Allwin Machine & Equipment Co.,Ltd |

|

Verified Suppliers

|

|

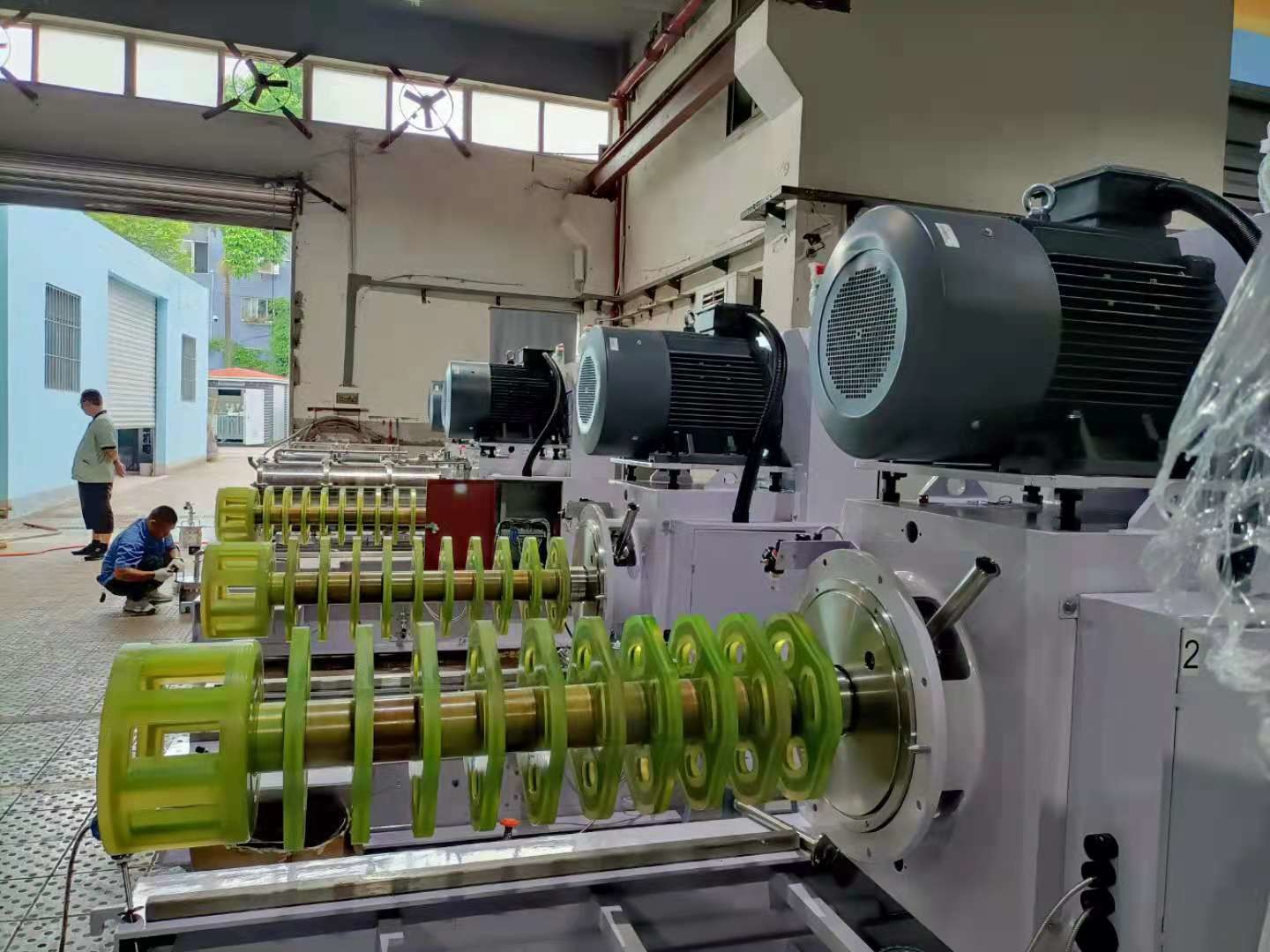

Mass Production 100/250L Disk Type Bead Mill Machine Applicated In Nylon And Chemical Fiber Of TiO2

250/100 liter large flow bead mills are usually used in nylon

and chemical fiber of TiO2 industry. Our machines can help

users save electric fees more than 30%, and also reduce the labor

cost, Meanwhile, the effeciency is at least 20% higher than normal

bead mills. we have many successful experience of grinding chemical

fiber and nylon.Welcome to consult to know more information.

1. Technical data of large flow horizontal bead mill

| No | Main Parameters | SP100 /250 bead mill | Notes |

| 1 | Motor power (kW) | 55/75KW | Ex-proof/non ex-proof available |

| 2 | Effective volume of grinding chamber (L) | 100/250L | volume can be suggested according to different grinding materials and usages |

| 3 | Water pressure (MPa) | 0.3 | |

| 4 | Cooling water consumption (L/min) | 2.0 -3.0 m3/h | Advision: Users offer the Cooling water less 10°C |

| 5 | Dimensions:L*W*H (mm) | --- | |

| 6 | Weight (kg) | About 2300/3200 | Different as for different chamber volume |

| No | Main parts

| SP100/250 | Notes |

| 1 | Material of External vessel | SUS 304 stainless steel | |

| 2 | Material of Inner grinding vessel | SUS 304 stainless steel | different mateials for choice |

| 3 | Material of Dispersing shaft | 40Cr with hard chromium plating | |

| 4 | Material of dispersing system | 304 stainless steel, steel coated with PU | Choose what you need |

| 5 | Feeding and discharging end covers on the cylinder | SUS 304 stainless steel | |

| 6 | Static discharge screen ring | Wire Wound screen ring with 304.Gaps: 0.50.3mm. | dynamic scraper: alloy steel |

| 7 | Mechanical seal | Double end mechanical seal | |

| 8 | Feeding pump | 1.5"/2" ARO diaphragm pump | IngersoII Rand |