shenzhen xingte technology co.,ltd |

|

Verified Suppliers

|

Automatic flyer motor winding machine with 6 work station for rotor

coil winding

This 6-station flyer morot winding machine is 5-6 times more

efficient than the double-flying fork winding equipment currently

on the market. It is fully automatic loading and unloading and

requires only one person to operate. The equipment has a compact

design, a small footprint and reasonable use of space. It consists

of core loading, winding, finishing, testing, blanking and other

processes.

Product Features:

It seems like there was a repetition in the points you provided. Here is a summarized list of the features mentioned:

1. Automatic loading and unloading of the assembly line, with

automatic separation after rotor qualification, ensuring simple

operation.

2. Short cycle time, high efficiency, suitable for mass production.

3. Can be operated by a single machine, integrated into a fully

automatic rotor production line, and compatible with MES systems

4. Capable of drilling in angular (chamfering), radial, and axial

directions to remove weight based on workpiece characteristics.

5. Utilizes brand components for main electrical parts, ensuring

stable and reliable equipment performance.

6. Features a soft-supported high-precision measurement system for

accurate data and good repeatability.

7. Includes photoelectric safety protection, with automatic alarm

and shutdown in case of failure.

The flyer motor winding machine products Features

Flexibility (internal and external rotor)

Multi-parts winding at the same time

Freely programmable

Wire layering

Freely programmable contacting/wire termination (teach process)

High filling factors despite required space for needle

Large wire diameter range

Freely selectable wire connections even on the lower side of the

stator

Low tooling costs

Typical products where flyer motor winding machine is used

Pump drives

Fans

Power steering, servo motors

various brushless motors

Professional food processors

Professional power tools

Coolant pumps

Heating pumps

Vacuum pumps

Oil pumps

Roller shutter drives

Wheelchair drives

Dental drill

Product parameters

Model | XT-F06D |

No. of stations | 6 stations |

Rotor outer dia. | Ref: Max. Ø28mm |

Rotor Stack height | Ref: Max. 40mm |

Applied Wire size | Ref: Max. Ø0.5mm |

Rotor accuracy | 0.1° |

Winding speed: | Ref: Max 6000 rpm(depends on Rotor pec.) |

Power supply | AC 220V,50/60Hz |

Power | 4.5Kw |

Air pressure | Min. 0.6MPa |

Machine dimensions | 1,100(L)x1,560(W)x1,800(H)mm |

Machine weight | Approx. 700kgs |

Information required for proper rotor Winding Machine inquiry.

It would be helpful if the customer could send us a detailed

drawing that includes the following information:

1. Drawing of the rotor lamination.

2. Drawing of the assembled rotor.

3. Drawing of the rotor stack.

4. Drawing of the rotor winding diagram, indicating the rotor wire

diameter and the number of turns.

5. Drawing of the commutator.

6. Required productivity level.

7. Any other technical requirements.

If possible, it would be even better if the customer could send us

samples.

Our company pictures

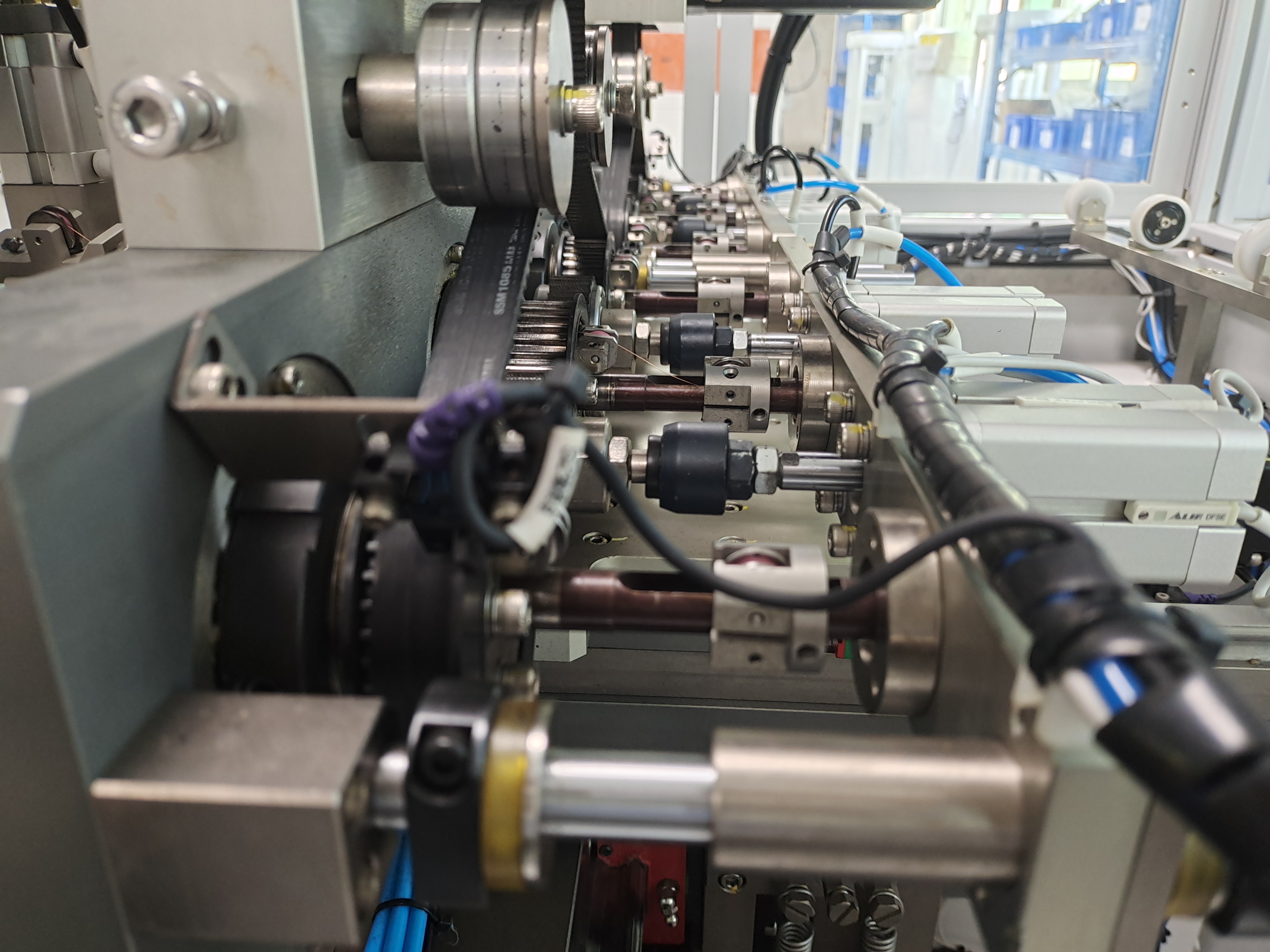

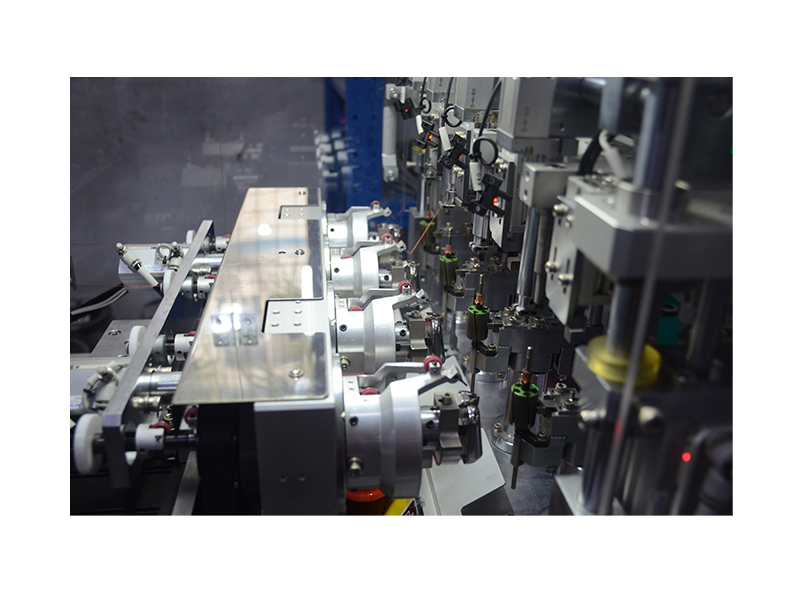

Pictures of machine

Rotor samples

Application

Our machines are mainly applied to induction motors, BLDC motors,

universal motors, three-phase motors, single-phase motors, AC

motors, DC motor, such as washing machine motors, air conditioner

motors, pump motors, cooler motors, alternator motors, fan motor,

ceiling fan motor, compressor motor, power tool motor, vacuum

cleaner motor, mixer motor, series motor, electrical car motor,

wheel hub motor, electric toothbrush motor, hair dryer motor,

electric shaver motor, etc.