Shenzhen Bwin Precision Tools Co., Ltd. |

|

Description:

Carbide material introdution

| Item Grade | HRC45 (YG10X ) | HRC55 (YL10.2 & WF25) | HRC60 (Germany K44 &K40) | HRC65 (Sandvik H10F) |

Details | Grain size 0.7um Co10% Flexural strength 3320N/mm2 | Grain size 0.6um Co10% Flexural strength 4000N/mm2 | Grain size 0.5um Co12% Flexural strength 4300N/mm2 | Grain size 0.5um Co10% Flexural strength 4300N/mm2 |

| Application | Suitable for general steel | General steel, stainless steel, cast iron | High hard material, steel, cast iron, etc | Titanium alloy, high-temperature alloy, harden material, etc |

| Coating Classifying and Advantage | |||||

| Item | Coating Type | AlTiN | TiAlN | TiSiN | NaCo |

Characteristic | Hardness(HV) | 3300 | 2800 | 4300 | 42(GPA) |

| Thickness(UM) | 2.5-3 | 2.5-3 | 3 | 3 | |

| Oxidation Temp.(°C) | 900 | 800 | 1000 | 1200 | |

| Friction Coefficient | 0.35 | 0.3 | 0.25 | 0.4 | |

| Color | Black | Bronze | Bronze and gold | Blue | |

Advantages | High heat stability | Normally cutting | Suitable for heavy cutting, and high hardness cutting | For high precision cutting | |

| Suitable for high speed, dry cutting | Suitable for cutting mould steel, stainless steel | Suitable for high hardness cutting, mould steel processing | |||

| Most suitable for carbide cutting tools, turning insert | |||||

Feature:

| Specification | Flute Dia(D) | Flute Length (C) | Shank Dia(D) | Overall Length(L) |

| Φ4*10*d4*50L | 4 | 10 | 4 | 50 |

| Φ5*13*d5*50L | 5 | 13 | 5 | 50 |

| Φ6*15*d6*50L | 6 | 15 | 6 | 50 |

| Φ8*20*d8*60L | 8 | 20 | 8 | 60 |

| Φ10*25*d10*75L | 10 | 25 | 10 | 75 |

| Φ12*30*d12*75L | 12 | 30 | 12 | 75 |

| Φ8*35*d8*100L | 8 | 35 | 8 | 100 |

| Φ10*40*d10*100L | 10 | 40 | 10 | 100 |

| Φ12*45*d12*100L | 12 | 45 | 12 | 100 |

| Φ14*45*d14*100L | 14 | 45 | 14 | 100 |

| Φ16*45*d16*100L | 16 | 45 | 16 | 100 |

| Φ18*45*d18*100L | 18 | 45 | 18 | 100 |

| Φ20*45*d20*100L | 20 | 45 | 20 | 100 |

Instructions:

1. Before using the carbide end mill, please measure the tool deflection. If the tool deflection accuracy exceeds 0.01mm, please correct it before cutting.

2. The shorter the carbide e extends out of the collet, the better. If the tool extends out longer, reduce the speed, feed speed or cutting amount.

3. In case of abnormal vibration or sound during cutting, please reduce the speed and cutting amount until the situation is improved.

4. Spray type and air jet type are preferred for steel cooling, which can improve the use effect of carbide end mill.

5. Note: Not suitable for low speed machines such as rotary table and electric hand drill.

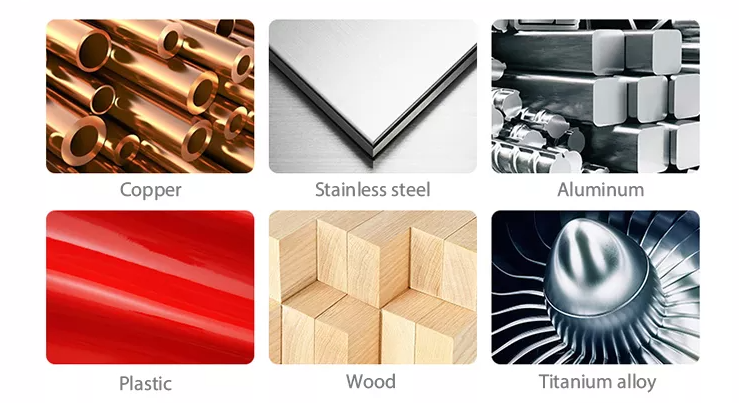

Applications:

Pre-hardened Steel, stainless steel, Die steel, steel plate, Heat-resistant steel,pipe, copper and aluminum, cast iron, Nonferrous Metal, Wood, Plastic,FRP and sO on. General-purpose operation slotting, rilling, profiling.

Q1: The tool breaks when the feed direction changes

Solution:

(1) Use circular interpolation (NC machine tool) or temporarily stop (temporarily) feeding.

(2) Reduce (decrease) the feed rate before and after the direction change.

(3) Replace the fixture or spring collet.

Q2. Problem: The blade tip is partially chipped

(1) Use manual grinding to chamfer the corners.

(2) Change the forward milling to reverse milling.

Q3. Problem: Partial collapse of the cutting interface

Solution:

(1) Change the forward milling to reverse milling.

(2) Reduce cutting speed.