3500BPH Beverage Drink Filling Machine / Automatic Carbonated /

Soda Water / Line

Product Description:

Products Introduction Of Carbonated Soft Drink Beverage

Filling Botling Machine

1. The whole machine adopts the design of stuck bottleneck suspension

operation mode so that the bottle is stable and reliable under

high-speed operation, and at the same time, the number of changed

parts is greatly reduced, making it more convenient and fast when

changing the bottle type.

2. A new generation of stainless steel flip bottle clamp is adopted

so that the clamp does not contact the upper part of the thread of

the bottle mouth, and a spray head is provided so that the inner

wall of the bottle can be rinsed fully without dead corners.

3. Adopting advanced pressure filling process, the filling is fast,

stable, and accurate.

4. Adopt advanced capping structure for crown cap without any surface

damage of the cap.

5. The whole machine adopts man-machine interface touch screen

buttons, PLC computer control, and is equipped with a cover missing

and overload protection alarm device, which can find and eliminate

faults in time and have a high degree of production automation.

6. The parts in contact with water are made of high-quality stainless

steel, and the main electrical components are all products of

well-known international manufacturers.

Technical Parameters:

Model (BCGF) | 2014/12/5 | 18/18/6 | 24/24/6 | 32/32/8 | 40/40/12 | 50/50/12 |

Washing heads | 14 | 18 | 24 | 32 | 40 | 50 |

Filling heads | 12 | 18 | 24 | 32 | 40 | 50 |

Capping heads | 5 | 6 | 6 | 8 | 12 | 12 |

Capacity (BPH) | 2000 | 3500 | 5000 | 8000 | 12000 | 16000 |

Power(kw) | 2.2 | 3.5 | 4.5 | 6 | 7.5 | 9.5 |

Dimension (mm) | 2400*1600 | 2600*1920 | 3100*2300 | 3800*2500 | 4600*2800 | 5450*3300 |

| *2500 | *2550 | *2800 | *2900 | *2900 | *2900 |

Weight(kg) | 2500 | 3500 | 4500 | 5600 | 8500 | 9800 |

Machines Details :

3 IN 1 Carbonated Soft Drinks Filling Machine

Out Look:

> 304 stainless steel frame

> Tempering Glass window, Clear & no odor

> Excellent start wheel design, easy change over parts

> Machine Base with anti-rust process, ensure the forever

antirust

> All seal where liquid may Leakage & base neck come with

rubber, water proof

> Manual lubrication system

Washing Part:

1)Into bottle way is flat conveyor cooperated with bottle feeding

screw.

2)All 304/316 stainless steel rinse heads, water spray style inject

design, more save water consumption and more clean .

3)304/316 Stainless steel Gripper with plastic pad, ensure minimal

bottle crash during washing

4)304/316 stainless steel washing pump make the machine more

durable .

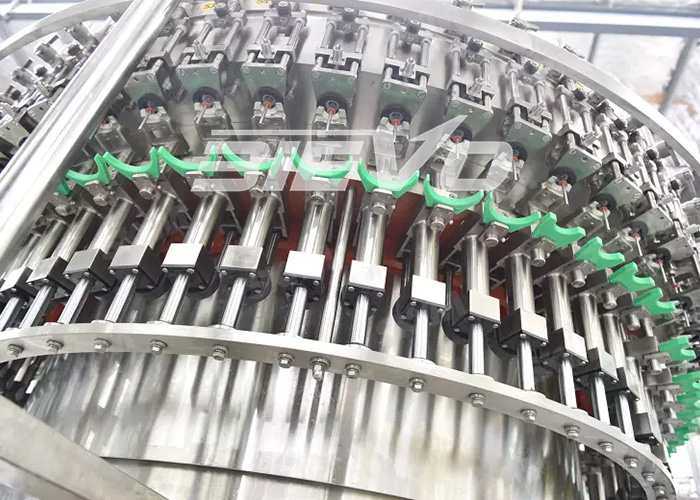

Filling Part :

1) 304/316 Stainless steel high precision filling nozzle2) Filling volume adjustable in fine rank, same liquid level after

filling

3) All 304/316 stainless steel contact parts & liquid tank,

fine polish, no death corner, easy to clean

4) 304/316 stainless steel filling pump

5) Efficient spray nozzle rinse thoroughly and save water for

flushing

6) Air lifting mechanism makes the running more stable and smooth.

Capping Part :

1) Place and capping system, electromagnetic capping heads, with

burden discharge function, make sure minimum bottle crash during

capping

2)All 304/316 stainless steel construction

3)No bottle no capping

4)Automatic stop when lack of bottle

5)Capping effect is stable and reliable ,Defective rate ≤0.2% .

Electrical Brand List |

AC Contactor | SIEMENS (GERMANY) |

Thermal overload relay | |

PLC | SIEMENS (GERMANY) |

Touch Screen | SIEMENS (GERMANY) |

Converter | SIEMENS (GERMANY) |

Power Switch | SIEMENS (GERMANY) |

Intermediate Relay | |

Zhangjiagang City Bievo Machinery Co., Ltd. is located in a

national level development zone - Zhangjiagang Economic And

Technology Development Zone, covering area more than 8,000 square

meters.We enjoy convenient transportation with Shanghai Hongqiao

International Airport and Shanghai Pudong International Airport on

hand.Which accumulated a great number of China's top technologists

in the liquid beverage industry.We have complete system from

designing, manufacturing, installation, training to after

service.Our main product water production line, carbonated beverage

production line . Fruit juice and milk production line ,3 to 5

gallons production line, daily chemical production line and so

on.Plat and tube UHT device, CIP system.All the products are sold

well.We devote ourselves to the development, research and

production of liquid food and beverage filling and packing industry

.

Are you a manufacturer or a trader?

●we are a professional manufacturer for drinking water production

line, carbonated drinking production line, juice production line

and so on!

Welcome to our factory anytime!

● If we can fullfill your request and you interested in our

products, You can visit our website.

● The meaning of visiting supplier, because seeing is believing,

Bievo Machine with own manufacture and developed& research

team, we can send you engineers and make sure your after sales

service.

How to ensure the safety of your funds and timely delivery?

● Through Alibaba letter guarantee service, it will ensure the on

time delivery and the quality of the equipment you want to buy.

● By letter of credit, you can lock the delivery time easily.

● After the factory visit, You can ensure the facticity of our bank

account.

How to guarantee the quality of the machine?

● In order to ensure the accuracy of each part, we are equipped

with a variety of professional processing equipment and we have

accumulated professional processing methods over the past years.

● Each component before assembly needs strictly control by

inspecting personnel.

● Each assembly is in charged by a master who has working

experience for more than 5 years

●After all the equipment are completed, we will connect all the

machines and run the full production line for at least 12 hours to

ensure the stable running in customers' factory.

After-sales service of the machine!

● After finish the production, we will debug the production line,

take photos, videos and send them to customers via mail or instant

tools

● After the commissioning, we will package the equipment by

standard export package for shipment.

● According to the customer's request, we can arrange our engineers

to customers' factory to do the installation and training.

● Engineers and sales managers will form an online and offline

after-sales team to track customer projects.

1. Installation & debugging

After equipments reached the workshop of customer, place the

equipments according to plane layout we offered. We will arrange

seasoned technician for equipments installation, debugging and

testing production at the same time to make the equipments reach

the rated producing capacity of the line.

2. Training

Our company offers technology training to customer. The content of

training is structure and maintenance of equipments, control and

operation of equipments. Training is in the workshop of customer.

Seasoned technician will guide and establish training outline.After

training, the technician of buyer could master the operation and

maintenance, could adjust the process and treat different failures.

3. Quality guarantee

We promise that our goods are all new and not used. They’re made of

suitable material, adopts new design. The quality,specification and

function all meet the demand of contract.

4. After sales

After checking, we offer 12 months as quality guarantee, free offer

wearing parts and offer other parts at the lowest price. After

quality guarantee, we offer technology support and after sales

service. If you could not solve the problems, we will guide you by

phone; if the problems are still can not solve, we will arrange

technician to your factory solving the problems.

![]()