Shenzhen Bwin Precision Tools Co., Ltd. |

|

Characteristic:

Carbide material introdution

| Item Grade | HRC45 (YG10X ) | HRC55 (YL10.2 & WF25) | HRC60 (Germany K44 &K40) | HRC65 (Sandvik H10F) |

Details | Grain size 0.7um Co10% Flexural strength 3320N/mm2 | Grain size 0.6um Co10% Flexural strength 4000N/mm2 | Grain size 0.5um Co12% Flexural strength 4300N/mm2 | Grain size 0.5um Co10% Flexural strength 4300N/mm2 |

| Application | Suitable for general steel | General steel, stainless steel, cast iron | High hard material, steel, cast iron, etc | Titanium alloy, high-temperature alloy, harden material, etc |

| Coating Classifying and Advantage | |||||

| Item | Coating Type | AlTiN | TiAlN | TiSiN | NaCo |

Characteristic | Hardness(HV) | 3300 | 2800 | 4300 | 42(GPA) |

| Thickness(UM) | 2.5-3 | 2.5-3 | 3 | 3 | |

| Oxidation Temp.(°C) | 900 | 800 | 1000 | 1200 | |

| Friction Coefficient | 0.35 | 0.3 | 0.25 | 0.4 | |

| Color | Black | Bronze | Bronze and gold | Blue | |

Advantages | High heat stability | Normally cutting | Suitable for heavy cutting, and high hardness cutting | For high precision cutting | |

| Suitable for high speed, dry cutting | Suitable for cutting mould steel, stainless steel | Suitable for high hardness cutting, mould steel processing | |||

| Most suitable for carbide cutting tools, turning insert | |||||

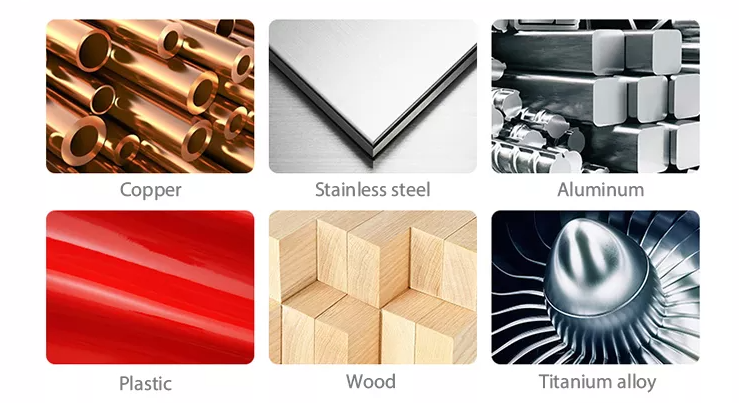

Applications of carbide end mill

Machinable workpieces include cast iron, alloy steel, carbon steel, tool steel, quenched and tempered steel, stainless steel, copper, aluminum alloy, copper alloy, plastic, wood, magnesium alloy, zinc alloy, aluminum parts, etc

Product specifications of carbide end mill

| Specification | Flute Dia(φ) | Flute Length (C) | Shank Dia(D) | Overall Length(L) |

| R0.5*2*d4*50L | 0.5 | 2 | 4 | 50 |

| R0.75*3*d4*50L | 0.75 | 3 | 4 | 50 |

| R1*4*d4*50L | 1 | 4 | 4 | 50 |

| R1.25*5*d4*50L | 1.25 | 5 | 4 | 50 |

| R1.5*6*d4*50L | 1.5 | 6 | 4 | 50 |

| R1.75*7*d4*50L | 1.75 | 7 | 4 | 50 |

| R2*8*d4*50L | 2 | 8 | 4 | 50 |

| R2.5*10*d5*50L | 2.5 | 10 | 5 | 50 |

| R3*12*d6*50L | 3 | 12 | 6 | 50 |

| R4*16*d8*60L | 4 | 16 | 8 | 60 |

| R5*20*d10*75L | 5 | 20 | 10 | 75 |

| R6*24*d12*100L | 6 | 24 | 12 | 100 |

| R7*28*d14*150L | 7 | 28 | 14 | 150 |

| R8*32*d16*100L | 8 | 32 | 16 | 100 |

| R9*36*d18*100L | 9 | 36 | 18 | 100 |

| R10*40*d20*100L | 10 | 40 | 20 | 100 |

Tips: The above specifications are standard Size, with a large amount of stock. At the same time, we support OEM customized production, the diameter is 0.2mm to 25mm, the Total length is 50mm to 200mm, include inch size end mill , the number of Flute is 4F, 5F, 6F, 8F and the logo could becustomized.

Instructions of carbide end mill

1. Handle with care to avoid impact damage.

2. When loading and unloading milling cutters, it is advisable to use a cloth to protect them from injury to hands or damage to the cutting edge due to falling

3. During milling, the milling cutter should be fully separated from the working object before starting the machine to avoid damaging the cutter due to impact on the working object

4. The distance between the cutting edge of the milling cutter and the collet should be as short as possible to reduce the vibration of the milling cutter. When selecting the length of the cutting tool, it should be avoided to be too long

Advantage

1. Source manufacturer

2. Imported grinding machines and testing equipment

3. Professional technical team

4. Intelligent CNC workshop

5. Complete specifications and sufficient supply of goods

FAQ