Rino Packaging Machinery Co., Ltd |

|

4 Color Carton Box Flexo Printing Machine Printer Slotter Die Cutter Machine For Corrugated Board

Box Flexo Printing Machine Introduction

The front of the main machine is equipped with paper output monitoring equipment, and the situation of the paper output department is observed at any time when starting and stopping machine to ensure the safety of the operator who start and adjust the machine. Each part is electrically separated and combined, pneumatic locking, pneumatic lifting, automatic ink distribution, and ink shortage alarm system to ensure the normal operation of the whole machine, fine printing patterns and accurate color registration. All drive shafts of the whole machine are treated with dynamic and static balance, and the gears are special processed , all are carburized and grounded, the overall hardness is HRC52-58, and the accuracy is level 6. All gear lubrication adopts spray-type circulating lubrication, equipped with circulating oil display window, to observe the oiling situation at any time.

Parameter of Carton Flexo Printing Machine

| Model | HP-LM1200 |

| Width | 2800mm |

| Maximum speed(pcs/min) | 200 |

| Wallboard thickness(mm) | 60 |

| Gear thickness(mm) | 60 |

| Maximum paper size(mm) | 1200 X 2600 |

| Minimum paper size(mm) | 350 X 650 |

| Skip paper feeding(mm) | 1450 X 2600 |

| Maximum printing size(mm) | 1200 X 2500 |

| Standard printing plate thickness(mm) | 3.2---7.2 |

| Cardboard thickness(mm) | 3---12 |

| Precision(mm) | Tinted accuracy ±0.5,die cutting accuracy ±1.5 |

| Power (kw) | 38 |

| Total power(kw) | 45 |

Main units

|

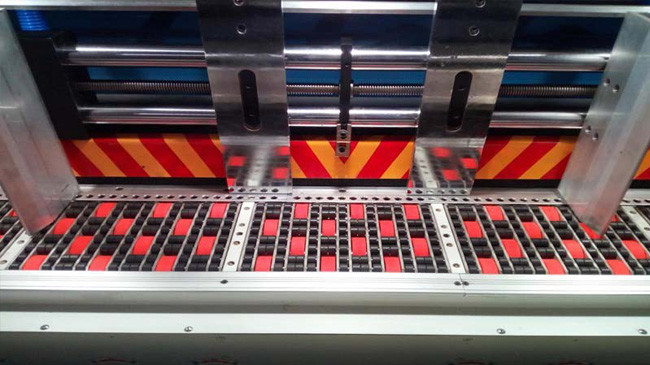

Paper feeding unit

|

|

Printing unit

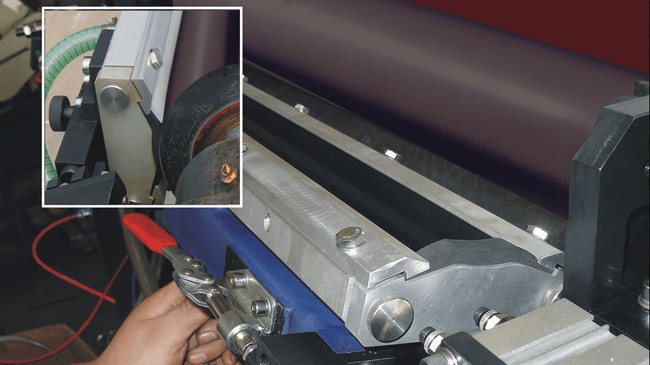

Doctor blade system (optional additional price) 1. The innovative chamber fluid dynamics and ink sealing design of the enclosed double squeegee system have a good ink delivery effect and can save ink. The air pressure or cylinder is adjusted and locked, and the doctor blade wear is automatically compensated, so that the anilox roller and the doctor blade can fit better to obtain the best scraping effect. The Teflon anti-corrosion and anti-sticking coating in the inner chamber makes the ink transfer and cleaning easier. The all-round installation design can replace any old-fashioned rubber roller or single-squeegee system. "Fully enclosed" in the true sense, especially suitable for volatile solvent units, saving solvents and improving the working environment.

|

|

Slotting Unit

The standard thickness of the slotting knife is 7mm, and the tooth-shaped slotting knife is made of alloy steel after heat treatment and has good hardness and toughness. Two-piece trimming knife with sharp edge and high precision. The shaft is made of high-quality 45# seamless steel pipe, the surface is ground and electroplated, and the movement is stable. Large displacement mechanism of the middle knife, trimming and cutting device, strong production adaptability. Snap-fit double-blade trimming knife, trimming smooth and clean, saving cost.

|

Packaging&shipping

FAQ

1.Q:What is the machine warranty?

A:one year.

2.Q:What is the production time while placing order?

A:About 20 days

3.Q:What is the delivery time?

A:40-60 days after get the payment.

4.Q:Can your company handle shipping for customers?

A:Yes, just give us destination sea port or container yard

5.Q:Does the packing strong?

A:Yes, all packages are double-checking before delivery

6.Q:Do you have machines in stock?

A: for standard model, we have a large quantity in stock. For

special model, we need 20-30 days to produce it for you.