Zhangjiagang City Bievo Machinery Co., Ltd. |

|

8000BPH carbonated soft co2 soda water beverage drink filling machine

Technical Parameters:

Model (BCGF) | 18/18/6 | 24/24/6 | 32/32/8 | 40/40/12 | 50/50/12 |

Washing heads | 18 | 24 | 32 | 40 | 50 |

Filling heads | 18 | 24 | 32 | 40 | 50 |

Capping heads | 6 | 6 | 8 | 12 | 12 |

Capacity (BPH) | 3500 | 5000 | 8000 | 12000 | 16000 |

Power(kw) | 3.5 | 4.5 | 6 | 7.5 | 9.5 |

Dimension (mm) | 2600*1920 | 3100*2300 | 3800*2500 | 4600*2800 | 5450*3300 |

| *2550 | *2800 | *2900 | *2900 | *2900 | |

Weight(kg) | 3500 | 4500 | 5600 | 8500 | 9800 |

Machines Details :

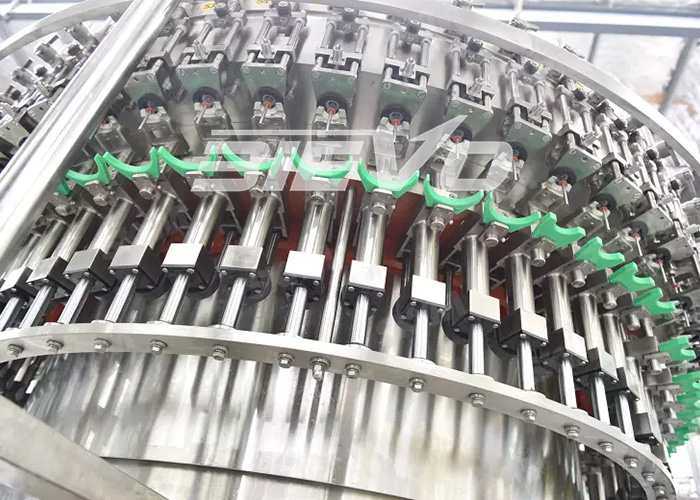

3 IN 1 Carbonated Soft Drinks Filling Machine

Out Look:

> 304 stainless steel frame

> Tempering Glass window, Clear & no odor

> Excellent start wheel design, easy change over parts

> Machine Base with anti-rust process, ensure the forever

antirust

> All seal where liquid may Leakage & base neck come with

rubber, water proof

> Manual lubrication system

Washing Part:

Rotary type bottle washing machine, mainly used to wash bottles for drinking water and other beverage. New bottles go into the machine through air conveyor. Bottles are held by grips and turned over onto washing heads. After washing and drain water, bottles go into filling parts by star wheel. Main structure, protect shell and contact water part of washing part are all stainless steel.

Filling machine adopt German technology, produce by gravity filling and obey to normal pressure filling principle.Main drives adopt mechanical freestanding gear, high efficiency, low noise, long service life, easy to maintain, lubricate well. Frequency converter controls the main motor and makes the machine speed changeable.

Capping machine drives revolved plate by gear. Cap goes out of cap storage by centrifugal effect. At the cap output, there is cap divider. Reverse cap drops into pipes then return to cap storage by air conveyor. Right cap goes into conveyor. The quantity inspected by sensor, capping machine control the cap conveyor. The machine will stop when no caps.

Electrical Brand List | |

AC Contactor | SIEMENS (GERMANY) |

Thermal overload relay | SIEMENS (GERMANY) |

PLC | SIEMENS (GERMANY) |

Touch Screen | SIEMENS (GERMANY) |

Converter | SIEMENS (GERMANY) |

Power Switch | SIEMENS (GERMANY) |

Intermediate Relay | SCHNEIDER (FRANCE) |

Zhangjiagang City Bievo Machinery Co., Ltd. is located in a national level development zone - Zhangjiagang Economic And Technology Development Zone, covering area more than 8,000 square meters.We enjoy convenient transportation with Shanghai Hongqiao International Airport and Shanghai Pudong International Airport on hand.Which accumulated a great number of China's top technologists in the liquid beverage industry.We have complete system from designing, manufacturing, installation, training to after service.Our main product water production line, carbonated beverage production line . Fruit juice and milk production line ,3 to 5 gallons production line, daily chemical production line and so on.Plat and tube UHT device, CIP system.All the products are sold well.We devote ourselves to the development, research and production of liquid food and beverage filling and packing industry .

![]()

Q1: Can you provide more information about this product, and quote

the best price?

A: Sure, please contact us via any methods showed on this page, and

we will send our product catalog, company profile for your

reference.What's more, we will customize detailed offer according

to your specific requirements.

Q2: The price is a little higher than my budget. Can you offer a

better price?

A: The first proposal is preliminary design, as a professional

buyer; pls don't only focus on the price. If you have any question

or request, pls don't hesitate to contact us. Then we will adjust

the configuration and quality according to your request. Your

feedback will lead us to make the proposal to match your request.

Q3: What else need to be paid attention besides price?

A: except for the price, we also need pay attention to quality,

product construction, design principle, configuration of part list,

reasonability, convenience of operation, professional, service and

etc.

Q4: Can you provide turnkey project service?

A: Yes, of course, we can provide the full set of turnkey project

service to you.

Q5: How long of your warranty?

A: Regarding warranty, normally we offer 1 year warranty/3000 hours

warranty, and we also offer lifetime maintenance.

Q6. Do you accept OEM order?

A: Yes, we have strong design team and technical team. Therefore we

can also accept OEM and customized order with special requirements.

For more details, please click "Send" now, we are always willing to

help you.

1. Installation & debugging

After equipments reached the workshop of customer, place the

equipments according to plane layout we offered. We will arrange

seasoned technician for equipments installation, debugging and

testing production at the same time to make the equipments reach

the rated producing capacity of the line.