Dongguan Drow Precision Alloy Co., Ltd. |

|

Verified Suppliers

|

|

Application Field:

The tungsten carbide heading die are used for cold punching and heading of screw and nuts, it is

wear resistance and high toughness.Also, it is the ideal in making

non-ferrous metal, ferrous metal and other alloy.

Product Details--- Blanks For Cold heading Die Nibs

Properties of material general use as Cold heading Die Nibs as below shows:

| Grade | WC+Other | Co | Grain Size | Density | Hardness | Hardness | TRS |

| (±0.5%) | (±0.5%) | (g/cm²)±0.1 | HRA±0.5 | (HV30) | (kgf/mm²) | ||

| PK5 | 88 | 12 | Medium | 14.31 | 88.3 | 1200 | 340 |

| PK6 | 86 | 14 | Medium | 14.12 | 87.3 | 1100 | 320 |

| DE65 | 82 | 18 | Coarse | 13.75 | 85.0 | 910 | 300 |

| DE90 | 76 | 24 | Coarse | 13.22 | 82.8 | 760 | 270 |

| PS6 | 85 | 15 | Coarse | 13.8 | 86.0 | 990 | 270 |

| PS7 | 80 | 20 | Coarse | 13.4 | 85.3 | 940 | 270 |

| DV80 | 80 | 20 | Coarse | 13.58 | 84.0 | 830 | 280 |

| DV90 | 78 | 22 | Coarse | 13.39 | 82.5 | - | 240 |

| DV95 | 75 | 25 | Coarse | 13.12 | 81.5 | - | 220 |

Features of Different Grades Material :

PK5:High toughness cold heading die

PK6:High toughness cold heading die

DE65:Φ20 and below bolt die

DE90:Φ20~Φ50 bolt die

PS6:Inner diameterΦ2.1 and below nut and bolt die for stainless steel

PS7:Inner diameter Φ2.1 and above nut and bolt die for stainless steel

DV80:High impact die and fastener

DV90:High impact fastener

DV95:High impact fastener

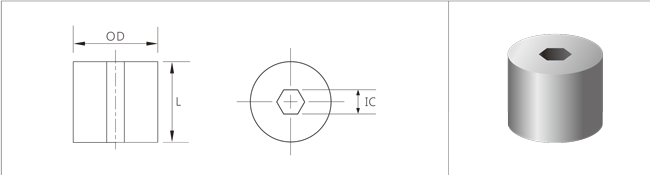

Product Specification

| Standard Dimension | ||

| OD (mm) | L (mm) | w (mm) |

| 15 | <40 | 5.4~8.4 |

| 18 | <45 | 5.4~11.7 |

| 20 | <45 | 5.4~11.7 |

| 25 | <45 | 5.4~21.9 |

| 30 | <45 | 5.4~21.9 |

| 35 | <45 | 5.4~21.9 |

| 40 | <50 | 5.4~21.9 |

| 45 | <50 | 5.4~24.2 |

| 50 | <50 | 5.4~29.4 |

| 55 | <50 | 5.4~31.8 |

| 60 | <50 | 5.4~35.4 |

| 70 | <50 | 5.4~42.0 |

| OD (mm) | L (mm) | ID (mm) |

| 8 | <20 | 1.2~5.0 |

| 10 | <20 | 1.2~6.0 |

| 12 | <30 | 1.2~8.0 |

| 15 | <40 | 1.2~10.0 |

| 18 | <45 | 1.2~10.0 |

| 20 | <45 | 1.2~10.0 |

| 22 | <45 | 1.2~10.0 |

| 25 | <45 | 1.2~17.7 |

| 30 | <45 | 1.2~24.0 |

| 35 | <45 | 1.2~25.0 |

| 40 | <50 | 1.2~25.0 |

| 45 | <50 | 1.2-25.0 |

| 50 | <50 | 1.2~25.0 |

| 55 | <50 | 1.2~25.0 |

| 60 | <50 | 1.2~25.0 |

| 70 | <50 | 1.2~25.0 |

| Standard Dimension | ||

| OD (mm) | L (mm) | IC (mm) |

| 15 | <40 | 4.0~6.9 |

| 18 | <45 | 4.0~9.3 |

| 20 | <45 | 4.0~9.3 |

| 25 | <45 | 4.0~13.0 |

| 30 | <45 | 4.0~18.0 |

| 35 | <45 | 4.0~21.0 |

| 40 | <50 | 4.0~24.3 |

| 45 | <50 | 4.0-27.8 |

| 50 | <50 | 4.0-31.5 |

| 55 | <50 | 4.0~31.5 |

| 60 | <50 | 4.0~37.8 |

| 70 | <50 | 4.0-37.8 |

| Other dimension available upon request | ||

Why choose us:

1.Advanced Technology: Dedicated in tungsten relevant material

research and development for tens of years. Constantly introducing

new technology and increase investing on high-end production

equipment.

2.Comprehensive Service: Fast response to customer demands,short

production cycle, rapid delivery to ensure delivery on time, and

thorough sales-after service. Always lead you to well position in

first round of market competition.

3.Rigorous QC: Rigorous inspection leads to well consistent

quality.

4.Fully equipped: Outstanding processing capacity, multiple

production lines, advanced metallurgy and machining equipment,

professional supporting facilities.

5.Cost-effective: Reasonable design and material selection lead us

to a competitive price, so that could help offer you more favorable

price of the same level products .

Quality Criteria

1.Hardness

2.Corrosion Resistance

3.Impact Strength

4.Toughness

5.Modulus of elasticity,Rigidity

6.Transverse Rupture Strength. Etc.

FAQ

Q1. Could you offer OEM and ODM service?

A:It’s okay , we have more than 10 years experience in OEM

service.Our professional R&D team is dedicated to design

products to fit various demands of customers. They can always offer

the professional advice and solutions for you!

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% balance before delivery. We'll show

you the photos of the products and packages before you pay the

balance.

Q3. What is your sample policy?

A: As for cemented carbide materials, we can supply the sample if

we have ready parts in stock, but the customers have to kindly pay

the sample cost and the courier cost

Q4. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery. Our production is based

on ISO9001,rigorous inspection and strictly quality control system

in our production process.

Q5: How do you keep long-term and good relationship with our

business?

A:1. Consistent quality and competitive price to ensure our

customers benefit ;

2. We respect every customer as our friend. We sincerely do

business and make friends with them, no matter where they come

from.

Q6: What else product can you buy from us?

A: Carbide insert,carbide end mill,carbide drill,carbide

boring,cutting tools&customized carbide precision molds.