Skywell Composite Technology Co.,Ltd |

|

| Resin No. | Resin Type | Curing Temperature ℃ | Features & applications | |||||

| #450 | Epoxy | 130 | High flex ,impact resistant,Fishing rob,Golf,rolling tube | |||||

| #469 | Epoxy | 130 | General industry,sporting equipment, bicycle frame,bicycle rims,Racket,hockey stick | |||||

| #477 | Epoxy | 130 | The better improved type than #469,Used in low RC ,high carbon modulus ,And for products with higher quality.Superior impact resistant ,better transparency,self-adhesive, sporting products like bike,racket,hockey,golf etc | |||||

| #4177 | Epoxy | 135 | Used in low RC ,high carbon modulus ,And for products with higher quality.Superior impact resistant ,half of transparency, higher self-adhesive | |||||

| #4619 | Epoxy | 135 | Not suitable for products asked by nice transparency apperance,And lower resin loss rate, general sporting products | |||||

| #502AB | Epoxy | 130 | Specially Designed for impact resistant, the #502A Most used in non-transparency products , And #502B used in transparency products ,like safe helmet | |||||

| #3016TG | Epoxy | 160 | impact resistant,most suitable for products that needs high temperature resistant,like road bicycle rims ,braking system | |||||

| #3017TG | Epoxy | 180 | Be suitable for products that needs high temperature resistant,flame retardant, TG point for 180℃ to 190℃ | |||||

| #8005 | Epoxy | 180 | Aircraft,PC products,Flame retardant, high standard under Germany DIN5510-2 ,And United State UL94V0. |

U Directional Carbon Fiber Prepreg 24 Ton Faw 100g 240 GPA Impact Resistant

1. What is the feature of carbon fiber ?

Carbon Fiber's Specisal Features and Characterizing Performances

1>. Light in Weight and Strong (Mechanical Performances)

2>. Excellent Dimensional Stability and Heat Resistance (Thermal Characteristics)

3>. Highly Electric Conductive and Excellent EMI Shielding Propaerty

4>. Magnificant X-ray Permeability

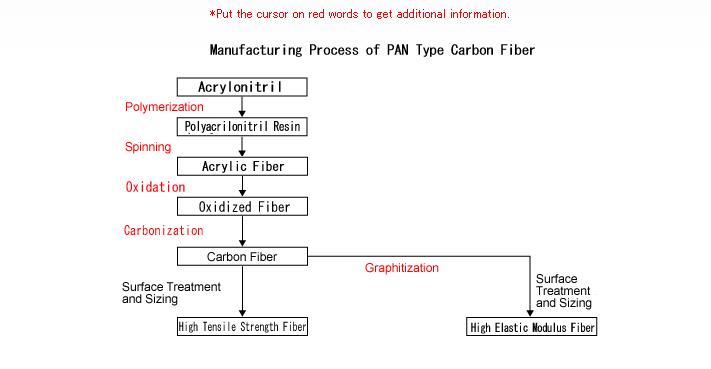

2. How to get Pan type carbon fiber ?

Carbon Fibers are manufactured by production processes as illustrated below. Manufacturers produce the fibers under different processing conditions to get assortments of products qualities.

3. To be suit for different manufacturer progress.

4. Application:

5. Resin system :

There are 8 different resin systems , Here you can find one that suits you . Please go to download our spreadsheet of products.

| Resin No. | Resin Type | Curing Temperature ℃ | Features & applications |

| #450 | Epoxy | 130 | High flex ,impact resistant,Fishing rob,Golf,rolling tube |

| #469 | Epoxy | 130 | General industry,sporting equipment, bicycle frame,bicycle rims,Racket,hockey stick |

| #477 | Epoxy | 130 | The better improved type than #469,Used in low RC ,high carbon modulus ,And for products with higher quality.Superior impact resistant ,better transparency,self-adhesive, sporting products like bike,racket,hockey,golf etc |

| #4177 | Epoxy | 135 | Used in low RC ,high carbon modulus ,And for products with higher quality.Superior impact resistant ,half of transparency, higher self-adhesive |

| #4619 | Epoxy | 135 | Not suitable for products asked by nice transparency apperance,And lower resin loss rate, general sporting products |

| #502AB | Epoxy | 130 | Specially Designed for impact resistant, the #502A Most used in non-transparency products , And #502B used in transparency products ,like safe helmet |

| #3016TG | Epoxy | 160 | impact resistant,most suitable for products that needs high temperature resistant,like road bicycle rims ,braking system |

| #3017TG | Epoxy | 180 | Be suitable for products that needs high temperature resistant,flame retardant, TG point for 180℃ to 190℃ |

| #8005 | Epoxy | 180 | Aircraft,PC products,Flame retardant, high standard under Germany DIN5510-2 ,And United State UL94V0. |

6. Carbon Fiber Specification :

| Type | Tickness | FAW (g/㎡) | RC (%) | Total weight (g/㎡) | Tensile strength (MPA) | Tensile Modulus (GPA) |

| U24T10000-34 | 0.105 | 100 | 34 | 151 | 4900 | 240 |