Shenzhen Chebao Technology Co., Ltd |

|

Verified Suppliers

|

|

High Quality Automatic Battery Spot Welding Machine 135° Rotating Welding Head

● This lithium battery spot welding machine is a multi-axis control machine developed by modern automation experts, which is an automatic production equipment for effective real-time control of processing with precision transmission and motor control mechanism.

● The equipment is suitable for automatic one-sided spot welding of

all kinds of cylindrical cell combinations such as 18650, 21700,

26650, 32700 and so on.

● It is suitable for spot welding of modular lithium battery pack

such as NB/Power Tool/Gardening Tool/High Power/ energy storage

power station battery / electric motorcycle / electric vehicle, and

can be used with lithium battery production line.

● With modular design, low noise, stable energy output, efficient

welding and other characteristics.

● The welding head heightening design can also be used for automatic

welding of protective plates of various pack schemes. It can be used both in one machine and in one machine. When welding

protective plates, you only need to replace the platform fixture.

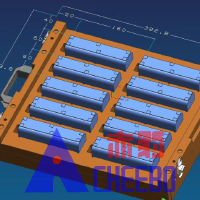

● Double platform design, left and right platforms are welded

independently, do not interfere with each other, or only a single

platform can be used.

● Adopt Taiwan HIWIN guideway, high precision, low noise, smooth

sliding, durable.

● The 135 °rotary welding head design can set the rotation angle of

the welding head according to the slotting position of the nickel

sheet to avoid welding errors caused by the non-rotation of the

welding head.

● It also has the function of anti-sticking needle.

● High-definition LCD touch screen, convenient and simple parameter

adjustment, real-time display the working status of the equipment.

● Independently develop a variety of automatic intelligent systems,

with the intelligent operation of equipment, such as: energy

switching function, production technology function, welding needle

compensation function, manual debugging function.

| Production efficiency | 3000PCS/H | Welding source | Transistor/multipulse (Optional) |

| Welding thickness | 0.02-0.3MM | Type of cooling | Forced water circulation cooling |

| XY shaft welding stroke | 400MM*600MM | Mode of motion | Automatic continuity |

| XY shaft welding accuracy | 0.1MM | Welding pressure | 5KG/F |

| Electrode material | Copper alumina | Machine Dimensions | 1680*1400*2000MM |

| Welding head rotation | Yes | Machine Weight | 330KG |

| Power source specification | Single-phase 220V50/60HZ | Application scenarios | Cylindrical battery welding |

1. Transistor welding power supply

Welding energy output is the most stable power supply, which can display welding voltage and current waveforms in real time, and the current rises quickly, which can realize high-quality welding in a short time.

2. Hd touch screen

Real time display of welding data and welding hole positions. The

system parameter settings are simple and easy to learn.

Support manual programming, CCD mapping, and fast programming by

importing solder joint paths.

3.Cooling system:

Real time display of welding data and welding hole positions. The

system parameter settings are simple and easy to learn.

Support manual programming, CCD mapping, and rapid programming by

importing solder joint paths.

Cell/bracket/battery nickel piece loading fixture -- Place fixture to left platform induction position -- automatic spot welding of the device is

completed to send the fixture to the material retrieval position -- manual flip fixture -- Place the fixture to the right platform induction position --

automatic spot welding of the device is completed to send the material retrieval position -- remove the battery pack from the fixture -- for the next

production cycle (the platform can be put in when the left platform is working) The product, waiting for the platform welding to be completed, will

automatically transfer to the right platform welding. When welding the right platform, the left platform can replace the product, waiting for the right

platform to complete the welding, will automatically transfer to the left platform welding, in turn cycle)

1. Energy storage battery pack 2. Electric bicycle battery pack 3. Battery pack BMS welding

Q: How do I install and run the machine?

A: Our technicians had installed the machine before shipment. For the installation of some widgets, we will send out detailed training videos and user manuals randomly. 95% of customers can teach themselves.

Q :How can I do if the machine goes wrong?

A: If you encounter such problems, please contact us as soon as possible. Do not try to repair the machine by yourself or others. We will respond as soon as possible within 24 hours to solve your problem.

Q: I don't know which one is right for me?

A: Please tell us the following information

1) Battery model and type.

2) Welding material and welding thickness

3) Commercial industry: We have a lot of sales experience and can provide you with advice.

Q:What's your minimum order quantity?

A: We don't have a minimum order quantity. Whether it is an order of 1 or 100, we will wholeheartedly support you.

Q: How does your factory do in terms of quality control?

A: Quality comes first. More than 20 tests will be performed on each unit. After all the tests are passed, our QC will test the welding performance.

Looking forward to your consultation, we will provide you with the best quality service throughout the process!!!