Zhangjiagang Jiayuan Machinery Co.,Ltd. |

|

Breifs on Priduct

a. This type of small juice filling machine is for the juice production line.

b. Heavy duty 304 stainless steel welded frame, 316 stainless steel hygienically processed filling nozzles and capping heads.

c. Siemens PLC system along with Omron photoelectric sensor make this machine smart.

d. 7-inch touch screen tames this steel beast perfectly.

f. The filling nozzle stroke is adjustable to the different volumes of bottle.(200ml-2500ml)

g. Faster and more effective product and bottle changeover reduces your product losses.

h. Hygienic design for easy resource-saving sanitizing. juice bottling machine

Having been proved by certificates like SGS, CE.

Detailed Description and Images

mall juice filling machine

Hot Filling: In order to avoid any kind of shape change while doing hot filling, The bottles will be grabbed at their necks. Once bottles in the right position, those filling nozzles move down half inside the bottles. The outlet channel of the filling valve opens up, and the hot liquid(tempereture ranges from 85 to 95 degrees celsuis) flows down. As the bottles getting filled up, the inlet channel opens up to allow the superfluous amount to flow back. This whole process makes sure bottles get fully filled.

The temperature of the liquid is monitored, and the backup recirculation system allows the liquid to flow back from the filling station once the tmperature drops down blew the pre-set.

| a. Plier-like clutches could easily hook up bottle's neck without doing any damage. b. Neck-catching design makes it fit bottles with a large range of size. c. Made of stainless steel where durability comes from. |

a. 316 stainless steel made filling nozzles, sanitarily reliable and durable. b. Nozzle stroke can be adjusted through a certain range, making the filler variably fit different bottle volumes(200ml-2500ml). c. Stabilizer contacting bottle's bulk down below is made of polymer materials. d. Enhanced by the photoelectric sensor, no bottle no fill. e. Bulged constituents make nozzle easy to clean. |  |

| a. Made of stainless steel 316, ensuring durability. b. Caps are put onto the bottles by the cap sorter upstream c. Enhanced by the photoelectric sensor, no bottle no cap. d. Easily adjustable cap torque settings make it smooth to operate. e. Simple and easy-to-change parts facilitate the adjustment between different sizes of bottles and caps. |

Quality Assurance

Company Info

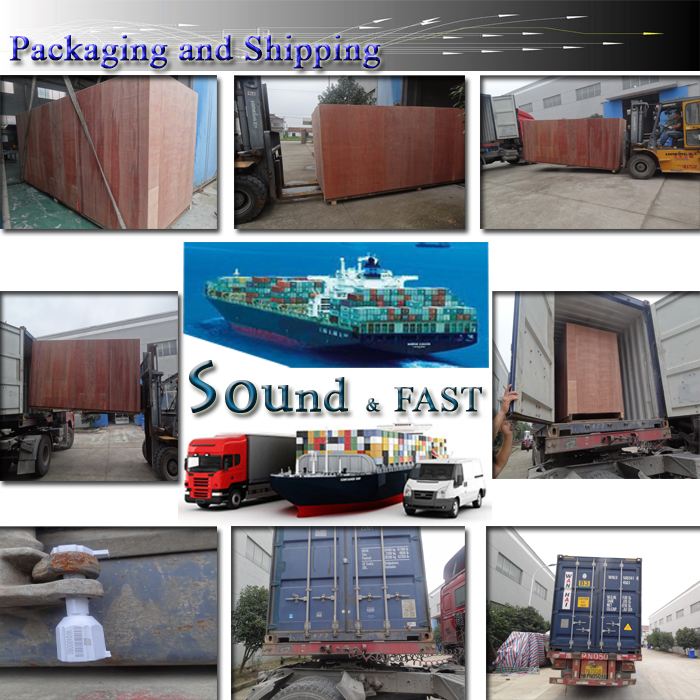

Packaging and Shipping

Our Service

.