Zhangjiagang Jiayuan Machinery Co.,Ltd. |

|

Why our machine is better than other similar machines

1. Each water filling machine element tha contacts with the liquid is made of high quality Stainless steel 304, if needed, SS 316 is also available.

2. The water filling machine adopts bottle neck holding transmission technology to realize fully automatic rinsing, filling and capping.

3. Most elements of the electrical system use famous international brand, such as Mitsubish, Omron brand.

4. The water filling machine obtain the advantages of good abrasive resistance,high stability,low failure rate, etc. The quality of the equipments reaches the international advanced level.

5. Advanced technologies, human-machine interface touch screen and PLC program control are adopted in this machine.

6. Nozzles in the grab can guarantee the complete wash of the interior of the bottle..........

7. Easy to operate, save the cost of workers..

Carbonated beverage rising filling capping 3 in 1 machine

This automatic beverage filling machines/beverage automatic filling machine/beverage processing machinery , combined with rinsing, filling and capping. It is innovated and designed in the requirement of

still pure water and mineral water, on the bases of introducing, digesting and absorbing advanced technology from Germany and Italy.

Technical parameter

| odel | DCGF 16-12-6 | DCGF 18-18-6 | DCGF 24-24-8 | DCGF 32-32-10 | DCGF 40-40-12 | DCGF 50-50-15 |

| Washing No | 16 | 18 | 24 | 32 | 40 | 50 |

| Filling No | 12 | 18 | 24 | 32 | 40 | 50 |

| Capping No | 6 | 6 | 8 | 10 | 12 | 15 |

| Production Capacity(500ml) | 3000BPH | 5000BPH | 8000BPH | 12000 BPH | 15000 BPH | 18000 BPH |

| Install Capacity(KW) | 3.5 | 4 | 4.8 | 7.6 | 8.3 | 9.6 |

| Overall size | 2450×1800×2400 | 2650×1900×2400 | 2900×2100×2400 | 4100×2400×2400 | 4550×2650×2400 | 5450×3210×2400 |

Machine pictures

inner look

washing

filling

capping

electrical system

3. The working process

The bottle enters into the rinsing part of three-in-one machine through air conveyor. The gripper installed on the rotary disk catches bottle and turns it over 180 degrees and makes the bottleneck face ground. In the special rinsing area, the nozzle on the gripper sprays juice to rinse bottle inwall. After rinsing and draining, the bottle turns over 180 degrees along the guide rail and make the bottleneck faces sky. Then rinsed bottle is transferred to the filling part through poking bottle starwheel. The bottle that enters into the filler is hold by neck holding plate. The filling valve acted by the cam can realize up and down. It adopts equal pressure filling way. The filling valve opens and begins filling when it moves down and touches thebottleneck, the filling valve move up and leave the bottleneck when it finishes filling, the full bottle is transferred to the capping part through hold neck transition poking wheel. The stop screwing knife holds the bottleneck, keeps bottle upright not rotating. The screw capping head keeps in revolution and autorotation. It can finish a whole capping course including catching, pressing, screwing, discharging through the action of the cam. The full bottle is transferred to bottle outlet conveyor to the next process through starwheel. The whole machine is enclosed with windows, the height of enclosed window is higher than the peak of the 3 in 1 machine, in the bottom of the enclosed window has return air outlet.

about our company

our main production lines:

1. bottling minereal/pure water production line;

2. barrel mineral/ pure water production line

3. bottling carbonated beverage production line (like coca cola);

4. bottling juice production line;

5. canning beverage production line;

6. glass bottle beer production line;

7. milk/tea filling&package line;

8. oil filling&package line;

our two workshops

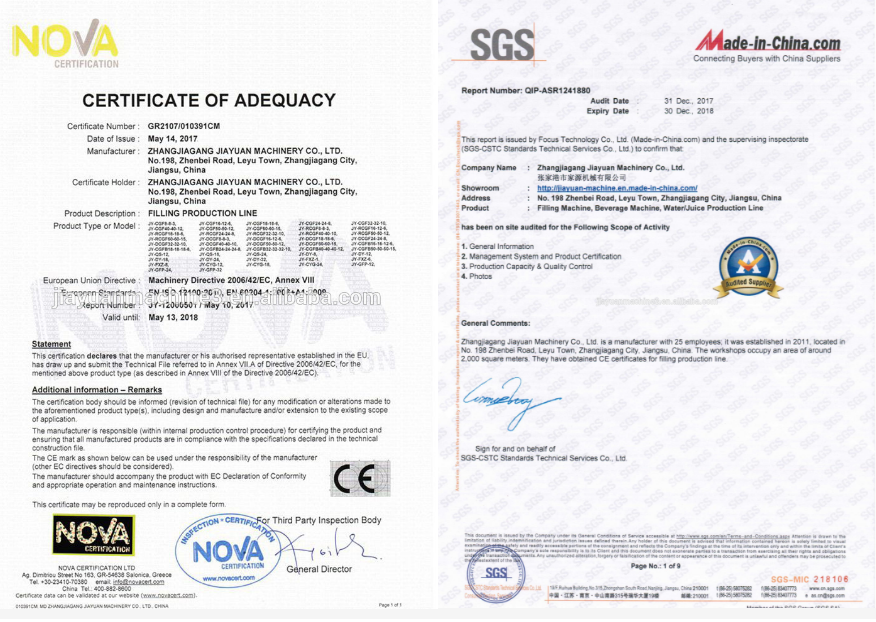

certificate