Factop Pharmacy Machinery Company |

|

Verified Suppliers

|

|

FP DPP115 tablet alu pvc packing with blister packaging machine pharmaceutical industry

Introduction:

The blister packaging machine pharmaceutical industry has the advantages of extending the retention period, beautifying the product, and reducing packaging costs. Because this alu pvc packing machine occupies a small area, low investment, multi-functional use, high efficiency, no pollution, and low noise, it is an ideal packaging equipment for purifying workshops and hospital reagent rooms.

Features of FP DPP115 tablet alu pvc packing with blister packaging machine pharmaceutical industry:

1. Use domestic high-power transmission mechanism is adopted, and the main rotating shaft is driven by the chain, eliminating the errors and noise of other gear transmissions;

| Punching frequency: 10-40 times/min, 2400plate/hour | |

| Normal section: 57*80mm | Specification: 27*80mm one plate per time |

| Max forming area: 80*110*26mm | 60*100mm one plate per time |

| The feed stroke range: 20-70mm | |

| Yield rate: more than 99% | Motor power: 0.75kw |

| Forming heating power: 0.9kw | Low heating power: 0.9kw |

| Heat sealing power: 0.8kw | Gas mercury passenger volume: more than 0.3m3 |

| Cooling: circulating water or tap water | Weight: 450kg |

| Dimension: 1740*590*1190mm | |

| Packing material: Medicinal PVC 0.3*80MM Aluminum foil 0.023*80mm | |

Installation and precautions of FP DPP115 tablet alu pvc packing with blister packaging machine pharmaceutical industry:

1. Check whether the ground level is balanced before installation.

2. The ground wire should be connected at the location specified on the grounding label.

3. Full-time personnel training operation and maintenance.

4. The machine should be kept clean and tidy.

5. All parts of the machine must be refueled before production (refer to the operating provisions)

6. When the machine leaves the factory, the gearbox strap lubricating oil must be refueled before production.

7. It is recommended to use oil-free air compressor for this machine.

8. The pressure of forming, heat sealing, indentation and other parts should not be too high, otherwise it will affect the service life. There should be a floating margin of about one millimeter for the forming and indentation of the pad.

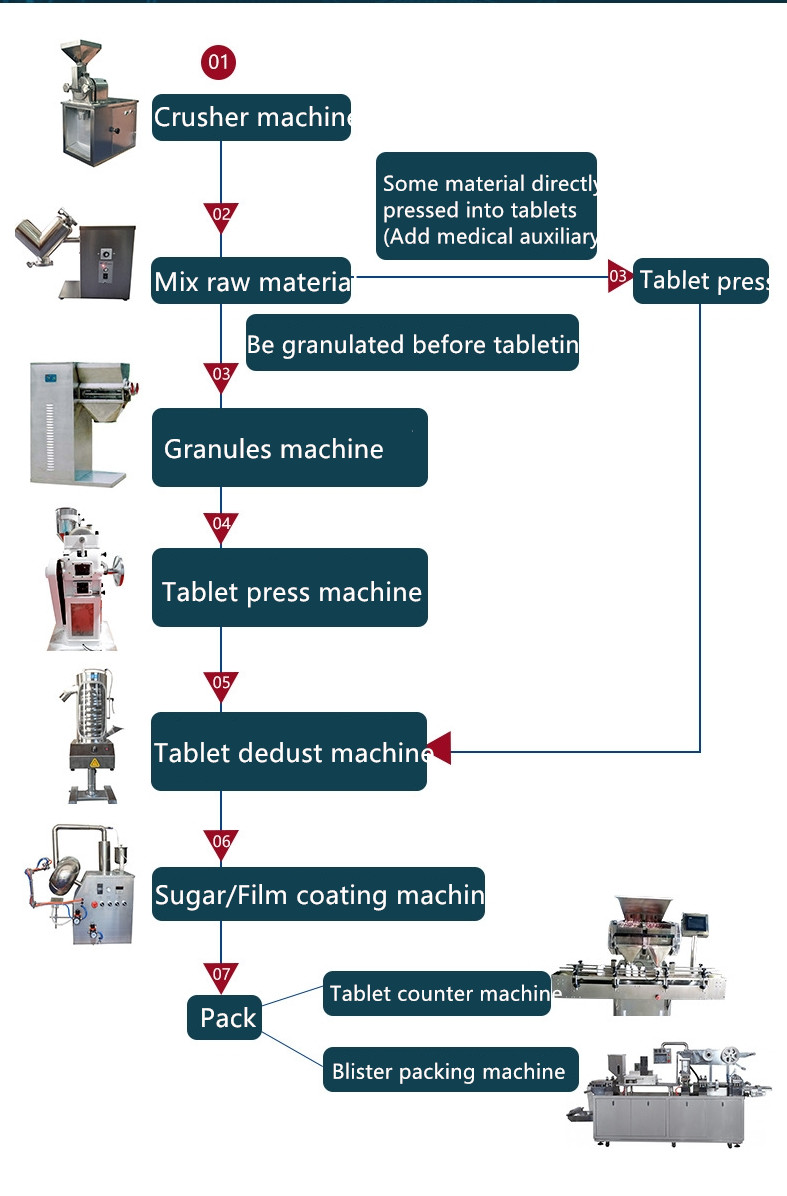

Pharmacy Process of Manufacturer price blister machine packing tablets pills pharmacy blister packaging machine: