Guangzhou HS Machinery Co., Ltd. |

|

Verified Suppliers

|

|

Corrugated Box Printing Machine High Speed 1628 Three Color Printer Slotter Rotary Die Cutter

Model:1600x2800

1.The whole machine is adopted international famous brand appliances "Schneider" .The quality is stable and reliable.

2.The machine shaft, roller are adopted high quality steel, grinding processing, high precision computer dynamic balancing correction and surface hard chromium plating.

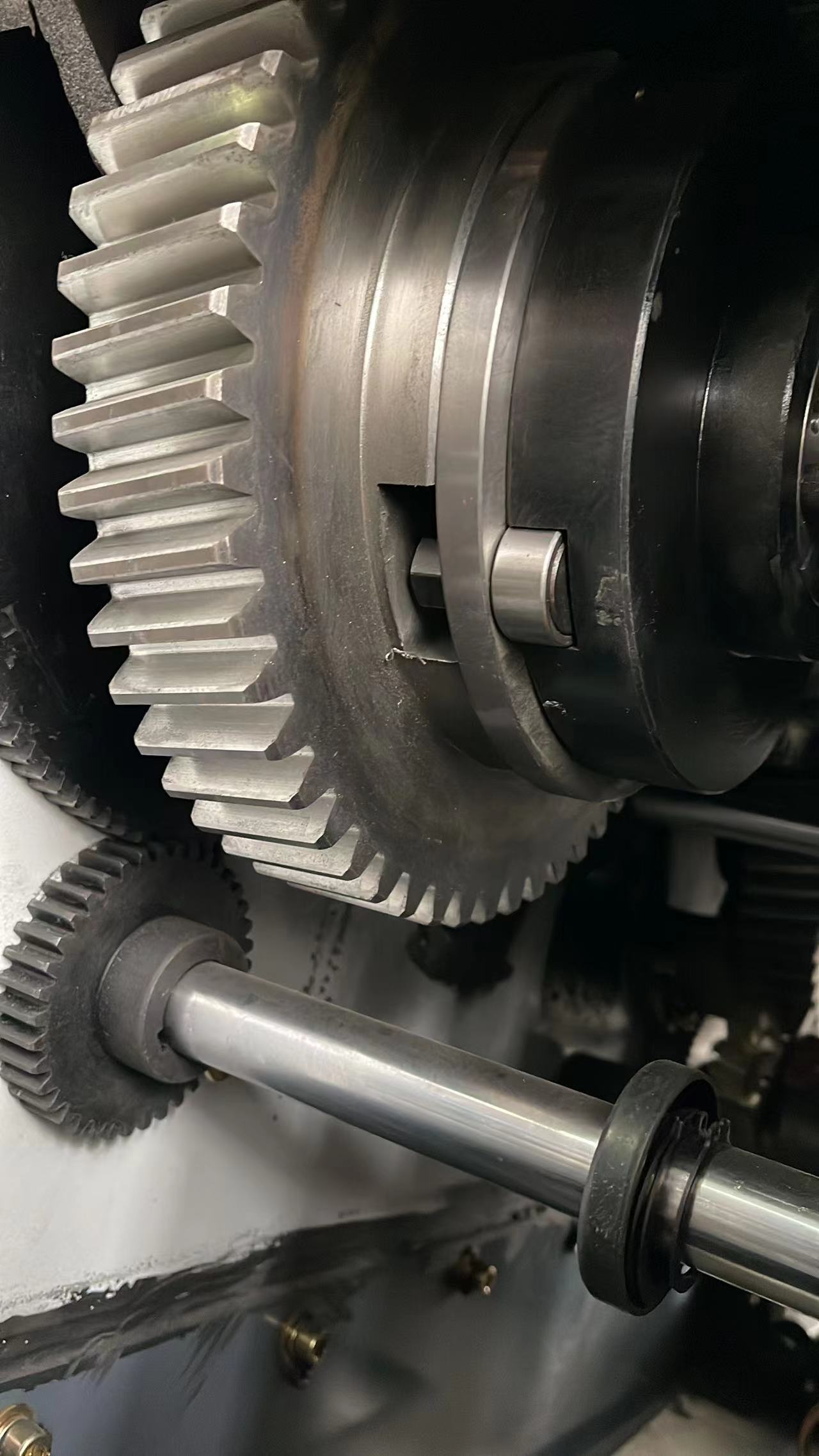

3.The engine drive gear is adopted 40Cr, the shaving machining nitrogen treatment, tinted with high precision.

4.Machine transmission parts (shaft, gear joint) is adopted free key connection (LOCK -ALX),clears the connection gap.lt is 5.suitable for long-term high speed running with high torque.

6. The engine lubrication system is adopted automatic spray type lubrication, equipped with auto oil level balance system.

7. It adopts Working gap adjustment, self-locking type worm wheel and worm gear device , quick performance and convenient adjustment.

8.The main motor is adopted frequency conversion control.Ilt makes start, running more steadily and saves more energy.

9. Chuan-ink system that uses high-precision network transmission ink roller and rubber roller, and the other and independent motor drive, beyond the clutch to ensure the shutdown stop ink, the ink pneumatic diaphragm pumps, pneumatic lift version.

10. cut-off machine, automatic locking,power walking,clutch protection

11. Transmission gear, forged 40 cr quenched and tempered, grinding tooth nitriding processing, oil pump spray lubrication,

12. prolong the service life of the gear, ensure long-term printing color accuracy..Front the good luck send a paper way.

Standard equipments:

A. Independent Lead Edge Feeder;

B. printers

C. motorized slotter

D. Rotary Die Cutter with auto trimming device;

E. Auto Stacker

| Model | 1600x2800 |

| Machine Speed(m/min) | 200 |

| Machine Max.speed (pcs/min) | 150 |

| Machine Max.feeder Size(mm) | 1600x2800 |

| Machine min.feeder Size(mm) | 450x760 |

| Machine Max. printer size (mm) | 1500x2700 |

| thick of printer Plate(mm) | 7.2 |

| Max. slotter Dep (mm) | 560 |

| Max. Thickness of Sheet(mm) | 15 |

Machine size (LxWxH)

| 19852x6670x2700 |

Independent Lead Edge Feeder

| Item | Descriptions |

1. Lead Edge Feeding system | 1.Vacuum transfer lead edge feeder. 2.Back buffle and side buffle are all motorized adjustment. 3.Feeder sliding block is of aluminum structure to guarantee a more stable working with less vibration. 4.Sheet counting in touch screen. 5.Skip feeding for bigger sheet. 7.Pneumatic lift device with end chain-lock switch for convenient operation. |

| 2. Machine open/cloe | 1.Button auto control for machine open/close with alarm device to safeguard operators. 2.Pneumatic locking system, whole machine locked on fixed track by feeder main pneumatic cylinder. |

| 3. Feeding roll | 1. Endurable rubber-coated feeding roll to add use life. |

| 4. Zero return device | 1.Computer adopts zero return device with memory function to guarantee the same adjustment standard, auto adjustment of correct position to reduce the waste of boards. |

Features of printing units

| Item | Features |

1. Printing cylinder | 1.Printing phase adjustment adopts satellite gear wheel structure, PLC control, digital display, 360 degree circumferential adjustment, stable start, correction positioning. 2.Grinded printing cylinder with harm chrome, with cross line and center line, for convenient cliché fixation and sticking, correct positioning and quick cliché registration. 3.Balance treatment, stable running, for high speed running. 4. Quick and convenient fixing system for the printing cliché. 5. Quick cliché change system to speed up the order renewal time. 6.Zero position device for printing cylinder for quick positioning of cliché change and correction, for repeated carton specification change. Foot stepping device for cliché fixation and dismantling. Phase micro adjustment. 7. Printing cylinder left/right movement distance: 10mm. 8. Diameter of printing cylinder: ø524mm,ø304mm(with cliché thickness) |

| 2. Impression cylinder(ø156mm) | 2.Impression cylinder gap adopts adjustable offset ring, with close structure, precise positioning, adjustment scope: 0-12mm. |

| 3. Feeding roll | 1.Up feeding roll: grinded and hard chromed. 2.Lower feeding roll: grinded, sand-frosted and hard-chromed. 3.Lower feeding shaft gap adjustment adopts offset ring with close structure, correction positioning, adjustable at 0-12mm. |

4. Rubber roll

| 2.Steel pipe rubber-coated durable for longlife. 3.Super clutch and auto empty run device against ink dry. 4.Midheight grinding for high LPI big space printing. 5. Rubber roll open/close adopts worm gearbox manual adjustment, with worm gearbox for gap adjustment with scale indication. |

| 5. Anilox roll | 1. Seamless steel pipe for precise processing, balance treatment for stable running, grinding and hard chromed. 2.Longlife running, anti-grinding and erosion, ideal ink transferring and controlling performance. 3.Pneumatic anilox auto elevation device and empty run device. 4.Speed difference between anilox roll and rubber roll for ink doctoring effect to increase printing quality. |

| 6. Inking system | 1.Single-way pneumatic membrane auto circulating pump. 2. Ink filtering net to filter the dirt for nice printing result. 3.Encased ink chamber. |

| 7. Phase adjustment structure | 1.Satelite gear wheel design. 2.Motorized circumferential adjustment, digital display, 360 degree run or stop adjustment. 3.PLC control, quick reach, convenient for cliché adjustment. 4. Manual gap Pressure adjustment for all units. |

| 8. Printing cylinder fixed device | 1.Electromagnetic braking structure. 2.When machine unit separates or adjust phase, braking system to control the running of machine units to keep original gear positioning point. |

| 9. Printing cylinder fixed device | 1.Electromagnetic braking structure. 2.When machine unit separates or adjust phase, braking system to control the running of machine units to keep original gear positioning point. |

Features of slotting unit

| Item | Features |

| 1. Slotting phase adjustment | 1.High precision inverter to adjust the speed, 360 degree adjustment, quick time. 2.Phase zero positioning device to guarantee slotting position sameness. |

| 2. Creasing wheel | 1.Manual/motorized adjustment of creasing wheel and slotting knife head position through precise screw pole. 2.Creasing wheel down shaft, slotting knife down shaft adopt offset ring, close structure for precise positioning. |

| 3. Slitting and slotting knife head | 1.Blade thickness:7mm. Imported high quality alloyed moon-shaped saw slotting blades, high hardness, high endurability, high grindability. 2.Grinded and hard-chromed slotting shaft for stable running. 3.Manual adjustment of slotting knife head, creasing wheel and slitting knife head. 4.Auto detection device of slotting shaft circumferential position, auto record of the position and guarantee the position auto return. 5. Pre-creaser fixed before slotter. 6. Front knife and back knife seated on one shaft. |

Features for Rotary Die Cutting Unit

| Item | Features |

1. Die cutting mould cylinder( Down cylinder) | 1.Die cutting cylinder is made by high quality steel, fine grinding, hard chromed. 2. Balance treatment to increase stable running. 3.Die cutting mould fixation screws M10, hole distance at 100mm at transversal direction and 18 equal units at circumferential direction. 4.Die cutting wooden mould thickness 13-15mm(five ply), 16-18mm(three ply). |

2. Rubber mat cylinder(Down cylinder) | 1.Mat cylinder uses high quality steel, grinding, hard chromed. 2.Balance treatment for stable running. 3.Rubber mat thickness 8mm, width 250mm. 4.Rubber mat cylinder mechanical rotary direction change 40mm distance movement structure, movement speed same as the machine running speed. 5.Manual adjustment of die cutting mould gap, adjustment range: 0-16mm. |

| 3. Phase adjustment device | 1.Satellite gearwheel structure 2.PLC and encoder control of die cutting phase adjustment for start and stop adjustment. |

Introduction

The 1628 Three Color Printer Slotter Rotary Die-Cutter is a state-of-the-art printing machine that is designed to provide high-quality prints efficiently and effortlessly. This printer is designed with the latest technology to ensure that every print job is of the highest standard, making it an ideal choice for businesses looking to showcase their brand in a professional and sophisticated way.

If you are planning to invest in a printing machine that will meet all your printing needs, then the 1628 Three Color Printer Slotter Rotary Die-Cutter is the perfect choice. In this article, we will explore the features of the 1628 Three Color Printer Slotter Rotary Die-Cutter and how it can help you achieve the perfect results for all your print jobs.

Speed and Efficiency:

The 1628 Three Color Printer Slotter Rotary Die-Cutter is designed for speed and efficiency. This machine is equipped with a high-speed printing system that can print up to 250 sheets per minute. This means that you can print a large volume of sheets in a short period, making it perfect for businesses that need to print large quantities of materials. Additionally, it is efficient in terms of ink consumption, making it both cost-effective and eco-friendly.