Zhuzhou XinHua Cemented Carbide Co., Ltd. |

|

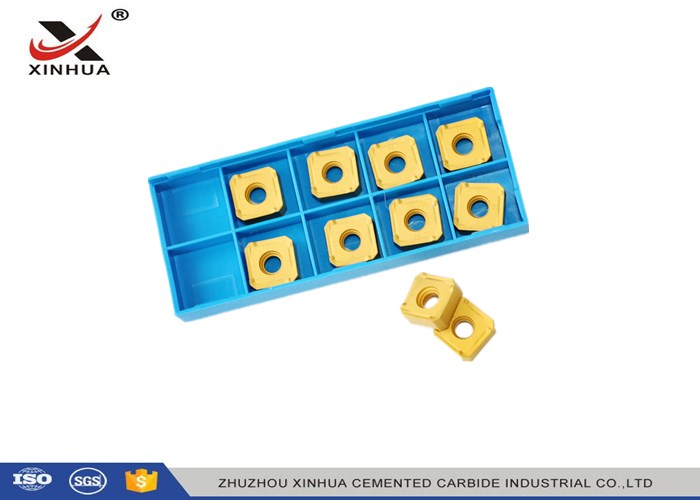

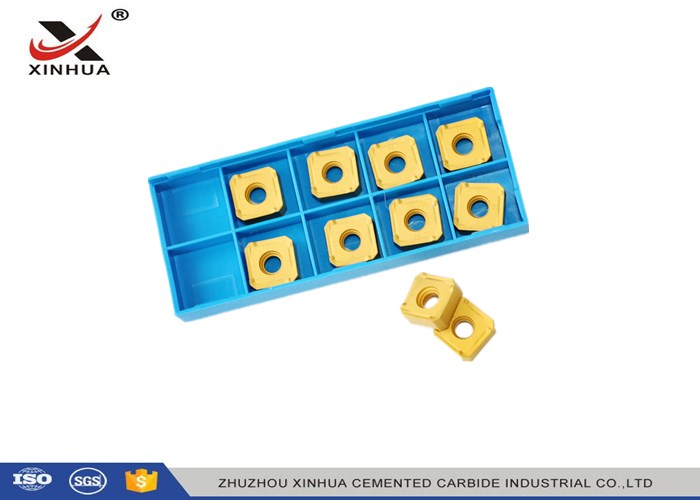

Coated SNMT1305AFN Carbide Milling Inserts Square Cutting tools for Cast Iron

Description:

Solid carbide provides better rigidity than high speed steel. It is extremely heat resistant and used for high speed applications on 45steel, cast iron, nonferrous materials, plastics and other tough-to-machine materials.

Product features

|

Specification:

| item name | SNMT1305AFN |

| Place of Origin | Zhuzhou |

| Model Number | various |

| Workpiece | Cast iron |

| Application | Turning,milling, |

| Color | Gold/Black/Gray |

| Hardness | various |

| Coating | PVD/CVD |

| Material | Tungsten Carbide |

Application:

CVD coated grade, which is the conbination of hard substrate and coating (mediu thick AL2O3+thick TiCN), has good flaking resistance. ITis suitable for turning and milling of cast iron at high speed, and light intermittent cutting can be supported evern at moderate speed. It is also suitable for millign of cast iron.

The combination fo thick coating and substate with good hardness and impact resistance gives the inserts excellent impact resistance and stablity under high remperature, and improves wear resistance of inserts. Inserts also satisfied the requirements of high speed and high feed rate when machining cast iron.

The shape of an insert has a major influence on the impact resistance of the carbide. The weakest section of a milling insert is the corner, which is exposed to constant interrupted cuts and extreme heat changes. Since a round insert has no corners, it is more secure than any other shape.

Consider the tremendous forces that are placed on a milling insert in a typical cut. As the insert enters the cut, it is subjected to a large compressive load. The initial contact between the cutting edge and the workpiece may be very unfavorable depending on the position of the cutter in relation to the workpiece.

As the insert moves through the cut, the chip thickness is constantly changing, varying the radial and axial cutting forces. Finally, as the insert leaves the workpiece, it is subjected to tensile stresses that break down the carbide. The chip bending away from the insert places large tensile or "ripping" stress on the face of the carbide.