zhangjiagang aquatrin Machinery co.,ltd |

|

Filling Part

Cap loading machine

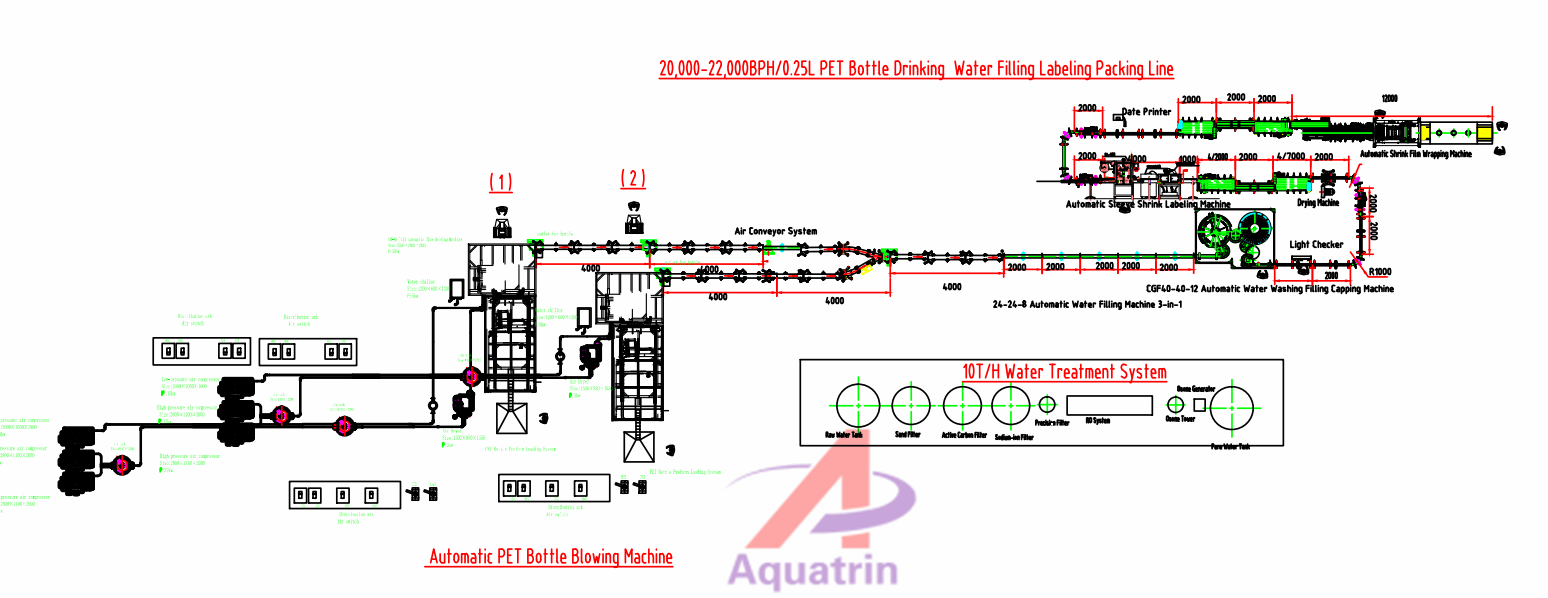

We suplly Free Factory Layout design

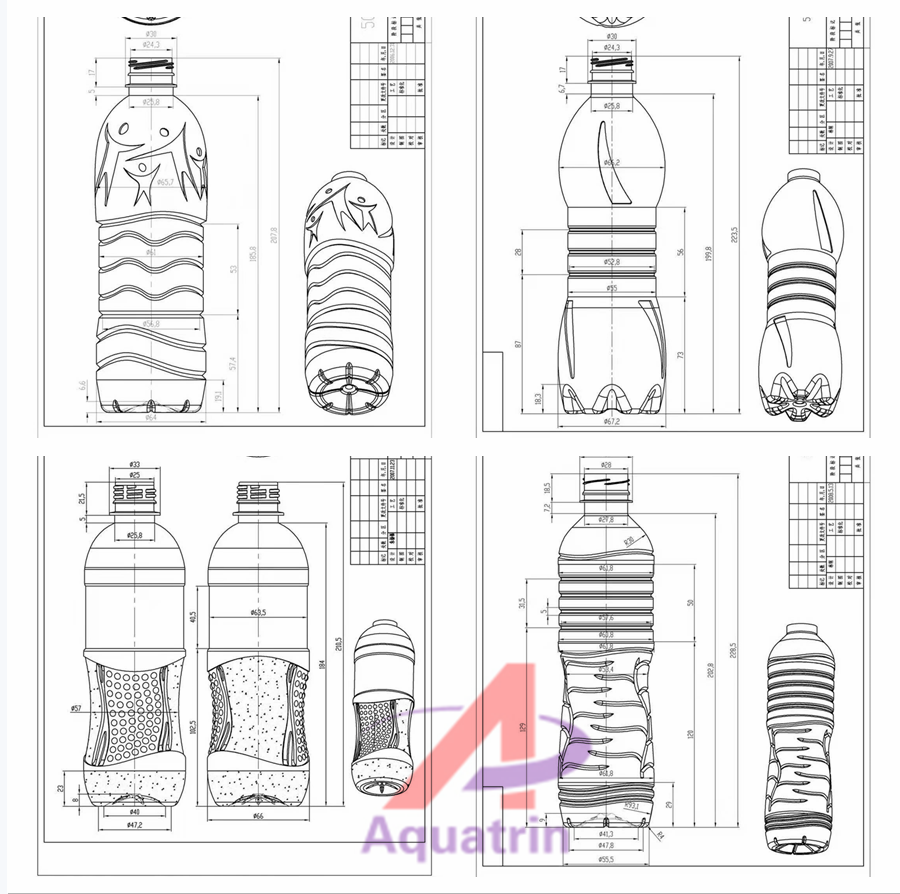

We suplly Free Bottle Shape design

Water treatment system

Labeling Machine

Laser date printer

PE film wrapping package machine

![]()