JIAXING VIIPLUS INTERNATIONAL TRADING CO.,LTD |

|

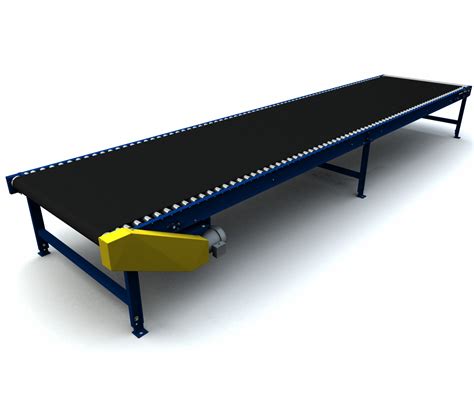

Because of its light weight, low cost and maintenance-free, self-lubricated bearings are widely used in all kinds of fitness and entertainment equipment.Metal-Polymer Anti-Friction Plain Bearings self-lubricating Bearings Cylindrical PTFE for belt conveyor.

Interpret the skill transformation of food belt conveyor Bushing & Bearings

China's agricultural products deep processing industry to transport

network belt not only expect quantity, stainless steel network belt and more technology water steep dry bearing steep

function, quality.This points out a bright way for the development

of China's transport network and belt industry.

Plastic bearing seat is indispensable in the transmission of food

belt transport machinery and equipment important components, in the

production and transport operations can be better forward transport

equipment transmission power, and then play a role in reducing

energy consumption.In the process of the development of modern

sliding bearing technology and skills, in order to make the bearing

seat very good forward bearing ability, China has made relatively excellent innovation in terms

of the function and material of the bearing seat, and adopted

engineering plastics to make the bearing seat.Plastic bearings have

been tested to be more rigid and rigid than steel bearings, so they

are used in different types of food belt conveyors.

Low power consumption of belt conveyor accessories.As there is no relative movement between the material and the

delivery belt, not only the operation resistance is small, but also

the wear and breakage of the cargo are small, the yield is high.All

these are advantageous to reduce production cost.

Belt conveyor accessories transport line habitual strong and

active.The length of line composite bearing depends on the need.It can be as short as a few meters and as long

as more than 10km.They can be installed in small tunnels or over

ground traffic disturbances and risk areas.

Belt conveyor accessories can be very flexible to receive material

from one or more points depending on the skill flow.It can also be

discharged to multiple points or sections.Belt conveyor accessories

become a primary transport trunk when they are delivered together

at several points to the belt feeder (such as the conveyor

accessories under the coal bin of the coal preparation plant) or

along the belt conveyor accessories at any point in the length

direction of uniform feeding equipment.

Belt conveyor accessories can be used to pick up materials in the

roadway below the coal yard pile and, when needed, mix different

materials from different piles.Materials can be simply unloaded

from the accessories head of the conveyor, or can be unloaded at

any point in the length direction of the conveyor belt by the

plough type unloading device or by the moving unloading

truck.According to the needs of transportation skills, it can be a single unit, or more than one set of transport

equipment or other transport equipment to form a horizontal or skew

transport system to meet the needs of different types of operation

lines.

Food belt delivery machinery traditional plastic bearings are based on a single engineering plastic material.Over the years, the use of habits of a wider range of planning

needs, especially food, medicine, drinks and other operations on

the production environment, equipment reliability, equipment

operation power needs to continue to advance, a variety of

composite plastic bearing seats play an increasingly important

role.

Plastic bearing base by adding composite fiber filler, can reach high compressive resistance, heat resistance and creep resistance, composite fiber itself has

excellent resistance function;Participating in solid grease, the

selected constituent material and composite fiber are combined to

help reduce resistance.Plastic bearing housing has excellent

resistance function, but also has high precision, low thermal expansion rate, low water absorption

rate, high compressive stress, creep resistance high-grade

characteristics.

Plastic bearing seat production material, as a new type of high

molecular material, the resistance coefficient is small, from the

wear loss property, plastic bearing seat production material than

the usual carbon steel material bearing seat more wear resistant,

but also has the characteristics of self-lubrication.

The condition of self-lubricity is that the cohesion between

molecules should be small, the atoms in the molecular structure are

placed symmetically, other lubrication functions and lubrication

conditions.Plastic bearing seat surface strength ratio high and

very lubrication, basically do not appear tension, with excellent self-lubrication function and low resistance coefficient,

on the basis of adhering to the traditional advantages of plastic

bearing seat, can be used in production operations compared to fine

or high speed operation of the transport operation.

Plastic bearings can work well in alkaline environments, but not in

corrosive environments rich in acid.The rigidity of plastic bearing

seat is large, the hardness is high, even in the operating

environment with low temperature contrast, the strength of impact force is also high.

The self-lubricating bearings are light, cost-effective and maintanence free, So they are widely used to various kinds of body fit equipment and .

ROLLED DRY SLIDING BEARINGS (PTFE)

Steel + Bronze Powder + PTFE/Fibre(DU)

Wrapped PTFE Lined (maintenance-free), self lubricated plain or flanged bearings, thrust washer and strip, Carbon steel shell with sintered bronze layer filled with PTFE

VSB-10 Self-Lubricating Multilayer Composite Bushing

Bushing material suitable for lubricated applications

self-lubricating bushings offer very good wear and low friction performance over a wide range of loads, speeds and temperatures in dry running conditions

Anti-friction bearing suitable for linear, oscillating and rotating movements

Material is designed to operate without supplemental lubrication and will perform excellent when lubrication is present. Low friction, low wear rate, good sliding characteristics and very low absorption are a few of the features of this material. VSB-10 bushings will support rotary, linear and oscillating motion.

1. PTFE/Fibre mixture thickness 0.01~0.03mm. It is the contact surface for the

rotating shaft. Minute partides of the PTFE layer and the sintered bronze material combine to create a solid

lubricant film, which coats the shaft.

2. Sintered bronze powder thickness 0.20*0.35mm,A special composition of powdered

copper is thermally fused to the steel backing. This contact layer

acts as an anchor for the PTFE layer and conducts the thermal build

up away from the bearing surfaces.

3. Low-carbon steel backing. Setting the foundation of the bushings, the steel

back provides exceptional stability, load carrying and heat

dissipation characteristics.

Technical parameters |

|

|

|

|

|

Maximum load | Static load | 250N/mm2 | frictional coefficient | 0.03~0.20 | |

Low speed | 140N/mm2 | ||||

Rotation, swing motion | 60N/mm2 | maximum line velocity | dry friction | 2m/s | |

fluid lubrication | >2m/s | ||||

Maximum PV value (dry friction) | Intermittent operation | 3.6N/mm2*m/3 | Thermal conductivity | >2m/s42W(m*K)-1 | |

Long-term operation | 1.8N/mm2*m/3 | ||||

Operating temperature | -195℃~+280℃ | linear expansion coefficient | 11*10-6*K-1 | ||

Carbon Steel + Copper Powder + (PTFE + Pb + Filler)

STRUCTURE AND COMPOSITION

· Metal-Polymer Composite Self-lubricating Bushing Material

· Steel Back + Porous Bronze Sinter +

· PTFE + Lead

OPERATING PERFORMANCE | |

Dry | Very Good |

Oil lubricated | Good |

Grease lubricated | Fair |

Water lubricated | Fair |

Process fluid lubricated | Fair |

AVAILABILITY

Bearing forms available in standard dimensions

· Cylindrical bushes

· Flanged bushes

· Thrust washers

· Flanged washers

· Sliding plates

TYPICAL APPLICATIONS

START YOUR PROJECT With an Application Engineer

DU Bushing, DU Bearing, Line Bearing, Ptfe Coated Bushing, DX Bush, DX Bearing

VIIPLUS Provide all types of electronic samples for customers,Metal-Polymer Composite Bearings Catalog!

Bushings,Lubricated Bearings,Composite Bearings,Metal Bearings,Compressor Bearings,Metal-polymer,Filament Wound,Plain Bearings,Flange Bearings,Polymer Bearings,Flange Bushings,Pump Bearings,Flanged Bushes,Thrust Plates,Industrial Bearings