Stainless Steel Wire Horizontal Vibrating Screen Durable With Dust

Cover

1. Applications

1. Metallurgy industry

In metal processing industry, this linear vibrating screen can sift

alluminium powder, lead powder, copper powder, alloy metal powder,

electrode powder, manganese dioxide powder, electrolytic copper

powder, abrasive powder, High temperature resistant material,

kaolin, limestone, dolomite, alumina, calcium carbonate, quartz

sand and so on.

2. Pollution abatement

Our linear vibrating screen is also suitable for treating waste

oil, age, accessory ingredient, activated carbon.

2. Brief Introduction

Our linear vibrating screen is a kind of small and medium size

multi-layer screening machinery. Its performance has reached the

international advanced level. Any dry material with a diameter of

0.074mm-20 mm could be handled. The maximum granule diameter should

be less than 30 mm. As a multi-layer screen, this machine could

come with seven layers of screen at most.

3. Characteristics

Feature

1. The screening precision is great, while the blocking rate of

screen is less than 10% in average.

2. The screen frame is usually made of wood, or steel or stainless

steel. If the mesh diameter is large than 2 mm, and the production

capacity is high, the stainless steel frame will be better.

3. Enclosed structure is adopted for the linear vibrating screen to

avoid particulate matter pollution to the air.

4. The low energy consumption and low noise(73-80 dB) make the

machine quite eco-friendly.

5. The screen is woven by stainless steel wire, so its service life

is quite long and the maintenance is simple. It can be used in

single layer for multi-layer(7 layers at most).

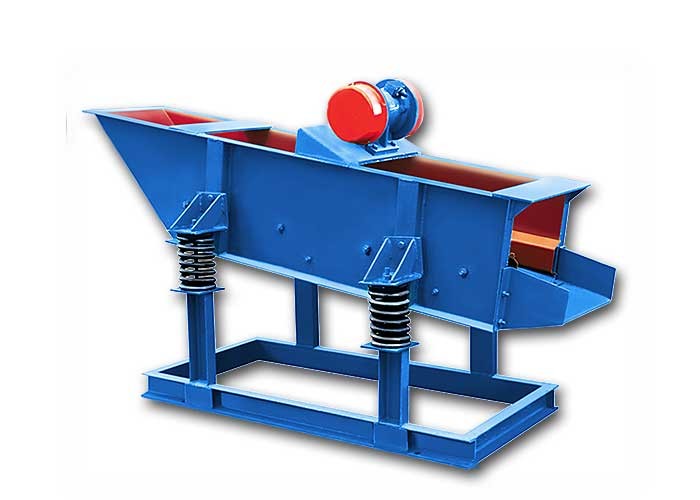

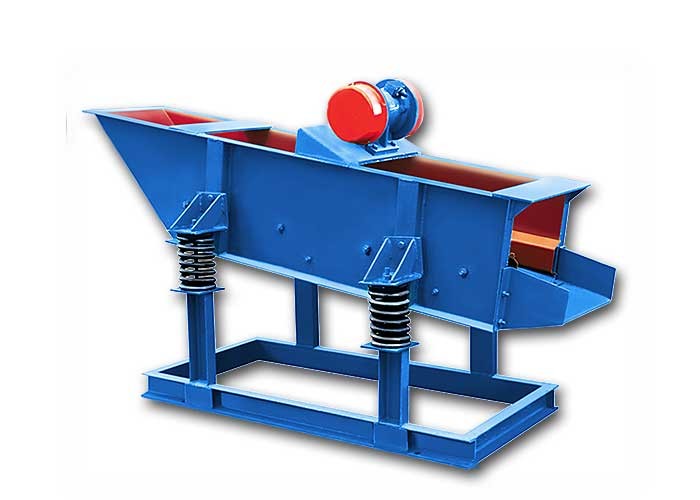

6. The motor could be mounted eighter at the bottom or on the side

of the vibrating body.

4.Matters needing attention

1. Once the machine on operation, the vibration part shall not be

connected or contact with any object.

2. When feeding materials, pay attention to ensure the uniform

feeding.

3. When the material through down, keeping no big impact to damage

the screen.

4. Before operation and power off, there should no be any material

on screen surface.

5. If there is any abnormal sound in the operation, the machine

should be shutdown immediately and to check.

6. Ensure vibration motor maintenance regularly.

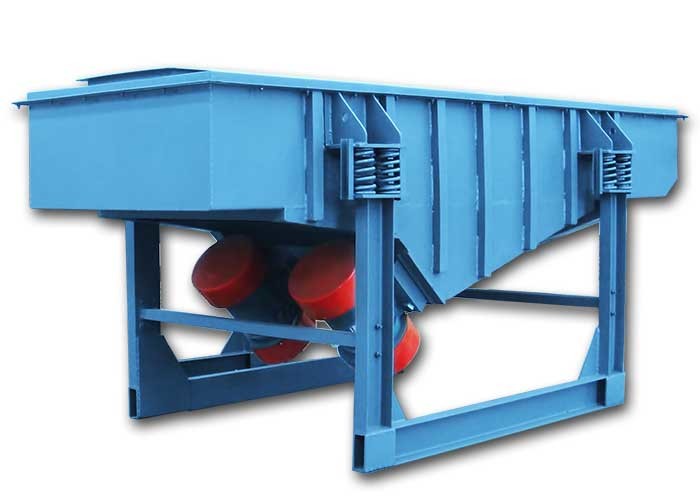

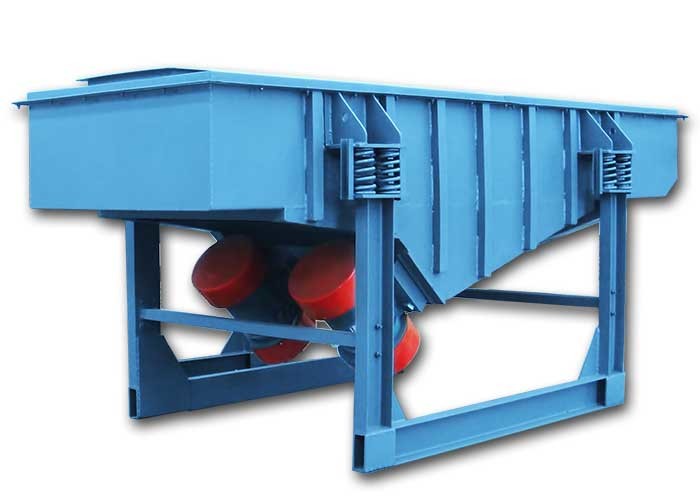

5. Driving Device Classification

-Dual Vibration motor driving

-Vibration exciter driving(for large model screen)

Tech Data

| Model | Screen Surface Size | Screen Cloth Aperture | Capacity | Vibration Frequency | Power | Screen Surface Inclination |

| (mm) | (mesh) | (t/h) | (r/min) | (kw) | (degree) |

| ZS-520 | 500*2000 | 2-325 mesh | ≤ 5 | 1460/960 | 0.4*2 | 0-10° |

| ZS-525 | 500*2500 | ≤ 8 | 0.55*2 |

| ZS-1020 | 1000*2000 | ≤ 12 | 1.1*2 |

| ZS-1025 | 1000*2500 | ≤ 16 | 1.1*2 |

| ZS-1030 | 1000*3000 | ≤ 20 | 1.5*2 |

| ZS-1224 | 1200*2400 | ≤ 23 | 1.5*2 |

| ZS-1525 | 1500*2500 | ≤ 28 | 2.2*2 |

| ZS-1530 | 1500*3000 | ≤ 32 | 2.2*2 |

How to get one set of linear vibrating screen separator? Only by

telling us the following information for selection:

1. Material’s name, bulk density, and water content

2. Capacity you required___kg/h

3. What’s the purpose for our machine? Filtering, removing

impurities or classification?

4. How many layers do you need?

5. The mesh size for each layer

6. Voltage and frequency

Service:

1. Special design offered.

2. Buyer label paste offered.

3. Sample testing support.

4. View our Factory

5. One year warranty.

6. Three years extended warranty.

7. 24 hours inquiry and consulting support.

8. Training how to instal and use the machine