JIAXING VIIPLUS INTERNATIONAL TRADING CO.,LTD |

|

Rolling bearing is a kind of rolling bearing, which is based on

high quality cold-rolled steel plate and sintered with porous

spherical bronze powder in the middle, and then sintered with a

mixture of PTFE and fiber on the surface of porous spherical bronze powder, and

rolled.

This product has the characteristics of small friction coefficient,

abrasion resistance, good corrosion resistance and

self-lubrication.Using this product can reduce the cost, reduce the

mechanical volume, avoid the phenomenon of shaft biting and reduce

the mechanical noise and other characteristics.

This product has been widely used in various mechanical sliding

parts, such as printing machine, elevator, textile machine, tobacco

machine, fitness machine, hydraulic conveyor, micro-motor, solenoid

valve, automobile and agricultural and forestry machinery.

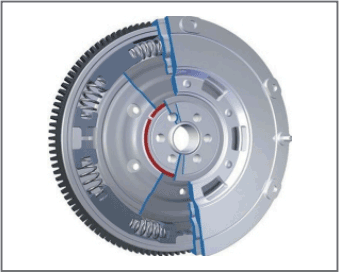

Self-lubricating bearing, moving it against the clutch diaphragm spring fingers. ... Dual-Mass Flywheel prevent engine torque spikes from exceeding engine and ... self-adjusting cable systems, are in constant contact with the diaphragm spring fingers.

self-lubricating materials meeting RoHs environmental requirement in automobile field. Oilless bearings are installed at over 30 parts of an automobile, such as door hinge, engine hood hinge, trunk hinge, windscreen wiper, shock absorber, steering system, pedal assembly, seat angle regulator and starting motor.

Self-lubricating bearing widely use in dual-mass flywheel.

A dual-mass flywheel is a rotating mechanical device that is used to provide continuous energy in systems where the energy source is not continuous, the same way as a conventional flywheel acts, but damping any violent variation of torque or revolutions that could cause an unwanted vibration. The vibration reduction is achieved by accumulating stored energy in the two flywheel half masses over a period of time but damped by a series of strong springs, doing that at a rate that is compatible with the energy source, and then releasing that energy at a much higher rate over a relatively short time.

What is a Dual Mass Flywheel? | Metal Polymer Composites Plain Bearing | Dual mass flywheel repair bush solutions

DU Composite slide Bearing, SF-1 bushing,SF-1 bush beairng,DP4 bushing

Composite dry sliding bearings are primarily used for bearing arrangements where heavy loads have to be supported and where rotational or oscillating movements are relatively slow.

Because of their good sliding properties and compact design, these

plain bearings are particularly suitable for bearing arrangements

where:

Maintenance-free operation is a prerequisite

There is a risk of lubricant starvation

Lubricants cannot be used or are forbidden

Space is limited.

Maintenance-free operation

No lubrication required (PTFE composite)

Initial lubrication required (POM composite)

Minimum wall thickness, minimum space requirements

Accommodation of heavy loads

Wide range of temperatures

Good sliding properties

Virtually no stick-slip

High wear resistance

Double mass flywheel structure is very simple, the first mass

flywheel and engine crankshaft output flange connected, the second

mass flywheel through a self-ubricating bearing mounted on the

first mass flywheel, the second mass flywheel with clutch

cover.There is a shock absorber connection between the two

flywheels.

ROLLED DRY SLIDING BEARINGS (PTFE)

Steel + Bronze Powder + PTFE/Fibre(DU)

Wrapped PTFE Lined (maintenance-free), self lubricated plain or flanged bearings, thrust washer and strip, Carbon steel shell with sintered bronze layer filled with PTFE

Double Mass Flywheel Repair self-lubricating Bearings

A passenger car with at least 30 parts with self-lubricating bearings. Shock absorbers, brake systems, pedal assembly, seat adjustment systems, door hinges, air conditioning, air conditioning compressors, secondary air valves, fuel pumps, starter motors, gearboxes, steering pumps, Luggage hinges, hood hinges, wiper and so on. At the same time, in various types of commercial vehicles and trucks are also widely used in a variety of self-lubricating bearings, including the engine connecting rod, gearbox, balance shaft and other parts.

In view of the different characteristics of different parts of the car, VIIPLUS developed different self-lubricating sleeves applicable to different parts. Such as: special collar up tight round collar, shock absorber, shock absorber and piston guide assembly, transmission shaft sleeve and sleeve gasket, seat adjustment system, door hinge hinge axle sleeve and trunk, wiper collar, air conditioning compressor shaft sleeve, start the motor shaft sleeve, power steering pump bearing bushings, steering system and brake system and pedal assembly shaft sleeve, etc.

Bushing material suitable for lubricated applications

self-lubricating bushings offer very good wear and low friction performance over a wide range of loads, speeds and temperatures in dry running conditions

Anti-friction bearing suitable for linear, oscillating and rotating movements

Material is designed to operate without supplemental lubrication and will perform excellent when lubrication is present. Low friction, low wear rate, good sliding characteristics and very low absorption are a few of the features of this material. VSB-10 bushings will support rotary, linear and oscillating motion.

1. PTFE/Fibre mixture thickness 0.01~0.03mm. It is the contact surface for the

rotating shaft. Minute partides of the PTFE layer and the sintered

bronze material combine to create a solid lubricant film, which

coats the shaft.

2. Sintered bronze powder thickness 0.20*0.35mm,A special

composition of powdered copper is thermally fused to the steel

backing. This contact layer acts as an anchor for the PTFE layer

and conducts the thermal build up away from the bearing surfaces.

3. Low-carbon steel backing. Setting the foundation of the bushings, the steel back provides

exceptional stability, load carrying and heat dissipation

characteristics.

Carbon Steel + Copper Powder + (PTFE + Pb + Filler)

· Metal-Polymer Composite Self-lubricating Bushing Material

· Steel Back + Porous Bronze Sinter +

· PTFE + Lead

| Sliding layer |

OPERATING PERFORMANCE | |

Dry | Very Good |

Oil lubricated | Good |

Grease lubricated | Fair |

Water lubricated | Fair |

Process fluid lubricated | Fai |

Max. load | Static | 250N/mm2 |

Dynamic | 140N/mm2 | |

Max. speed | Dry | 2m/s |

Lubrication | >2m/s | |

Max. PV (Dry) | Short-time | 3.6N/mm2*·m/s |

Continuous | 1.8N/mm2*·m/s | |

Temp. | -195℃~+280℃ | |

Friction coefficient | 0.03~0.20 | |

Thermal conductivity | 42W (m·k)-1 | |

Coefficient of thermal expansion | 11*10-6k-1 | |

Bearing forms available in standard dimensions

· Cylindrical bushes

· Flanged bushes

· Thrust washers

· Flanged washers

· Sliding plates

1: load P: the greater the load, the shorter the service life of

the bearing;Under no circumstances shall the maximum load exceed

the theoretical maximum allowable load.

2: speed V: the higher the speed, the shorter the service life of

the bearing;Under no circumstances shall the maximum sliding speed

exceed the theoretical maximum allowable value.

3: PV value: the working life of the bearing depends on the PV

value, that is, the product of the actual load P and the sliding

speed V. The smaller PV value is, the longer the bearing life is.

4: temperature: the life of the bearing also depends on the

temperature when the bearing is in use, the higher the temperature,

the shorter the life of the bearing, so in the design and selection

should try to consider the heat dissipation characteristics of the

relevant parts.

5: surface roughness of the grinding parts: alloy steel or hard

chromium plated shaft is used for the grinding parts. When the

surface roughness Ra=0.4-0.63, the service life of the bearing can

be significantly improved.

6: other factors such as bearing design, lubrication conditions,

etc

Widely used in hydraulic and pneumatic industries, forging machine tool industry, plastics machinery industry, lifting and handling machinery, port machinery, office, fitness machinery, textile machinery, food packaging, filling machinery, chemical machinery, printing and packaging, paper making machinery, automobiles, railways Steam locomotives, shipbuilding industries, presses, metallurgical machinery, construction machinery, etc.