Wuxi Orient Anti-wear Engineering Co.,Ltd. |

|

Bolt Hole For the Inner End Liners Ball Mill Liners High Efficiency

Specification

1. Material:Ni-hard Cast Iron

2. Hardness:≥HRC53

3. Impact Value:AK5-15J

4. Application:Mining Industry

5. MOQ:5tons

High Cr white iron material possess a combination of superior abrasion resistance and a reasonable

degree of toughness. The high Cr castings have longer service life than the other material,such as

high Mn steel and Cr-Mo alloy steel.And now it is widely used in the working condition of high wear and low impact,such as dry grinding process,coal mills,cement mills due to its excellent performance.

Technical Parameters

| Item | High Cr White Iron | High Cr Alloy Steel | High Mn Steel | Ni-hard Cast Iron |

| C | 2.4-3.2 | 1.1-2.2 | 0.9-1.3 | 2.4-3.6 |

| Si | 0.6-1.2 | 0.6-1.2 | ≤0.8 | ≤0.8 |

| Mn | 0.5-1.0 | 0.5-1.0 | 11.0-18.0 | ≤2.0 |

| Cr | 12.0-30.0 | 11.0-30.0 | 1.5-2.5 | 1.5-10 |

| S | ≤0.04 | ≤0.04 | ≤0.04 | ≤0.15 |

| P | ≤0.06 | ≤0.06 | ≤0.06 | ≤0.15 |

| Mo | 0.1-3.0 | 0.1-3.0 | ≤1.0 | ≤0.1 |

| Cu | 0.1-1.0 | 0.1-1.0 | - | - |

| Ni | 0-0.3 | 0-0.3 | - | 3.3-10 |

| Re | - | - | - | - |

| Equivalent Specification | GB/T8263-1999 AS2027 Cr27 AS2027 CrMo 15/3 AS2027 CrMo 20/2/1 ASTM A532 Class Ⅲ Type A 25%Cr ASTM A532 Class Ⅱ Type B 15%Cr-Mo BS 4844 3E DIN1695 NFA32401 | GB/T5680-1998 DL/T 681-1999 JIS G 5153-1999 ASTM A128 DIN GX120Mn12 AFNORZ120Mn12 | GB/T8263-1999 AS2027/Ni-Cr1-550 AS2027/Ni-Cr2-500 AS2027/Ni-Cr4-500 AS2027/Ni-Cr4-600 AS2027/Ni-Cr4-630 ASTM A532 1-A,B,C,D ASTM A532 2-A,B,C,D,E ASTM A532 3-A | |

| Material Type | Martensite Matrix | Austenitic Mn Steel | - | |

| Hardness | HRC≥56 | HB≤300 | HRC≥56 | |

| Impact Value | AK≥4J | AK≥80J | - | |

Production Facilities

1T,1.5T,3T,5T,12T,15T

Induction Electrical Furnace Heat Treatment Electrical Furnace

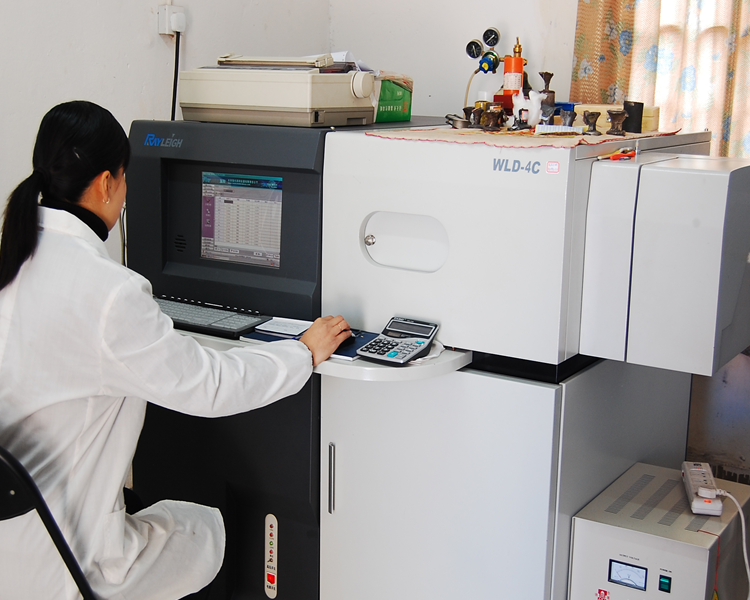

Inspection Facilities

Spectrometer Portable Hardness Tester

UT Test Electronic Metallographic Microscope

Process

Honor

About Us

We are a Chinese specialized manufacturer of wear, heat and corrosion-resistant castings.

Our main products are ball mill liners, grinding media and wear parts for crushers.

The area for our foundry is about 30,000 square meters. The capacity of our company is 30,000MT/year

and the single piece is from 15kg to 20tons. The capacitiesof Mid-frequency induction electric furnaces

are 15tons,12tons, 5tons,2tons,1.5tons and 1.2tons. And we have 10 sets of heat-treatment electrical furnaces with capacity of 30 tons, 10 tons,3 tons.

Our Services

We supply the following services:

1. Production of qualified wear and heat castings;

2. Design and installation of the boltless mill liners;

3. Consulting service of material selection of the mill liners

under specific working condition to achieve

longer service life;

4. Consulting service of production & fineness improvement of

grinding mills.

5.We can provide OEM/ODM for our clients.