knife seated on one shaft. |

Features for Rotary Die Cutting Unit

| Item | Features |

1. Die cutting mould cylinder( Down cylinder) | 1.Die cutting cylinder is made by high quality steel, fine grinding, hard chromed. 2. Balance treatment to increase stable running. 3.Die cutting mould fixation screws M10, hole distance at 100mm at transversal direction and 18 equal units at circumferential direction. 4.Die cutting wooden mould thickness 13-15mm(five ply), 16-18mm(three ply). |

2. Rubber mat cylinder(Down cylinder) | 1.Mat cylinder uses high quality steel, grinding, hard chromed. 2.Balance treatment for stable running. 3.Rubber mat thickness 8mm, width 250mm. 4.Rubber mat cylinder mechanical rotary direction change 40mm distance movement structure, movement speed same as the machine running speed. 5.Manual adjustment of die cutting mould gap, adjustment range: 0-16mm. |

| 3. Phase adjustment device | 1.Satellite gearwheel structure 2.PLC and encoder control of die cutting phase adjustment for start and stop adjustment. |

Superior Quality and Maximum Efficiency: the Advantages of Printing Slotter Die Cutters:

In today's fast-paced business environment, it is important for companies to optimize their production processes to maximize efficiency and profitability. One of the key tools for achieving this is the slotter-die cutter, a printing machine that cuts, folds, and scores paper and cardboard to precision shapes and sizes. The advantages of using slotter-die cutters for printing operations are numerous and significant, including superior quality, maximum efficiency, and the ability to perform a wide range of functions.

One of the most fundamental advantages of slotter-die cutters is their ability to produce high-quality printed materials. Because they are designed to cut and print materials with a high level of accuracy and precision, slotter-die cutters are ideal for producing a variety of high-quality products, including packaging boxes, cartons, labels, and display stands. The machines allow for intricate, precise cuts that produce smooth and clean edges, ensuring a professional, polished finish on all printed materials. They also offer a range of customization options, including the ability to print on a variety of materials, from thin film to corrugated cardboard, and to add unique shapes, colours, and designs to any print job. With the ability to produce high-quality, highly customized printed materials, slotter-die cutters are an indispensable tool for any printing operation that wants to stand out in a crowded market.

In addition to high-quality printing capabilities, slotter-die cutters also offer maximum efficiency in the printing process. These machines are highly automated and can process large quantities of materials at a high speed, making them ideal for high-volume printing jobs. They also minimize waste by using only the exact amount of material needed for each print job, which reduces costs and helps the environment. Slotter-die cutters are designed with a range of advanced features that improve efficiency, including automatic feeding systems, advanced cutting and folding technology, and integrated software that streamlines the printing process. With these features, printing operators can produce large quantities of high-quality materials quickly and effortlessly, helping to reduce lead times and increase output.

Another advantage of slotter-die cutters is their ability to perform a wide range of functions, making them a versatile tool for any printing operation. In addition to cutting and folding cardboard and paper, these machines can also be used to create customized packaging, display stands, and promotional materials. They can print on a variety of materials, including paper, plastic, and metal, and can produce a wide range of shapes and sizes. Slotter-die cutters are also widely used in the printing of labels, stickers, and decals for a range of products, from consumer goods to industrial components. With their broad range of capabilities, slotter-die cutters are an invaluable addition to any printing operation that requires flexibility and versatility in their printing processes.

Beyond the immediate benefits of superior quality, maximum efficiency, and flexible functionality, slotter-die cutters also offer a range of long-term advantages for businesses. First and foremost, they help to increase customer satisfaction by producing high-quality materials that meet or exceed customer expectations. This can lead to increased customer loyalty, repeat business, and positive word-of-mouth recommendations. Furthermore, slotter-die cutters can help to reduce costs over the long term. By minimizing waste, reducing lead times, and increasing output, they can help printing operations to improve their bottom line and remain competitive in a rapidly changing marketplace. Finally, slotter-die cutters can help printing operations to stay ahead of the curve in terms of technological innovation. As the printing industry evolves and new technologies emerge, slotter-die cutters are well-positioned to integrate these technologies and stay at the forefront of the industry.

In conclusion, slotter-die cutters offer a range of advantages for printing operations that are looking to optimize their production processes and maximize efficiency and profitability. From their superior quality and maximum efficiency to their flexibility and versatility, slotter-die cutters are an indispensable tool for any printing operation that wants to produce high-quality, customized materials quickly and efficiently. For printing operators looking to stay ahead of the curve and remain competitive in a crowded marketplace, slotter-die cutters are a must-have investment.