ZhongHeng Machine Manufacture Co.,Ltd |

|

15 rows Ridge Cap Roll Forming Machine cold roll forming equipment

1. Suitable to process: Color steel plate

2. Width of the plate: 400mm

3. Rollers: 11 rows

4. Dimensions: 5.4*1.15*1.51m

5. Power: 3+3kw

6. Rolling material: 45# steel(plated chrome on surface)

7. Thickness of the plate:0.3-0.6mm

8. Voltage: 380V 50Hz 3phases

9. Material of the cutting plate: Cr12

10. Hydraulic: 40#

11. Processing precision: Within 1.00mm

12. Control system: PLC control

Description

This machine produce two models of roofing is the most popular

model of roofing,its widely used in roofing and wall of the

workshop.

There is two cylindas on the cutting head of this machine,the

hydraulic oil is running into the cylinda,control the cutter

easily.

Specification

NO. | ITEM | PARAMETER | NOTE | |

1. | Suitable | Type | Pre-painted sheet, |

|

Width(mm) | 500 |

| ||

Thickness(mm) | 0.3-0.8mm |

| ||

Yield stress(mm) | G220-G300 |

| ||

2. | Product | Detail as the attached file | ||

Length | Any length |

| ||

3. | Power | Type | 380v/3ph/50hz | Motor brand shanghai Lichao |

Main Motor power | 5.5kw | |||

Cutter power | 4kw | |||

4. | Forming speed(m/min) | 2m/min | Not include the time of cutting | |

5. | Manual Decoiler | Type | Manual |

|

Max capacity | 5t |

| ||

Suitable coil OD(MM) | 1250 |

| ||

Suitable coil | 508 |

| ||

6. | Forming stand | 15 | Depend on actual design | |

7. | Thickness of structure | 16mm |

| |

8. | Forming shaft diameter(mm) | 70 solid |

| |

9. | Type of cutting | Roll formed and |

| |

10. | Control system | Panasonic PLC and inverter |

| |

11. | Install dimension(depend on the final design) | 8.8m×1.5m×1.3m | Without panel length | |

12. | Total weight (Approx) | 4.5T | Depend on final design | |

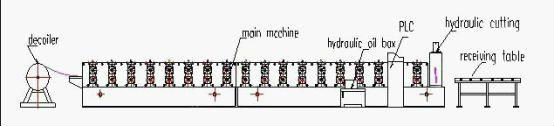

Flow chart

Uncoiling→Feeding material into machine→Roll forming→Measuring length→ Auto cutting

→Products receiving

Applications:

Roof panel / wall panel

are widely used in building: the steel-structured large-scale warehouses, plants, supermarkets,

shopping malls, trade markets, stadiums, holiday villages, sanatoriums, hotels, villas, residences, and

different kinds of greenhouses. What's more, equipment can be designed and manufactured as customers'

requests.This model is hot in Mexico.

Competitive Advantage:

1. save space

2. easy installation

3. perfect service

4. excellent quality

5. Operate easily