Bronze alloy Gleitlager bushings, commonly referred to as sliding

bearings or bushings, are precision-engineered components that

incorporate graphite inserts for enhanced performance. These

bushings are designed to provide smooth and reliable sliding motion

in various mechanical and industrial applications.

The bronze alloy base of these Gleitlager bushings offers excellent

strength, durability, and corrosion resistance. Bronze alloys are

widely used in sliding bearings due to their ability to withstand

high loads, pressures, and temperatures. The alloy's composition

typically includes copper, tin, and other elements that enhance its

mechanical properties.

The key feature of these Gleitlager bushings is the graphite

insert. Graphite is a natural lubricant that possesses low friction

coefficients and excellent wear resistance. By embedding graphite

particles into the bronze alloy base, the bushings achieve

self-lubricating properties. This eliminates the need for frequent

relubrication, reducing maintenance costs and downtime.

The graphite insert also improves the bushings' sliding

performance. As the bushings rotate or slide against other

surfaces, the graphite particles act as a lubricating layer,

reducing friction and wear. This ensures smooth and reliable

operation, even under high loads and speeds.

Bronze alloy Gleitlager bushings with graphite inserts are widely

used in various applications, including hydraulic systems, pumps,

compressors, and other industrial equipment. They are particularly

suited for applications where precise alignment and smooth

operation are critical.

In summary, bronze alloy Gleitlager bushings with graphite inserts

offer a reliable and cost-effective solution for ensuring smooth

and reliable sliding motion in mechanical and industrial

applications. The combination of bronze alloy's strength and

durability and graphite's self-lubricating properties makes these

bushings a preferred choice for a wide range of applications.

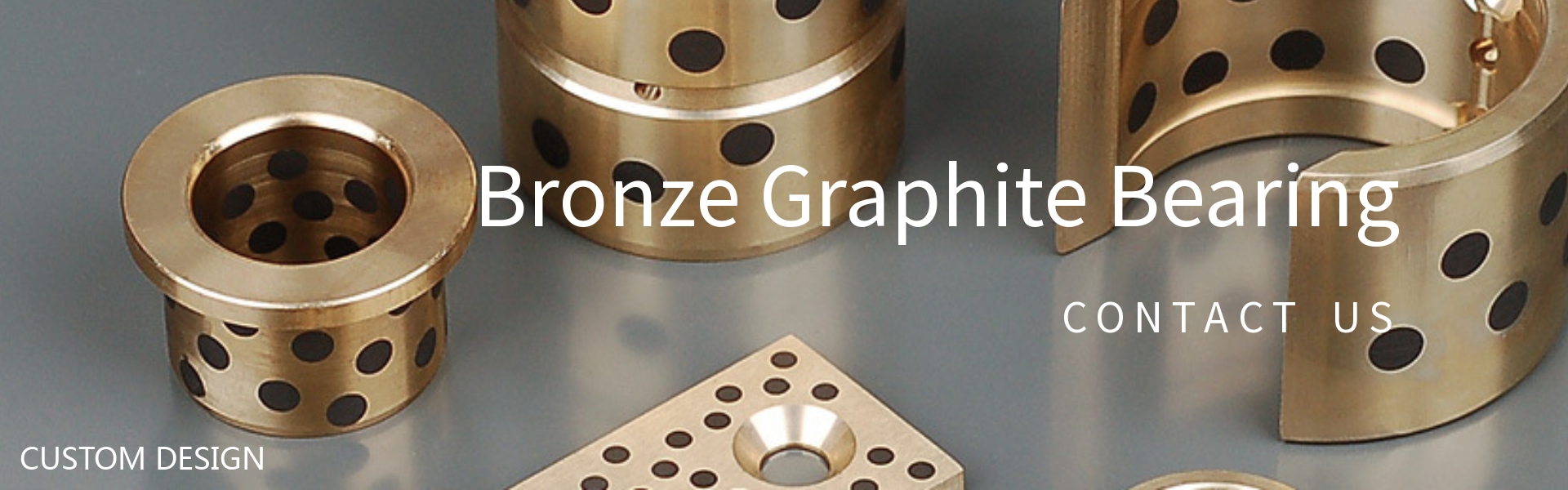

Oilless Bushings | Self-lubricating Bronze Bushing Graphite

Plugged

High quality at cost-effective prices

Maintenance free flanged bush, thin walled, bronze with solid

lubricant Highly wear- and dirt-resistent, insertable at high

temperature.

Gleitlagerbuchsen Bronze, Bearing Ring Bronze Alloy Bushing With

Graphite Inserted, Bronze Graphite Bearing

It is a high-performance solid lubrication product that is inserted Graphite or MoS2 solid lubricant on a matrix of colliers brass. It has broken through the limitation of general bearing lubrication

by oil film. In the use process, through the friction heat to make the solid

lubrication and the shaft friction, the formation of oil, powder

co-lubrication of excellent conditions, not only protect the shaft

from wear but also make the solid lubrication characteristics

eternal. Its hardness is higher than ordinary copper sleeve one

time, wear resistance is also one time.

If you want a customized product, please contact us, we also

provide the best service.

Guide bush with collar, Bronze with solid lubricant

| Material | CuZn25Al5Mn3Fe3 |

| Density (g/cm³) | 8.0 |

| Hardness (HB) | >210 |

| Tensile Strength (N/mm²) | >750 |

| Elongation (%) | >12 |

| Coefficient of linear expansion | 1.9 |

| Usage temperature(℃) | -40~+300 |

| Max. Dynamic Load(N/mm²) | 100 |

| Max. speed (m/min) | 15 |

| Max. PV (N/mm²*m/min) | 200 |

| Permanent compression deformation (300N/mm²) | <0.01 |

Feature

·The reduction in operating costs significantly reduces the use of

lubricants and equipment maintenance costs, and also eliminates the

risk caused by insufficient oil supply.

·There is no need to save the cost and time of oil supply device,

oil injection hole, oil tank processing and oil supply device,

processing fee, assembly fee, etc., which can greatly reduce the

manufacturing cost.

·The recovery and environmental protection of lubricating oil do not

require waste oil recovery and treatment, which is conducive to

environmental protection.

·Shortening the design time oil-free can greatly simplify the design

and structure, reduce the cost and save the design time. In

addition, the use of self-lubricating bearings can also improve the

mechanical properties, prolong the service life and improve the

reliability and other aspects to obtain significant results.

Use method and notes

·In the possible case, the design uses the standard specification

as far as possible.

·Please note that there is no foreign body in the assembly.

·After using the sliding surface, formed by solid lubricant oil

film in surface with black or gray-black phenomenon, please do not

scrub, as usual.

·Before the assembly, if the lubricating oil applied to the

grinding parts, can shorten the running-in period, conducive to the

operation of machinery, operation.

·When the assembly should be slowly pressed into, it is strictly

forbidden to beat, so as to avoid damage to the bearing and

deformation.

·Design, different parts should be selected with appropriate

material, in order to improve the mechanical performance, to extend

the service life of the bearing.

·In the high load, reciprocating motion, the proposed use of screw

fixation.

·In freshwater, seawater, and in the sea, on the use of stainless

steel or surface plating.

Advantages

·Flexible design, simple, convenient with wide applications

The designing of the oil-feeding system is both a labor-consuming

and time-consuming job. Therefore, the neglecting of the

oil-feeding apparatus in the designing of solid Lubricant bearings

saves the cost of the oil-feeding apparatus. Besides, for various

specific circumstances, the solid lubricant bearings can be

designed into various types to meet the requirements thereof. The

use of solid lubricant bearings can greatly reduce the cost of

mechanical maintenance and oil.

· FunctionaI in absence of oiI

Since the Iinear expansibility of solid Iubricant is greater than

metallic matrix's, when the movement of solid lubricant bearings

start, the Iubricant is transferred onto the parts in abrasion thus

realizing the self-lubrication. Therefore, the lubricant bearings

can be used in circumstances where oiling and greasing are

difficult or impossible and they perform excellent Lubrication even

under low-speed and high Road circumstances.

·Cost efficiency

The traditional mechanical designing requires frequent oiling

maintenance; oil gauge check shall be performed to ensure the

passage of the oil supplying apparatus is clear. Since the

periodical oiling can cause pollution to the machines themselves as

well as to the ambient surroundings, resulting in an increase of

the maintenance cost,the realization of self-lubrication can not

only make the environment clean but greatly reduce the Lubricating

costs as well.

· Excellent performance under high-load, Iow-speed circumstances

The solid lubricant bearings are made of rotational cast

high-strength copper as the matrix, which functions as Road

bearers. Besides, lubricant bearings use specially formulated

graphite as Lubricant, ensuing excellent self-lubrication.

Combining the advantages of both the matrix and Lubricant,

lubricant bearings are capable of exerting their wonderful

performance in circumstances with high load and low speed.

· In circumstances where it is difficult for the oiI films to

generate, such as the alternative movements, swinging movements and

frequent on-and-off, solid lubricant bearings highlights their

excellent resistance to abrasion. As the principle of the arrangement of lubricant bearings

Iubricant is to ensure that each part of the equipment is involved

in the Iubrication throughout the movement, the Iocation of the

Iubricant shalI be determined according to the movement direction

of the parts in abrasion.

· Excellent chemical resistance and corrosion resistance

The Lubricant for lubricant bearing is formulated out of the

abrasion-resistant materials such as graphite and PTEE and has

stabilized molecular structure. The metallic matrix can be selected

according to the various chemical resistance and corrosion

resistance accordingly. Therefore, the lubricant

bearing enjoys high chemical resistance and corrosion

resistance.

·The cost of the products is more competitive and compared with

other products of the same kind, the solid lubricant bearings

feature in longer service hours, less maintenance, longer

replacement period, and better performance.

Application

·Water engineering

·Automotive products line

·Rolling equipment

·Mining machinery

·Ships

·Other industrial area

Solid lubricant

| lubricant | character | Typical application |

| Graphite + additive | Good chemical tolerance, low friction factor, ultimate service

temperature +400℃. | Suitable for general industrial applications, long exposure to air. |

| PTFE+MoS2+additive | Low friction factor, good water lubrication performance, limit

service temperature +300℃. | Suitable for water lubrication conditions, such as underwater or

sea for ships, turbines or steam turbines, etc. |