JIAXING VIIPLUS INTERNATIONAL TRADING CO.,LTD |

|

Valve & Pump Bimetal Bearing Bushes Gear Transmission Parts are precision-engineered components that meet the highest quality standards, as evidenced by their ISO 9001 certification. These bushings are specifically designed for use in valves and pumps, as well as in gear transmission systems, where they play a crucial role in ensuring smooth and efficient operation.

The bimetallic construction of these bearing bushes combines the strength and durability of one metal with the lubricity and wear resistance of another. This unique combination of properties enables the bushings to withstand the high loads and stresses associated with valve and pump operation, as well as the rigorous demands of gear transmission systems.

The ISO 9001 certification guarantees that these bearing bushes are manufactured according to internationally recognized quality management systems. This ensures consistent product quality, reliability, and performance, giving customers the confidence that they are receiving the best possible products for their applications.

In addition to their superior performance, these Valve & Pump Bimetal Bearing Bushes Gear Transmission Parts are also designed for ease of installation and maintenance. Their precision-fit design ensures a secure and reliable connection, while their durable construction minimizes the need for frequent replacements or repairs.

Overall, Valve & Pump Bimetal Bearing Bushes Gear Transmission Parts ISO 9001 Passed are a high-quality solution for improving the performance and reliability of valve and pump systems, as well as gear transmission systems.

Manufacturer and stockist of gear transmission bushing & bearings.viiplus is a the profession design,made and sales self-lubricatingbearing company for pump &

fluid equipment.all kinds of hydraulic pump, hydraulic motor and

other related polymer automatic lubrication series liner, oil

distribution pan and other parts.

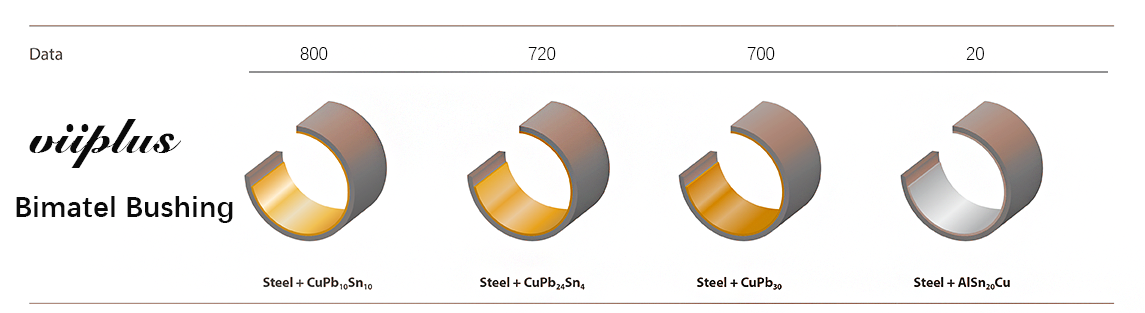

JF800 bimetallic bearing, is a low carbon steel plate as the matrix

material, surface sintering CuPb10Sn10 or CuSn6Zn6Pb3 steel copper alloy products.The product is one of the most powerful bearing capacity of double alloy bearing, the balance bridge bushing and

gasket of heavy duty vehicle;The driven wheel of a bulldozer;

Automobile steel plate bushing, all use this product.It is a kind

of high load and low speed sliding bearing which is widely

used.Alloy layer material:

CuPb10Sn10 or CuSn6Zn6Pb3

Maximum bearing pressure: 65N/mm2

Maximum service temperature: 260℃

Hardness of alloy layer: HB70~100

| BIMETAL BUSHINGS | BIMETAL BUSHINGS | BIMETAL BUSHINGS | BIMETAL BUSHINGS | BIMETAL BUSHINGS | BIMETAL BUSHINGS | |

| CuPb10Sn10 | CuPb24Sn4 | CuPb6Sn6Zn3 | CuSn10 | CuSn6.5P | AlSn20Cu | |

| Cu | allowance | allowance | allowance | allowance | allowance | 0.7~1.3 |

| Pb | 9.0~11.0 | 21.0~27.0 | 2.0~4.0 | 0.1 | 0.1 | - |

| Sn | 9.0~11.0 | 3.0~4.5 | 5.0~7.0 | 9.0~10.0 | 6.0~6.8 | 17.5~22.5 |

| Zn | 0.5 | 0.5 | 5.0~7.0 | 0.3 | 0.3 | - |

| P | 0.1 | 0.1 | 0.1 | 0.1 | 0.1~0.3 | - |

| Fe | 0.5 | 0.7 | 0.6 | 0.5 | 0.6 | 0.7 |

| Ni | 0.5 | 0.3 | 0.3 | 0.5 | 0.5 | 0.1 |

| Al | - | - | - | - | - | allowance |

| Other | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| alloy composition | alloy hardness | international standard |

| CuPb10Sn10 | 80~120HB | JIS-LBC3. JIS-LBC3. SAE-797. DIN CuPb10Sn. UNS C93700. CLEVITE F100. |

| CC495KDAIDO L10. D. A. B. D57. Federal Mogul HF2. Glacier SY. GLYCO66. ACL F100 | ||

| CuPb24Sn4 | 45~70HB | JIS-LBC6. JIS-LBC6. SAE-799. GLYCO 68. DAIDO L23. Clacie rsx. ACL F250 |

| CuPb6Sn6Zn3 | 70-100HB | DIN17670 |

| CuSn10 | 70-100HB | DIN G-CuSn10 ;BS PB1 |

| CuSn6.5P | 70-100HB | DIN CuSn6(2.1020); JIS H3110 |

| AlSn20Cu | 30~40HB | JIS-AJL. SAE-783. GLYCO74. Glacier AS15. ACL820 |

Bimetal Bushings Clinch Type

| Wrapped composite sliding bearing, Copper-plated or tin-plated steel/bronze, DIN 1494 / ISO 3547, Maintenance-free, With lubrication pockets | |||

| TECHNICAL DETAILS | |||

| Specific load capacity static | ≤ 250 [N/mm2] | Temperature strain | - 40 [°C] to + 250 [°C] |

| Specific load capacity dynamic | ≤ 140 [N/mm2] | ||

| Sliding speed | ≤ 2.5 [m/s] | Max. PV-value | 2.8 [N/mm² x m/s] |

| Friction value | 0.04 [µ] to 0.12 [µ] | Percentage contact area | > 75 [%] |

| MATERIALS | |||

| Support material | Steel copper-plated or tin-plated | Sliding layer | CuPb10Sn10 |

| TOLERANCE DETAILS | |||

| Housing Ø | H7 | Shaft tolerance | f7 to h8 |

| Bushing inner-Ø after mounting | H9 | ||

| SHAFT MATERIAL | |||

| Steel, hardened or untempered | |||

| Surface roughness ≤ Ra 0.8 | |||

| PROPERTIES | |||

| For high load capacity and oscillating movement, as well as for rough operation and temperature load. Long-run lubrication because of lubricant storage. | |||

| RANGE OF APPLICATION | |||

| Track rollers, construction machines, crane construction, agricultural machines (impact loading) | |||

| MAINTENANCE | |||

| It is a low-maintenance bushing material. An initial greasing during installation is necessary, after that periodic greasing with oil or grease is mandatory. | |||

| MOUNTING ADVISE | |||

| Housing | Mounting bevel min. 1.5 mm x 15-45° | ||

| Shaft | Mounting bevel 5 mm x 15°, edges rounded | ||

| The application of an adequate force fitting mandrel is advisable. Grease lubrication of the outer surface may be necessary when mounting. | |||

| Gluing | Adhesive should not contact the sliding surface! | ||

1. Low-friction surface film

2. Bearing layer (bronze)

3. Solid lubricant (graphite)

4. Steel backing

This is a bimetal bearing material in which bronze alloy comprise a two layer structure with a steel backing. This structure, whose mechanical strength is high, can be used under lubricated conditions and high-speed/high-load operation. It can be made from a variety of different materials, depending on the application, use conditions and lubrication.

Sintered SAE797 Layer + Steel Backed + Copper Plating /

Tin-Plating(CuPb10Sn10)

Sintered SAE799 Layer + Steel Backed + Copper Plating /

Tin-Plating(CuPb24Sn4)

Sintered SAE48 Layer + Steel Backed + Copper Plating / Tin-Plating

(CuPb30)

Sintered SAE783 Layer + Steel Backed+ Copper Plating / Tin-Plating

(AlSn20Cu)

http://www.bronzegleitlager.com

david@viiplus.com

| Wrapped composite sliding bearing, Copper-plated or tin-plated steel/bronze, DIN 1494 / ISO 3547, Maintenance-free, With lubrication pockets | |||

| TECHNICAL DETAILS | |||

| Specific load capacity static | ≤ 250 [N/mm2] | Temperature strain | - 40 [°C] to + 250 [°C] |

| Specific load capacity dynamic | ≤ 140 [N/mm2] | ||

| Sliding speed | ≤ 2.5 [m/s] | Max. PV-value | 2.8 [N/mm² x m/s] |

| Friction value | 0.04 [µ] to 0.12 [µ] | Percentage contact area | > 75 [%] |

| MATERIALS | |||

| Support material | Steel copper-plated or tin-plated | Sliding layer | CuPb10Sn10 |

| TOLERANCE DETAILS | |||

| Housing Ø | H7 | Shaft tolerance | f7 to h8 |

| Bushing inner-Ø after mounting | H9 | ||

| SHAFT MATERIAL | |||

| Steel, hardened or untempered | |||

| Surface roughness ≤ Ra 0.8 | |||

| PROPERTIES | |||

| For high load capacity and oscillating movement, as well as for rough operation and temperature load. Long-run lubrication because of lubricant storage. | |||

| RANGE OF APPLICATION | |||

| Track rollers, construction machines, crane construction, agricultural machines (impact loading) | |||

| MAINTENANCE | |||

| It is a low-maintenance bushing material. An initial greasing during installation is necessary, after that periodic greasing with oil or grease is mandatory. | |||

| MOUNTING ADVISE | |||

| Housing | Mounting bevel min. 1.5 mm x 15-45° | ||

| Shaft | Mounting bevel 5 mm x 15°, edges rounded | ||

| The application of an adequate force fitting mandrel is advisable. Grease lubrication of the outer surface may be necessary when mounting. | |||

| Gluing | Adhesive should not contact the sliding surface! | ||