WENZHOU HUALE MACHINERY CO.,LTD |

|

Verified Suppliers

|

|

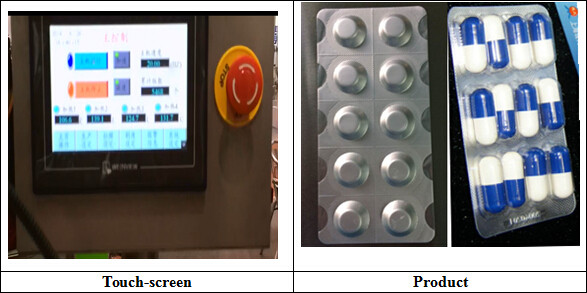

Pharmaceutical Small Alu Alu Blister Packing Machine GMP Standard

Small Alu/Alu Blister Packing Machine is specially designed for hospital dosage room, laboratory institute, health care product, middle-small pharmacy factory, and featured by compact machine body, easy operation, stroke adjustable, long durability etc, It can protect the material from steam or dust, improve product packing degree, and increase the additional value. The machine is used to produce small quality and many kinds of products by changing mould.

Specifications

Model | ALU ALU | ALU-PVC | |

Machine Body | Stainless Steel 304/316 | ||

Blanking frequency(times/min) | 15-30 | 20-45 | |

Adjustable pulling length | 30-120mm | ||

Blister Plate Size | Design According To Customers’ Requirements | ||

Max Forming area and depth(mm) | 140*110*12 | 140*110*15 | |

Air compressor(self-prepared) | 0.6-0.8Mpa ≥0.4m3/min | ||

Mould cooling | (Recycle water or circulating water consumption) 40-80 L/h | ||

Power supply(Three phase) | 380V/220V 50HZ 3KW

| 380V/220V 50HZ 5.5KW

| |

Wrapper specification (mm) | Alu Alu Foil 150*(0.14-0.18)*(Φ400) | PVC 150*(0.15-0.4)*(Φ400) | |

Aluminum Foil:150*(0.02-0.15)*(Φ400) | |||

Overall Dimension(L*W*H) (including foundation) | 2400*650*1450 | ||

Dimension of Each Part | 1350*650*1250(front) | ||

1050*650*1450(back) | |||

Weight | About 800kg | ||

Applications

This product adopts international popular materials with good sealing,anti-moisture, protecting from light, using a special cold forming. It is a new equipment in the pharmaceutical industry, which will combine both functions, Alu-Alu and Alu-PVC by changing moulds.

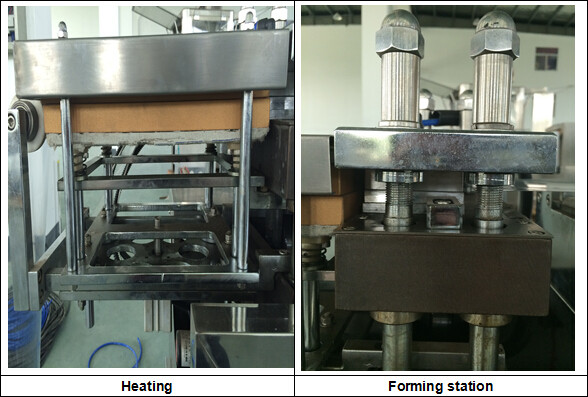

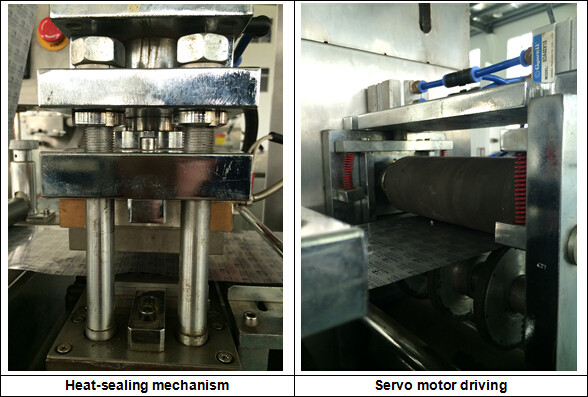

Description

Competitive Advantage

1.All of the air supply and synchronization of the machine is controlled by the encoder. All synchronous data

have been programmed in advance so that there is no need to adjust air supply and pulling time manually. The

machine in other factory use Cam control, which means the process is mechanical. The biggest disadvantage

of it is that the friction is inevitably which will lead to wear and tear. As time passes, the synchronization is not

accurate. But our machines use encoder control, so that there is no need to worry about the synchronization.

If the encoder is broken, you can also buy it in the local, it’s convenient.

2. Our machine use Stepper motor to control the pulling length. When change the model, there is no need to

adjust the machine so that it’s convenient and easy operating. What I want to mention is that the machines in

other factory use gas clip to control the pulling length. It has two shortcomings. First, when you change the

models, you need to adjust the pulling length manually which means adjusting screw in the pulling position. If

the Operating workers is unskilled, it will waste the material and time.

3. Our machines have PRC (print register control) system, is the cursor version of function, because the

machine is a stepper motor, so is true of PRC system forever won't generation shift. Other manufacturers may

be gas clip can only be manually adjusted, a long time after the shift will occur.

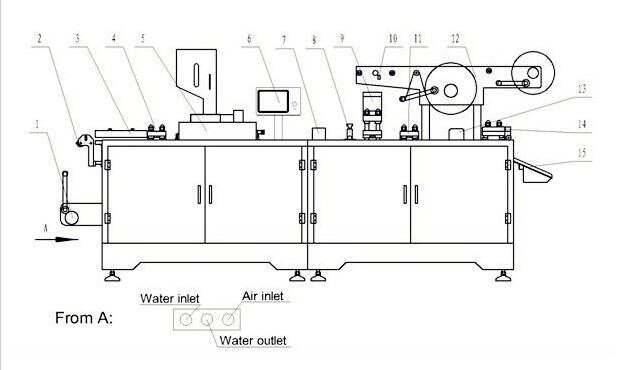

Machine sketch

Attention

When make ALU ALU product:

Turn off No.3 (Heating box),change the feeder to shaking type feeder and change molds(Forming up and

down molds, sealing up and down molds, blanking up and down molds)

When make ALU PVC product: Turn on all of the stations.