JIAXING VIIPLUS INTERNATIONAL TRADING CO.,LTD |

|

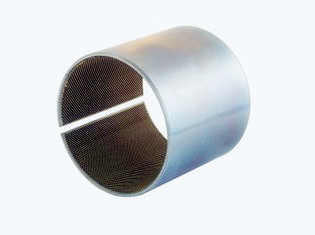

Wrapped bushing with PTFE sliding surface Special manufacturing

Upon request, we can offer inch-sizes, special lengths, bearings

acc. to drawing and various PTFE-layers for different areas of use as well as different backings in bronze

or stainless steel etc.

Corrosion-Resistant Materials Bearings--Stainless Steel T316, Sintered for increased lubricity and hardness

Thrust washers and sliding plates (sheets) If a bore is made,

always operate from the sliding surface towards the steel surface.

This is to prevent the three layers from dividing.

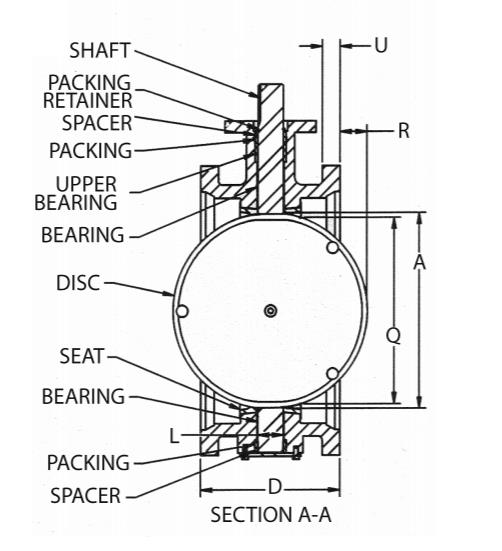

VIIPLUS VALVE bearings that are of the self-lubricating type which provide strength

and low friction for easy operation and lifetime service. No

special periodic maintenance is needed.

The permanently lubricated upper and lower bearings require no

maintenance, and are designed for horizontaland/or vertical shaft

loading.

The bearings provide strength and low friction for easy operation

and long service life.

Valves Bushings are available. Please contact VIIPLUS.

Valves shall be furnished with replaceable Stainless Steel, sintered sleeve type bearings conforming Bearings shall be of sintered, oil impregnated type 316 stainless stell bushings

TEX Bushing,Customized Bushing , Fiber Bush

Hinge pins shall be 304 Stainless Steel rotating in bronze bearings

Stainless steel fabric bushings,this kind of bushings widely used in valve,oil, chemistry, metallurgy.It has flexible bearings, no maintenance, low installation accuracy, good shock absorption and impact resistance. Low noise characteristics, and due to the high strength of the fiber material and the support of the steel back, it has the unique advantage of high load capacity. In general sports, it is advisable to maintain proper clearance between the inner hole and the shaft. The size of the gap can be referred to the DU type product. The outer diameter of the bearing and the seat hole are generally interference fit. The interference can also be referred to the DU type product.

Metal matrix fabric composite sheet has more flexibility than general rigid bearings due to the 0.25mm thickness of fiber cloth lubrication layer. In some low-speed rocking motions, the bearing inner hole and the pin shaft can be used without gaps or even interference. Cooperate, this can better exert its shock absorption and low noise performance; such bearings are mainly used in low-speed, heavy-duty oil and grease lubrication, and can also be used in oil-free lubrication.

1. Press both upper and lower bearings into the valve body.

2. Install lower stem packing and lower spacer. Install cover plate with cap

screws and washers.

3. Install upper bushing, upper packing, and upper spacer into

valve body top stem hole.

4. Install packing retaining ring onto groove on valve stem.

5. Install disc into valve seat. This will require that a lubricant

such as silicone oil or grease be

applied to the stem hub areas of both the disc and seat.

6. Install stem into valve body top stem hole (operator top plate

side). The stem should be

installed so that its milled flat aligns with the disc torque plug

hole.

7. Torque the plug down through the disc and against the milled

flat on the stem.

| Di (mm) | Do (mm) | ST (mm) | dD (mm) | dP (mm) | Ha max. (mm) | Ha min. (mm) | |

| WC08DU | 10 | 20 | 1.5 | 1.2 | 0.95 | ||

| WC10DU | 12 | 24 | 1.5 | 1.75 | 18 | 1.2 | 0.95 |

| WC12DU | 14 | 26 | 1.5 | 2.25 | 20 | 1.2 | 0.95 |

| WC14DU | 16 | 30 | 1.5 | 2.25 | 22 | 1.2 | 0.95 |

| WC16DU | 18 | 32 | 1.5 | 2.25 | 25 | 1.2 | 0.95 |

| WC18DU | 20 | 36 | 1.5 | 3.25 | 28 | 1.2 | 0.95 |

| WC20DU | 22 | 38 | 1.5 | 3.25 | 30 | 1.2 | 0.95 |

| WC22DU | 24 | 42 | 1.5 | 3.25 | 33 | 1.2 | 0.95 |

| WC24DU | 26 | 44 | 1.5 | 3.25 | 35 | 1.2 | 0.95 |

| WC25DU | 28 | 48 | 1.5 | 4.25 | 38 | 1.2 | 0.95 |

| WC30DU | 32 | 54 | 1.5 | 4.25 | 43 | 1.2 | 0.95 |

| WC35DU | 38 | 62 | 1.5 | 4.25 | 50 | 1.2 | 0.95 |

| WC40DU | 42 | 66 | 1.5 | 4.25 | 54 | 1.2 | 0.95 |

| WC45DU | 48 | 74 | 2 | 4.25 | 61 | 1.7 | 1.45 |

| WC50DU | 52 | 78 | 2 | 4.25 | 65 | 1.7 | 1.45 |

| WC60DU | 62 | 90 | 2 | 4.25 | 76 | 1.7 | 1.45 |

TEX bearing use the PTFE fibres fabric and aramid fiber overlay on metal backings,the fabric have very high load capacity and high accuracygood run with low speed and heavy friction superior performance

Polytetrafluoroethylene fiber PTFE/Kevlar

VIIPLUS TEX ptfe fiber metal base self-lubricating bearing is a self-lubricating composite bearing material made of high-quality low-carbon steel plate, bronze plate or stainless steel plate as the matrix, with the woven fabric of ptfe fiber as the friction surface layer.

The two are rolled into sliding bearing by means of a solid bond of structural adhesive.In order to guarantee the bonding strength between ptfe fiber and metal sheet, the woven fabric is made of special ptfe filament and aramid filament.

The bearing has the characteristics of high bearing capacity, good wear resistance, suitable temperature, wide range of medium, simple structure, compact size and good stability.

Polytetrafluoroethylene (ptfe) is a kind of self-lubricating material with excellent performance.But the wear resistance is poor because of the low strength.At present, most of the fibers or other fillers are

used to improve the wear resistance, the effect is very limited.And polytetrafluoroethylene fiber has tensile strength 15 times higher

than pure polytetrafluoroethylene resin, to make up for the lack of

this aspect, wear resistance is greatly improved, at the same time, the fiber also avoids the occurrence of cold

flow phenomenon of polytetrafluoroethylene resin.

Polytetrafluoroethylene fiber metal base self-lubricating bearings

are divided into steel base, copper base and stainless steel base

three.

Maximum load pressure: 180Mpa

Friction factor: 0.03~0.20

Operating temperature range: -90 ° C ~ 180 ° C

Fiber bearing can be used in seawater, gasoline, hydraulic oil, engine oil, kerosene, lubricating oil, weak acid, ammonia water, liquid nitrogen, toluene, washing fluid and other media.

Fiber bearing is the most suitable for high load, low speed, oil film can not be maintained or formed, can not use lubricants, impact load is large, corrosion resistance, swing and other conditions of the use of the bearing, the specific application is as follows:

Hydropower station: turbine water guide mechanism, ball valve, butterfly valve;

Heavy lift systems for trucks, tractors, forklifts and related equipment, such as rocker arm bushing, etc.;

Steering system, braking system and connecting rod fulcrum of clutch of trucks, buses and agricultural tractors;

A motor steering system, such as a motor pivot, is installed externally at the stern;

Butterfly valve and ball valve, bearing comply with NSF drinking system structure parts health standards;

Food machinery, textile machinery, printing machinery, tobacco machinery, packaging machinery, medical equipment and so on;

Supporting bearings for Bridges, pipelines and other structures;

Lifting machinery, especially the main boom, moving boom, foot fulcrum and other parts of the fulcrum can not be lubricated.

Strong impact load resistance, no "crawling" phenomenon, smooth operation;

High wear resistance, good corrosion resistance, no cold flow phenomenon;

Good dimensional stability (no expansion in water), non-conductive, non-magnetic;

Bearing is thin wall structure, light weight, small volume, suitable for compact design;

Low friction woven fabric oilless bearing VSB-36 TEX is widely used in high temperature production lines, construction machinery, automobile chassis parts, ball valves, butterfly valves, pumps and chemical industries and high-speed trains and other heavy low and cannot refuel occasion etc.

This new material use the PTFE fibres fabric overlay on metal backings.

The fabric has very high load capacity and much longer operating life compared with conventional 3-layer bushes.

The metal can be Carbon steel , Stainless steel, Bronze etc.

TEX Bushing,Customized Bushing,Fiber Bush & Low Friction Woven Fabric Oilless TEX Bearing

Plain Bearings and Sleeve Bearings Self-Lubricating Bearings, Liner Type Non-Metallic woven Stainless Steel 316 with PTFE fabric

Stainless steel 316 and steel-base polytetrafluoroethylene aramid fiber braid bearings are self-lubricating materials with wear-resistant fibers as the main surface material.The product has low friction coefficient, good bearing capacity, abrasion resistance and self-lubrication performance, mainly used in various high-grade valves and go-kart.

Max. load | Static | 350N/mm2 |

Dynamic | 180N/mm2 | |

Max. speed | Dry | 0.5m/s |

Lubrication | >1m/s | |

Max. PV (Dry) | Short-time | 3.6N/mm2*·m/s |

Continuous | 1.8N/mm2*·m/s | |

Temp. | -50℃~+250℃ | |

Friction coefficient | 0.03~0.20 | |

Thermal conductivity | 42W (m·k)-1 | |

Coefficient of thermal expansion | 11*10-6k-1 | |

Polytetrafluoroethylene (PTFE) fiber fabric self-lubricating composite material is a new kind of solid self-lubricating material,PTFE fiber fabric retains the low friction coefficient of PTFE material at the same time, and has a high mechanical strength.Therefore, as the lubrication layer between the inner and outer rings of joint bearing, it is widely used in aerospace, automobile, large machinery and other fields.In this paper, PTFE fiber and Kevlar fiber were used as raw materials to weave PTFE fiber fabric by weaving machine. After the surface treatment of sodium naphthalene complexate solution, the self-lubricating composite material of PTFE fiber fabric was prepared by phenol-epoxy adhesive and bonding curing treatment of 45# steel.The friction coefficient and wear amount of PTFE fiber and the effect of surface treatment on the friction properties of composites were measured by friction and wear testing machine.The friction surface was characterized by scanning electron microscopy and the friction mechanism was analyzed.The interlining materials of woven fabric and finished fabric are compared and analyzed.The results show that the surface treatment with sodium naphthalene complex solution can strip the F element from the surface of PTFE fiber fabric, enhance its bonding strength with metal, but also reduce the wear resistance of PTFE fiber fabric to a certain extent.And the shorter the surface treatment time is, the smaller the reduction of wear resistance will be.In addition, the surface treatment of sodium naphthalene complex solution has little effect on aramid fiber and Kevlar fiber.After surface treatment for 5min, the friction surface of the sample produced more debris and abrasive wear.The higher the content of PTFE fiber in the self-woven fabric, the better the anti-wear performance of the fabric. For the fabric with 30% fiber content, the higher the friction speed is, the higher the friction coefficient is.On the contrary, for fabrics with 80% PTFE fiber content, the higher the friction speed, the lower the friction coefficient.

Stainless Steel316+PTFE/FABRIC

Apply to the oil or fuel work harder parts,wear resistance,low coefficient of ftiction,long life:good overall performance.Apply to the oil or fuel work harder parts,wear resistance,low coefficient of friction,long life;good iverall perfotmance.

It is of oil resistant, acid resistant, alkali resistant and seawater resistant, more over, there is no lead in the PTFE surface layer and so is particularly fit for application in food machinery, alkali flow meters, pumps motion elements in pharmaceutical machines, printing machines chemical engineering machines and other ocean industry. The bushing is a triple layers composites one, the base material is stainless steel back and a film of heat resistant power filled PTFE being calendered onto the sintered spherical bronze interlayer.

· Cylindrical bushes

· Flanged bushes

· Sliding plates

· Thrust washers

· Flanged washers

START YOUR PROJECTWITH AN APPLICATION ENGINEER

VIIPLUS SLDING BEARINGS FOR OFFSHORE PLATFORMS AND OIL & GAS INDUSTRY | VIIPLUS BEARINGS