Skywin Foodstuff Machinery Co., Ltd. |

Factory Price Soft Biscuit And Cookie Production Line

Machine component:

1. Chinese famous brand motor & gearbox

2. Main bearing use Chinese brand, other small use NSK

3. AirTAC Pneumatic cylinder for belt tension and deflecting adjustment

4. PU and Cotton belt

5. 304 Stainless steel cover, thickness 1.5mm

6. SIEMENS transducer electric and PLC touch screen control.

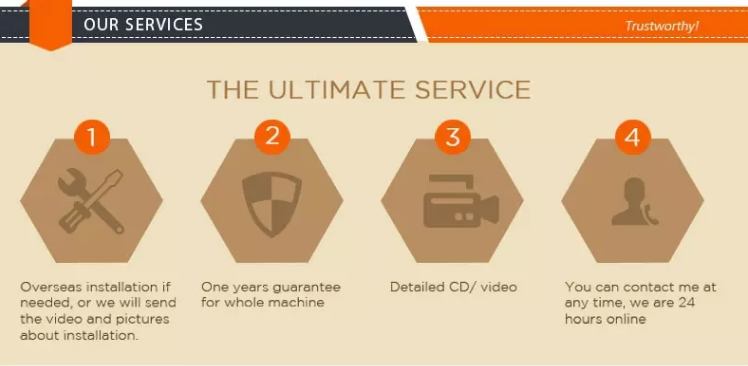

7. Guarantee for 1 year along with recommended spare parts for 1 year.

A whole line consist of:

1. Horizontal dough mixer

2. Automatic dough tipper and feeding system

3. Rotary Moulder for soft biscuit forming

4. Wire-cut cookies machine

5. Salt and Sugar Sprinkle

6. Tunnel oven: Diesel, electric, indirect gas fried or hybrid gas oven for option

7. Oil spraying machine

8. Turning machine 180° or 90° design as per the plant length

9. Cooling conveyor and stacking machine (start wheel stacker or

penny stacker)

Horizontal Dough Mixer

1. Capacity: 150-750kg

2. Multi mixing speed: low speed 25rpm/min and high speed to 50rpm/min

3. Mixing blade is 304 Stainless steel

4. Bowl covered by 304 Stainless steel

5. Machine Cover made by 304 Stainless steel

6. Tipping by Hydraulic pressure

Automatic dough tipper and feeding system

Function: Hydraulic pressure tilting dough, Cut dough into small pieces and send them to the feeding machine(rotary moulder). Tilting time 20-25 seconds around

Rotary Moulder

1. Cotton Belt

2. In-feed from the rotary moulder onto wire mesh belt

3. Adjusted by Handwheels

4. Speed control by frequency inverter

5. Perfect sizing of biscuit with a guarantee of almost equal weight of all biscuits coming out of the machine.

6. Guarantee for 1 year along with recommended spare parts for 1 year.

Cookies machine

Enter Stove Machine

1. Oven Belt Driven System

2. With Belt tracking device

3. Roll diameter: 900mm

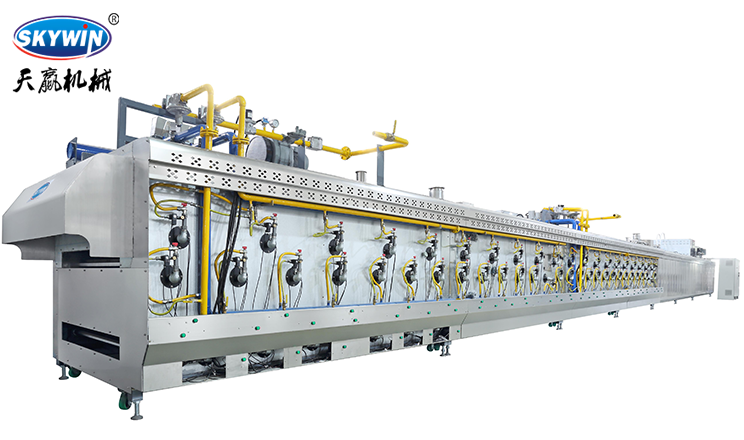

Tunnel Oven

1. The length of Oven body is customized

2. Weishaupt brand Gas burner

3. 3 set pneumatic tracking installed on enter oven, exit oven and oven bottom

4. Pneumatic automatic tracking and adjust belt and tension and Panasonic Sensors .

5. Oven cover by 304 Stainless steel, 1.5mm thickness

6. With endless hand-wheel at the out-let of oven in case electricity power off, can be move out the biscuit in the oven chamber, to protect oven.

7. The oven is suitable for Cracker biscuits, common kind biscuits, each burners can be individual control and general control. PLC memory system for easier operation.

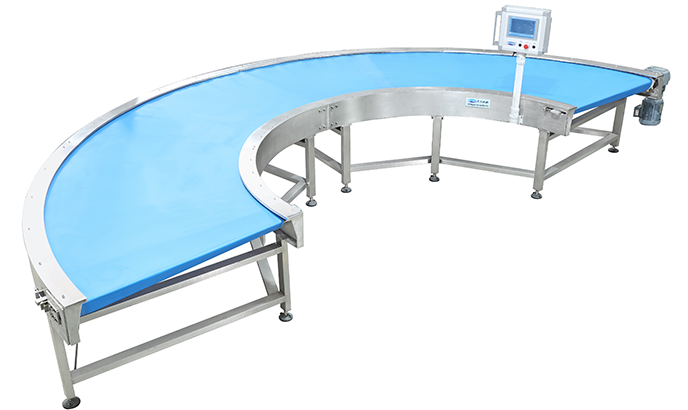

Out stove & Peeling Machine: 180°Curve Machine

1. As transition device from oven

2. Stainless steel mesh belt

Oil sprayer

1. Disc type oil spray machine

2. Disc number 14pcs, top 8 + bottom 6

3. Independent frequency inverter control and adjust

4. Stainless steel mesh belt

5. Multi-layer oil filtering , Oil filter 5m

6. Full 304 stainless steel frame

7. Oil tank was heated by hot water, improving situation of oil go bad.

Cooling conveyor

1. total length according to layout

2. Food grade PU belt width 650mm

3. Independent frequency inverter control

4. 304 stainless steel frame

Stacker

1. Star wheels and penny stacking

2. Food grade PU belt

3. Independent frequency inverter control and adjust

4. 304 stainless steel frame

Packing table

1. PU belt total length according to layout

2. Independent frequency inverter control and adjust

3. 304 stainless steel frame

Tray Type PLC Cookie Machine Hard and Soft Biscuit Production Line Sandwich Connect Packing Machine

Wafer Production Line Horizontal Dough Mixer Rotary Moulder for Soft Biscuit Making

| Step | Process |

| Step 1 | Mechanical surface coated with preservative solution (to protect stainless steel). |

| Step 2 | The plastic cushion packing machine (prevent bump). |

| Step 3 | Plastic film packaging (to prevent ventilation). |

| Step 4 | Wooden case / frame packaging (easy to transport). |

| Step 5 | Tie the bandage outside of the wooden case (reinforcement overall). |

♥ Looking forward to your inquiry♥