Roller forming methods divided into two types whole forging and casting, when casting, the roller has low-density and structure is rough but economical, Forging is shaping depending on air beating gravity, thus very substantially increased roller density, due to high density, it has effectively improved the wear resistance and extended service life.

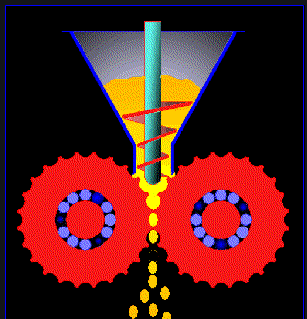

Briquette Machine roller making

Roller material: 65Mn/9Cr2Mo /High chromium alloy

We have different roller material to choose when briquetting

different materail.

The diameter of roller based on briquette machine model.

The briquette shape can be oval, oblate and pillow shape etc.

The size of final briquette between 20-75mm

Briquettes information

The final briquette out from our briquette machine can be oblate, pillow and oval shape.

The briquette size between 20-75mm.

Please confirm briquette shape and size before briquette machine making.

Packing &Shipping

Packing Details : All products will be processed to be rustproof and moisture proof before delivery.

20GP container or 40GP container

Equipment is packed with plastic wrap or steel case, depends on

machine weight.

Motro is packed with steel case or wooden case. Control panel is

packed with steel case.

Loading container in factory.

Delivery Details : 15-25 days after confirming order,detail delivery date should be decided according to production season and order quantity.