KingPo Technology Development Limited |

|

Verified Suppliers

|

|

Temperature and Humidity Walk-in Test Chamber / Walk in Cooling Room

Description

Temperature and Humidity Walk-in Test Chamber suitable for the whole machine or large parts of low temperature, high temperature, high and low temperature change, constant time heat, high and low temperature alternating moisture and heat test...

The size and function of the studio can be changed according to user requirements. Pieced box body, beautiful and generous shape; Scientific airway design can meet the needs of different customers. Using touch screen, PLC program controller.

SPECIFICATIONS

| SR NO | SPECIFICATION | KP-WI1500 |

| 1 | TEMPERATURE RANGE | -50C TO +100C |

| 2 | HUMIDITY RANGE | 40% TO 98% RH |

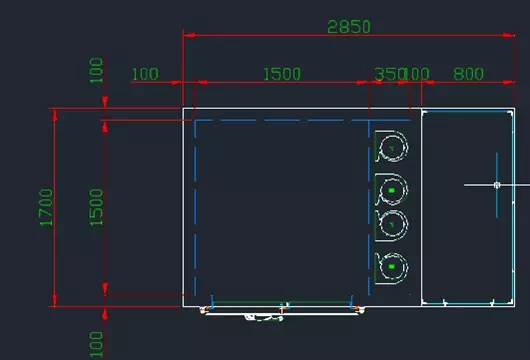

| 3 | DIMENSION (INTERNAL) (W X D X H) | 1500 X 1500 X 3000 MM |

| 4 | DIMENSION (EXTERNAL) (W X D X H) | 2850 X 1700 X 3200 MM |

| 5 | RAMP | VARIABLE, TEMP. 0~5C / MIN & HUMIDITY 0~5%/MIN IN AVERAGE, NO LOAD |

| 6 | ACCURACY | TEMP. ±1C, HUMIDITY ±2.5%RH |

| 7 | INTERIOR WALLS | STAINLESS STEEL 304 |

| 8 | EXTERIOR WALLS | COLD ROLLED STELL PLATE WITH BAKING FINISH |

| 9 | TEMPERATURE & HUMIDITY MEASUREMENT AND CONTROLLER | 32 BIT CONTROL AND MONITORING SYSTEM. INTERFACE FACILITY WITH RS232 PROGRAMMABLE TEMP. HUMID. CONTROLLER |

| 10 | VIEWING WINDOW | MULTI PANE GLASS WINDOW SIZE |

| 11 | PORT HOLES | 50 MM DIAMETER FOR WIRE ROUTING |

| 12 | POWER SUPPLY REQUIREMENT | THREE PHASE, AC380 V ± 10 %, 50 HZ |

| 13 | SOUND PRESSURE LEVEL | <72DB (A) |

| 14 | CONDENSER COOLING | WATER COOLED |

| GENERAL TECHNICAL SPECIFICATION | ||

| 15 | THERMAL CYCLIC CHAMBER | |

| 15.1 | CHAMBER WITH INTERNAL AIR CIRCULATION, AND ALL THE HEATERS AND COOLING COIL LOCATED BEHIND/BELOW THE FALSE SHEET OF THE CHAMBER AND OUTSIDE THE WORKING SPACE | |

| 16 | INTERIOR | |

| 16.1 | THE CONDITIONING WITH AIR CIRCULATION TO MAINTAIN UNIFORM TEMPERATUR | |

| 16.2 | INTERIOR HAVE PROVISION FOR ARRANGING STAINLESS STEEL | |

| 17 | INSULATION | |

| 17.1 | INSULATION IS ASBESTOS-FREE CSC-FREE, WITH LOW THERMAL CONDUCTIVITY, POLYRTHENE PU FOAM | |

| 18 | COOLING SYSTEM | |

| 18.1 | CASCADE TYPE, REFRIGERATION SYSTEM WITH HERMETICALLY SEALED REFRIGERATION CYCLES WITH ENVIRONMENT AND OZONE FRIENDLY AND CHLORIDE FREE REFRIGERATION | |

| 19 | DOOR | |

| 19.1 | LOCKABLE FRONT OPENING, WITH DOUBLE DOOR LATCH EASY TO OPEN | |

| 19.2 | WITH SILICON GASKET FOR PERFECT SEALING | |

| 20 | VIEWING WINDOW | |

| 20.1 | VIEWING INTERLOCK IS SEALED TO AVOID LEAKAGE AND PROVIDED WITH HEATING PROVISION TO PREVENT CONDENSATION | |

| 21 | ILLUMINATION | |

| 21.1 | INERNALLIGHT ON VIEWING WINDOWS WITH EXTERNAL CONTROL | |

| 22 | TEMPERATURE MEASURING AND CONTROL SYSTEM | |

| 22.1 | THE TEMPERATURE MEASURING AND CONTROL SYSTEM ADOPTS MICROPROCESSOR SYSTEM AND PROVIDED WITH TOUCH PANEL FOR MONITORING AND DIGITAL DISPLAY: SUPPLIED WITH SUPPORT SOFTWARE SOFTWARE IS CAPABLE TO VISUALIZE AND GRAPHICAL ANALLYSE THE MEASURED & RECORDED VALUE. | |

| A. | GRAPHICAL REPRESENTATION AND DIGITAL DISPLAY AND CONTROL OF SET AND ACTUAL VALUES | |

| B. | DIGITAL INPUT AND DISPLAY OF TEMPERATURE IN DEGREE CENTIGRADE | |

| C. | FAULT DIAGNOSIS SYSTEM | |

| D. | 120 STROAGE OF PROGRAMMES | |

| 22.2 | HAVE ADJUSTABLE SAFETY CUT-OUT AGAINST HIGH AND LOW TEMPERATURE | |

| 22.3 | FACILITY TO PROGRAMME TEMPERATURE MEASURING USING SENSOR PT100 | |

| 23 | RECORDER & PC CONNECTIVITY | |

| 23.1 | STANDARD RS -232 INTERFACE FOR PC CONNECTIVITY | |

| 23.2 | RS-232 CABLE FOR PC CONNECTIVITY ALONG WITH PC CONNECTIVITY SOFTWARE | |

| 24 | PORT HOLES | |

| 24.1 | EACH PORT HOLE PROVIDED WITH SILICON SEALING BUNKER (PLUG) | |

| 25 | ELECTRICAL PANEL | |

| 25.1 | ALL POWER CONNECTORS, PROTECTION DEVICES POWER CONTROL LOGIC BUILT IN THE CONTROL PANEL INTEGRATED TO THE CHAMBER | |

| 25.2 | ALL ELECTRICAL CABLES TAGGED WITH ID NUMBER | |

| 25.3 | ALL ELECTRICAL FUNCTION CIRCUIT EQUIPPED WITH ITS OWN SAFETY DEVICE THAT SHUTS DOWN THE RELEVANT CIRCUIT OR THE ENTIRE TEST CHAMBER IF A FAULTY DEVELOPS | |

| 25.4 | ALL ELECTRICAL SYSTEMS COMPLY WITH RECOGNIZED TECHNICAL REGULATION AS WELL AS WITH THE ACCIDENT PREVENTION REGULATIONS. | |

| 26 | STANDARD PROTECTION | |

| 26.1 | PROTECTIVE FEATURE TO BE PROVIDED AS FOLLOWS: | |

| A. | OVER LOAD TRIP & EARTH LEAKAGE TRIP FOR COMPLETE CHAMBER | |

| B. | OVER LOAD TRIP FOR COMPRESSORS, HEATERS AND MOTORS | |

| C. | OVER TEMPERATURE CUT-OFF FOR COMPRESSORS | |

| D. | HEATER BE CUT OFF, IF AIR CIRCULATION BLOWERS ARE OFF | |

| 27 | OPERATING SYSTEM | |

| 27.1 | DETAILED OPERATING & MAINTANANCE MANUAL | |

| A. | OPERATIONAL INSTRUCTION | |

| B. | COMPLETE LIST PARTS | |

| C. | PREVENTIVE MAINTENANCE PROCEDURE | |

| D. | TROUBLE SHOOTING MEASURES | |

HUMIDITY RANGE: DETAIL CHAMBER IMAGE:

CHAMBER DRAWING