Anhui Liyuan CNC Blade Mold Manufacturing Co., Ltd. |

|

Verified Suppliers

|

|

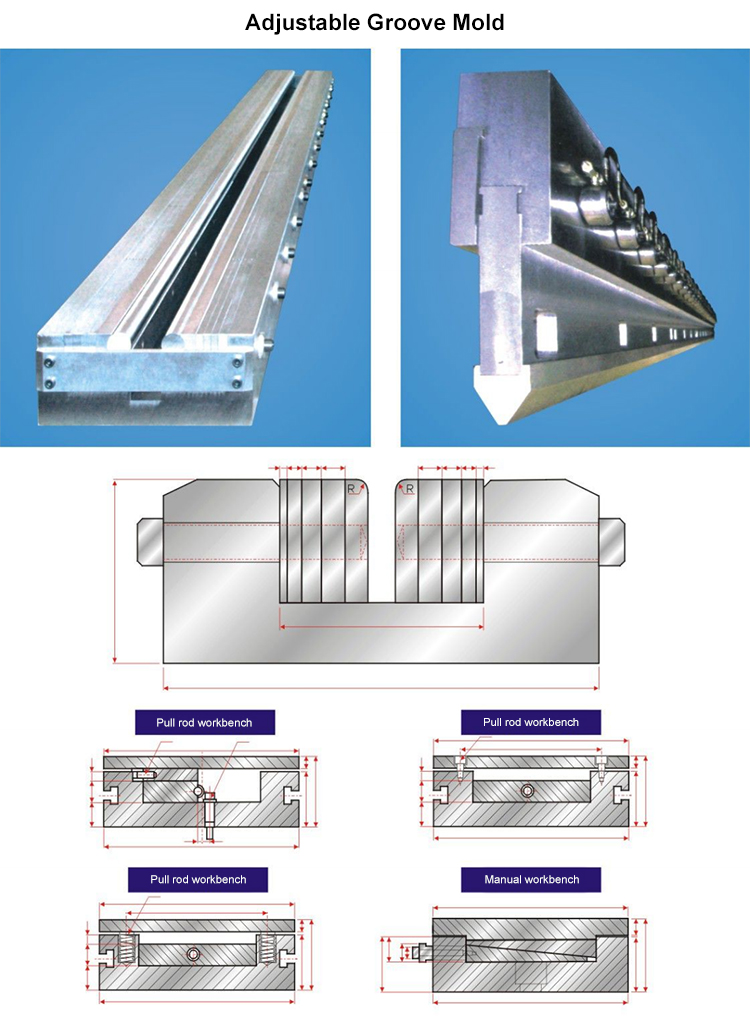

Long-durable sheet metal forming press brake die tools hydraulic press brake punch and die press brake bending dies

Product Name | Press Brake Bottom Die |

Material | 42CrMo |

Color | Metallic |

Size | Customizable Sizes |

Hardness | 45-50HRC |

Forming Method | Stamping |

Application | Used on press brake machine |