Jiaxing Jingkai Qixing Machinery Manufacturing Factory |

|

Verified Suppliers

|

|

Plant Fibre Biodegradable Tableware Machine

Environmental Friendly Plant Fibre Product Making Machine Biodegradable Tableware Machine Disposable Food Packaging Container Machine

Our entire range of machines includes four machines:

1. Sheet Extruder

2. Blister Machine

3. Punching and Cutting Machine

4. Crusher Crushing Machine (for recycling scrap edge into raw material granules)

We are among the leading manufacturers, suppliers and exporters of a wide range of Sheet extrusion and blister forming Integrated all in one machine that is highly appreciated for being reliable and compact. This fully automatic production line is for producing food boxes, trays, bowls, plates and so on. / This fully automatic production line produces food boxes, trays, bowls, plates, etc.

Easy lift angle

Easy to open and close, easy to use

Stronger sealing

Buckle cover tightly

Good sealing, not easy to leak

Better freshness

Reinforced chassis

Plus fixed type, strong pressure resistance

Not easily deformed

Automatic Sheet Extrusion and blister forming All in one Integrated machine Production Line

Schematic Diagram of the Process Flow of Sheet Extrusion and Blister Forming All in One Machine

Mechanical structure diagram

Sheet Extruder

First, prepare the raw material granules needed to make the product.

Granules are then melted and thoroughly mixed in the extruder part of the machine. Then, it comes out of the extruder outlet valve in the form of a paste-like sheet due to high pressure and high temperature. The dough taken out from the colander part of the machine is pressed between the colander rollers and adjusted to the specified thickness. The obtained roll is hardened and the width of the sheet is determined based on the relevant tableware required sheet. The produced roll enters the “roll collector” part of the machine. Finally, the output sheet of the conveyor part is collected as a roll on special rods.

Blister Machine

Blister machine is also called thermoforming machine, Vacuum forming machine. It is a machine that sucks thermoplastic plastic or Bio-based degradable environmentally friendly materials rolls such as PP, PS, PE, EVOH, PBAT, PLA, etc., into various shapes of food containers packaging boxes, bowls, plates, trays and other products.

Product Track

Conveyor rails on the blister machine, including racks, chains, gears, support rods, limit rods, auxiliary rods, motors, etc.

Punching and Cutting Machine

The punching machine is a kind of mechanical equipment that, after the raw materials are installed, driven by the power mechanism, the punching die acts on the material to complete the punching. The punching machine can perform operations such as sheet processing, stamping, molding, embossing, etc. to force the metal into the mold.

The cutting machine is used for the division and cutting of sheets in all walks of life, it does not need any mold; it is controlled by the system software, and then directly cuts the product, as long as the corresponding parameters are set on the operating platform, the computer The corresponding instructions are transmitted to the cutting machine; the cutting machine will quickly cut according to the accepted design drawings, with high automation procedures and simple operation. It is also the cutting equipment used in our Integrated all-in-one sheet extrusion and blister forming machines.

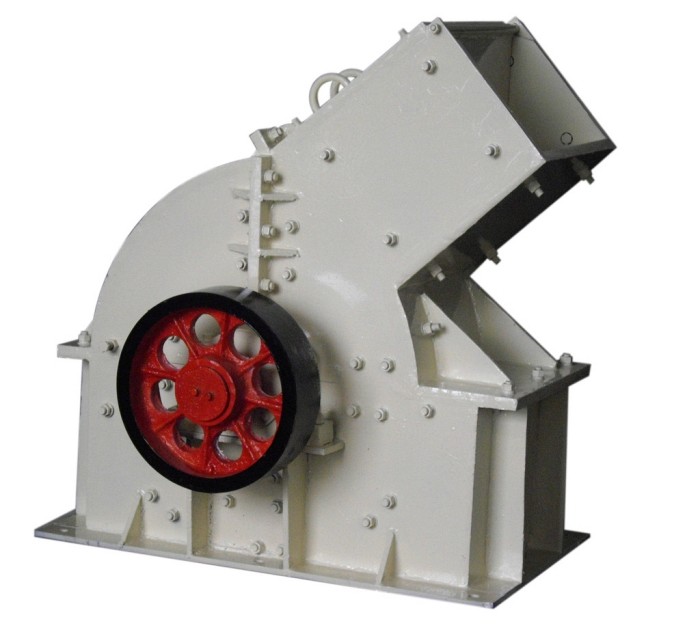

Crusher Crushing Machine (for recycling scrap edge into raw material granules)

The extra sheets obtained from the Blister thermoforming machines enter the crushing recycling machine also called the smash recycle machine grinder or grinding machine at the end of the biodegradable tableware production line. All the remaining sheets are grind and later enter the mixing room. After mixing and pulverizing, the grinded sheets are mixed with corn starch and other additives and again enter the granule making machine, which is the start of a biodegradable tableware production line. As it is clear from this description, the waste of producing biodegradable tableware is zero. Therefore, all raw materials are used in the line by different types of biodegradable machinery.

| Product Advantages | |

| Cut costs | Sheet extrusion and blister forming all in one integrated machine, that can produce products directly from raw material pellets (including leftover materials, fillers, etc.), with one step in place to complete the extrusion sheet and plastic molding all the processing processes, which may be the equipment with the least investment, the lowest production cost and the highest production efficiency. |

| Increase productivity | Our fully automatic production line Integrates extrusion, forming, cutting, stacking and counting, which can bring you more productivity. |

| Low Machinery Investment | Each line comes with all associated equipment that clients need to produce products: sheet extruding machine, forming machine, automatic punching machine and cutting machine, one set of customized mold and punching knife. |

| Low Energy Consumption | The sheet extruding machine produces sheets directly for product forming and punching. one-time heating only, No secondary heating requires, saves power. |

| Adapt Multi-Material | PP, PS, PE, EVOH, PLA, PBAT, plant straw, rice husk, rice bran, bamboo powder, starch and other compostable plant fiber. |

| Multi-Application | By changing mold, the machine line is able to produce takeaway boxes, fast food boxes, burger boxes, cake box, bread box, sandwich box, various food containers, clamshell boxes, takeout boxes, fruit and vegetable packaging boxes, supermarket food tray, bowl, plates, etc. All molds can be customized according to the client's needs. |

| Wide range of applications | This machine is particularly advantageous for food lunch box products, and can also be widely used in the production of food, electronics, toys, hardware and other packaging products, as well as the inner tray of industrial packaging products. |

| Durable and Reliable | The machine line is able to be running 24 hours without problem, Only Requires basic maintenance. |

| No material wastage | Side material can be smashed and re-mixed to be used again. There is no material wastage, no gas pollution, and no water pollution during the production process. |

| High Automation and Easy Operation | Two workers are able to operate the full line each shift. One worker for packing and one for side material re-usage, saves labor costs. |

| Save money | The machine reduces investment by about 50%, saving 30% of electricity, improving efficiency by 30%, reducing labor intensity, and enhancing economic benefits. |

Scope Of Application

Our machines are suitable for the following materials :

1. Thermoplastics: PP, PS, PE, EVOH, etc.

2. Thermoplastic biodegradable plastics: PBAT and PLA, etc.

3. Bio-based degradable environmentally friendly materials, fully biodegradable plant fiber materials: grain fiber, corn starch, plant straw, rice husk, rice bran, bamboo powder, wood powder, bagasse, etc.

4. Bio-based composite materials, biodegradable plant fiber blend materials: talcum powder, calcium carbonate, etc.

5. Multilayered materials, Mineral-filled materials.

Our machines are not suitable for the following materials : PET, PVC, ABS

Three / triple Screw One Step Extrusion Blister Forming Integrated Machine Configuration

| Accessories | Quantity | Note |

| ф90/90/65/ three / triple screw extruder | one | Four-layer co-extrusion ABCA |

| 1250 high speed chain forming machine | one | Form in 0.2 seconds |

| 1250 pneumatic forward/recoil punch | one | Sent pieces with the servo. Can be replaced by a servo punch or automatic counting automatic stacking low noise electric punch. |

| Cast aluminum mold | one | You can change that for CNC carved aluminum mold |

| Press cutter | one | Hardware mold |

| The Main Parameters of QH-90/90/65 | |||

| Max output per hour | 315-375kg | Electric consumption per hour | 55-60KW |

| Maximum molding area | 850MM*300MM | Production speed | 45-60 mode/min |

| Maximum molding depth | 80MM-120MM | Operator needed | 2 |

| Vacuum forming speed | 0.2 seconds | Dimension of the product | Length:12.5-15M, Width:2M |

| Product thickness range | 0.2MM-0.9MM | Whole weight of the product | 6.8 ton |

| The Main Parameters of QX90/90/65 Three Screw Automatic Production Line | ||||

| Machine type | accessories | type | brand | note |

| Extruder | Mold | 1200MM | Ogilvy | |

| Layered device | page-swinging ABCA | Ogilvy | ||

| 90 Net changer *2 | Type 120 | Ogilvy | Hydraulic net changing | |

| 65 Net changer | Type 100 | Ogilvy | Hydraulic net changing | |

| 90 Gear box | Type 200 | Fen jin | ||

| 65 Gear box | Type 173 | Fen jin | ||

| The 90 screw *2 | 90*3000 | Jing Zheng | ||

| The 65 screw | 65*2100 | Jing Zheng | ||

| The 90 motor *2 | 30KW | Zhe jiang Great speed | ||

| The 65 motor | 11KW | Zhe jiang Great speed | ||

| The 90 inverter *2 | 30KW | Wei Chuang | ||

| The 65 inverter | 11KW | Wei Chuang | ||

| Temperature controlled circuit breaker | Solid state relay | Meg 90A | ||

| contactor | Zheng Tai | |||

| Heating coil | Infrared ray | |||

| Hydraulic station | Three way manual valve | |||

| Molding machine | high speed forming machine | 850MM | Form in 0.2 seconds | vacuum pump included |

| Automatic punching machine | pneumatic forward/recoil punch | 850MM | sent pieces with the servo | |

| Mould | One set | Along with the sample | ||

| Toolkit | One set | |||

| Wearing parts | One set | |||

Auxiliary Equipment (Optional, Available for Purchase on Behalf Of)

| High Collocation Fully Automatic Feeding Machine | |||

| Machine type | quantity | Note | |

| 700CM Pulverizer | 1 | You can buy it yourself from the local factory, if you don’t need fully automatic material feeding machines, three mixing pots and one pulverizer machine are enough, if you have these machines in your factory you can spare the money. | |

| One ton stand mixer | 1 | ||

| 0.5 ton stand mixer | 1 | ||

| 3.5M fully automatic material feeding machine | 2 | ||

| mixing pot | 1 | ||

WHY CHOOSE US

1. Professional Team

Professional service can recommend suitable products for you.

Factory direct sales can provide optional parameter customization.

2. Quality assurance

Our company has its own research&development and production base, the products have been seriously inspection the process department to control the quality before they leave the factory, ensure you receive a good quality machine.

3. Quick shipment

Whether you have your own freight forwarder or want us to organize the shipment, our purchasing department and the logistics department can do their best for you. We will provide the best transportation arrangement, according to your plan, to maximize your efficiency.

4. Shopping Guarantee

We have a professional service team, we can give you useful advice and the best packing solution. We 24 hours online service, and strive for an immediate response, to provide you with a wonderful procurement experience.