Langfang Weber Cable Tray Co.,Ltd |

|

Verified Suppliers

|

|

11. Bolted Installation Method And Non-Flammable Fire Resistance 2" "3" "4" Products

Our comprehensive range of cable tray fittings is designed to support, protect, and manage cables in a variety of installations. These fittings are made from non-flammable materials, ensuring maximum safety and fire resistance in any environment. The product line includes a variety of sizes to accommodate different scales and complexities of cabling systems, making them suitable for a wide range of applications. The load capacity of our cable tray fittings is dependent on the size and material selected, ensuring that you can choose the most appropriate option for your specific needs.

Each fitting in our range is UL Listed and NEMA Rated, highlighting our commitment to quality and adherence to stringent industry standards. These certifications assure customers that our cable tray fittings have been rigorously tested for safety and durability. Our fittings are designed to work seamlessly with existing cable management systems, providing a reliable and robust solution for organizing and protecting your cables.

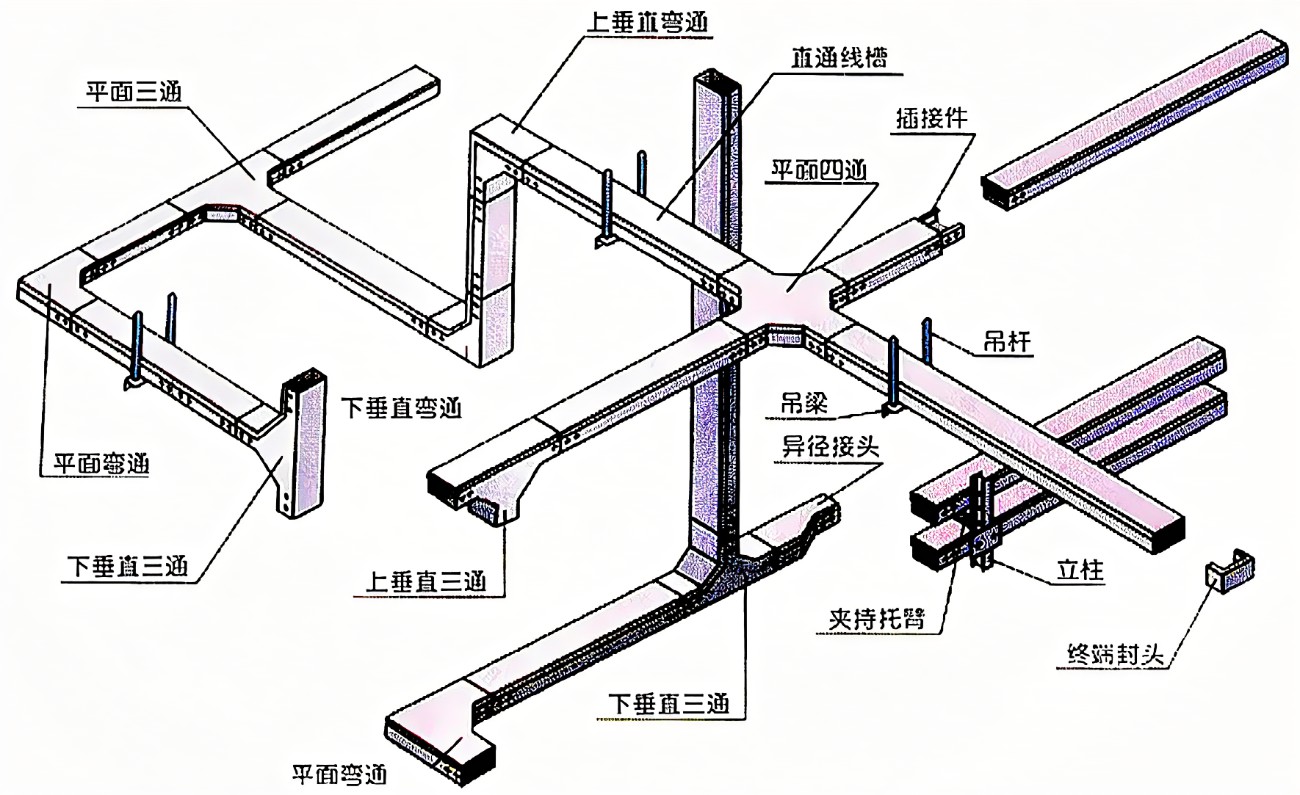

The various fitting options available within our product line include a collection of bends, reducers, tees, crosses, and risers, each designed to create a seamless and secure cable pathway. The rectangular shape of our fittings ensures efficient use of space and a clean aesthetic, which is particularly important in exposed installations. These versatile fittings can be easily integrated with straight sections of cable tray to navigate around obstacles, change elevations, and branch off in multiple directions, offering the flexibility needed in complex cabling layouts.

Our fittings' load capacities are meticulously classified to match different types and weights of cables. Whether you're working with lightweight data cables or heavy-duty power cables, there is a cable tray fitting within our range to support your installation. This versatility is a testament to the engineering and design quality of our products, as we strive to provide solutions that are both practical and reliable for any scenario.

Installation of our cable tray fittings is designed to be straightforward and efficient. The modular design allows for quick assembly, which can significantly reduce installation time and labor costs. This ease of installation does not compromise on strength or reliability; once in place, our fittings provide a durable, long-lasting cable management solution. Regular inspections and maintenance can be performed effortlessly due to the accessible design, ensuring that your cable management system remains in optimal condition throughout its service life.

In summary, our cable tray fittings embody a perfect blend of safety, versatility, and durability. With their non-flammable nature, various sizes, load-dependent capacities, UL Listing, NEMA ratings, and rectangular shape, these fittings are engineered to meet the highest standards of safety and functionality. The various fitting options available cater to the diverse needs of cable management systems, providing a comprehensive solution for organizing and protecting your cables. Whether you are planning a new installation or upgrading an existing one, our cable tray fittings offer the reliability and quality you need to ensure a safe and efficient cable management system.

| Attribute | Detail |

|---|---|

| Fire Resistance | Non-flammable |

| Finish | Galvanized |

| Durability | Long-lasting |

| Material | Steel |

| Installation Method | Bolted |

| Size | Various sizes available |

| Application | Indoor and outdoor use |

| Flexibility | Can be easily modified and adapted |

| Shape | Rectangular |

| Corrosion Resistance | High |

Cable tray fittings, an essential component of the modern electrical infrastructure, are designed to provide a robust and reliable solution for organizing and protecting electrical wires and cables. These fittings come with a high corrosion resistance, ensuring long-term durability and performance in various environments, from industrial settings to commercial buildings. The rectangular shape of these fittings is conducive to a neat and orderly cable management system, allowing for easy cable routing and distribution.

The installation method for these cable management fittings is bolted, ensuring a secure and stable setup. This bolting mechanism is straightforward, allowing for quick assembly and disassembly when necessary for system updates or maintenance. The load capacity of cable tray fittings is contingent upon the size and material used; however, manufacturers provide a range of options to accommodate different weights and sizes of cables, ensuring that the system is tailored to meet specific requirements.

One of the key application occasions for these fittings is within industries where safety and reliability are paramount. The high corrosion resistance means that they are particularly suited for use in harsh environments where exposure to chemicals or moisture is a concern. This could include chemical plants, wastewater treatment facilities, and marine applications where traditional materials might fail.

Furthermore, the certifications that these products boast, such as UL Listed and NEMA Rated, attest to their quality and compliance with stringent industry standards. These certifications provide assurance that the products are safe for use and have met the necessary requirements for performance and reliability. Consequently, contractors and engineers can select these fittings with confidence for projects that require certified solutions.

In addition to industrial use, cable tray fittings are also widely used in commercial construction, such as office buildings, data centers, and retail spaces. The ease of installation and the ability to handle various load capacities make these fittings adaptable to the cable management needs of these environments, ensuring that electrical systems are organized, accessible, and up to code.

Overall, cable tray fittings play a critical role in cable management systems. Their corrosion resistance, ease of installation, versatility in load capacity, and adherence to certifications make them an ideal choice for a wide range of applications. Whether in demanding industrial settings or sleek commercial spaces, these fittings provide the necessary support and protection to maintain system integrity and ensure the safe and efficient operation of electrical infrastructures.

Our Cable Tray Fittings come with comprehensive technical support and services designed to ensure you can make the most of our products. Our team of experts is committed to providing you with the guidance and assistance you need for the selection, installation, and maintenance of our fittings. We offer a range of support options to cater to your specific requirements, including product documentation, installation guides, and technical specifications. Our dedicated support services aim to provide you with the confidence that our cable tray fittings will meet your project's needs with reliability and efficiency. Whether you are at the planning stage or in the midst of installation, our technical support team is here to help you achieve the best possible outcome with our products.

Our cable tray fittings are meticulously packaged to ensure they arrive at your destination in perfect condition. Each fitting is first individually wrapped to prevent surface damage and scratches during transit. The wrapped fittings are then carefully arranged within sturdy cardboard boxes, which are clearly labeled with the product information and handling instructions. The boxes are sealed with heavy-duty packing tape to secure the contents.

For shipping, the sealed boxes are placed onto pallets, which are then shrink-wrapped to further protect the products from any external environmental factors such as moisture or dirt. The pallets are also strapped to provide additional stability during handling and transportation. We utilize trusted courier services to ensure your order is delivered promptly and safely, with tracking information provided so you can monitor your shipment's progress until it reaches you.

Q1: What materials are used to make cable tray fittings?

A1: Cable tray fittings are typically made from materials such as galvanized steel, stainless steel, aluminum, or fiberglass. The choice of material depends on the environment where the cable tray will be installed and the level of corrosion resistance required.

Q2: Can cable tray fittings be used outdoors?

A2: Yes, cable tray fittings can be used outdoors. However, it is important to select the right material and finish, such as hot-dip galvanized or stainless steel, to withstand varying weather conditions and prevent corrosion.

Q3: How do I choose the right size cable tray fitting for my application?

A3: The size of the cable tray fitting should be based on the width and depth of the cable tray you are using as well as the number and type of cables that need to be supported. It's important to ensure that the fitting is compatible with the cable tray system and provides enough space for easy installation and cable management.

Q4: Are there different types of cable tray fittings for various applications?

A4: Yes, there are various types of cable tray fittings designed for different applications, including horizontal elbows, tees, crosspieces, reducers, and risers. Each type of fitting is used to create different configurations in the cable tray system, such as turns, junctions, transitions, and elevation changes.

Q5: How are cable tray fittings installed?

A5: Cable tray fittings are typically bolted or clamped onto the ends of the cable trays to form the desired layout. The installation process may vary depending on the specific type of fitting and the cable tray system used. It's important to follow the manufacturer's installation instructions and adhere to local codes and standards for a safe and secure installation.