Zhangjiagang HuaDong Boiler Co., Ltd. |

|

Verified Suppliers

|

|

Biomass Steam Boiler Carbon Steel Boiler Economizer H Fin Tube

Quick Details Specifications

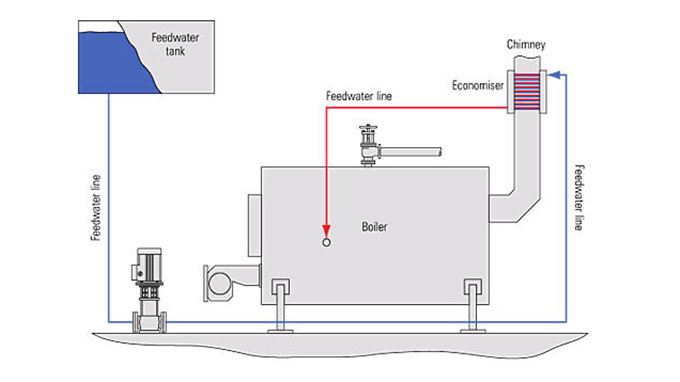

As a kind of environmental protection equipment, economizer is the essence of a heat exchanger, both through two existed in the equipment for heat transfer temperature difference of the medium, to the secondary utilization of equipment, due to the burning boiler industry more for gas, use of the heat exchanger is commonly gas gas heat exchanger, air heat exchanger, water is usually installed in the tail gas boiler flue gas recycling waste heat of smoke directly.

Flue gas economizer has many advantages, the effect on the flue gas heat, transfer to the low temperature medium, so as to reduce the exhaust temperature, reduce the loss of hot smoke, some manufacturers reuse high temperature waste heat flue gas and air heat exchanger, recovery of air we can be used as an air preheater, used to reduce the consumption of coal fuel.

Competitive Advantage

1.Fuel saving: After the high temperature fuel gas released by fuel combustion transfers to the boiler water wall tubing, superheater, and reheater, the temperature is extremely high, the economizer makes it ideal for preventing heat loss. The economizer located at the flue of the boiler reduces the flue gas temperature, and maximizes the heat recovery to lower customer fuel costs.

2.Improvement of boiler steam drum working conditions: When entering the steam drum, the temperature of the feed water is increased after it has been heated using the economizer. The thermal stress caused by the temperature difference between the steam drum wall and the feed water is reduced, thus reducing the shrink and swell of the steam drum, and extends the service life.

3.Cost reduction of coal fired boilers: Water is being heated in the boiler economizer made using low temperature material. This makes the economizer a less costly replacement for high temperature boiler water wall tubing, and reduces overall boiler manufacturing costs.

Economizers must be sized for the volume of flue gas, its temperature, the maximum pressure drop allowed through the stack, what kind of fuel is used in the boiler, and how much energy needs to be recovered. Economizers designed for natural gas only, would likely plug-up if installed on a coal boiler and would face increased risk of corrosion if installed on an oil-fired boiler. Some units are designed to keep the flue gases above condensation temperature, and others are made of materials that resist the corrosive effect of condensed flue gases.

Parameters

| Description | Boiler economizer |

| Material | Alloy steel, Carbon steel, SA210C ,SA213T22, etc. |

| Material standard | ASTM, EN or ISO etc. |

| Dimension | Customization |

| Weight | Min: 10 ton Max.:1000 ton |

| Smelting Process: | EF+LF + VD |

| Process | Material→Ingot → Hot/Cold-Rolling→ Heat treatment (Normalizing+ tempering) → Inspection →rough machining→UT →2nd Heat treatment →finishing machining →Inspection |

| UT standard | ASTM A388 or EN10228, etc |

*Note:HD BOILER can bespoke special type of economizer according to customer's requirement.

Internal heat exchangers

1.Subcooling may also be produced by superheating the gas leaving the evaporator and heading to the gas compressor.

2.These systems withdraw heat from the liquid line but heat up the gas compressors suction.

3.This is a very common solution to insure that gas reaches the compressor and liquid reaches the valve.

4.It also allows maximum heat exchanger use as minimizes the portion of the heat exchangers used to change the temperature of the fluid,and maximizeds the volume in which the refrigerant changes its phase.