zhangjiagang aquatrin Machinery co.,ltd |

|

3-in-1 Filling Machine

This Automatic Wash-filling-capping Water Filling Machine is used to produce bottled mineral water, purified water, flavored water, alcoholic beverage and other non-gas Liquid. This Machine can be applied to all kinds of plastic products such as PET, PE. Bottles size varies from 250ml-2500ml meanwhile few changeover is needed. This series of filling machine capacity varies from 3000BPH to 32000BPH.

Our water filling machine is designed for the low/middle capacity and small factory. It features low water and low electricity consumption, small space occupation as well as easy operation. At the same time It improves the sanitary conditions and simplifies the maintenance compared with the last generation water filling machine. it can perfectly complete the function of automatic washing, filling and capping, which has been aproved by our clients as technical matured and quality product.

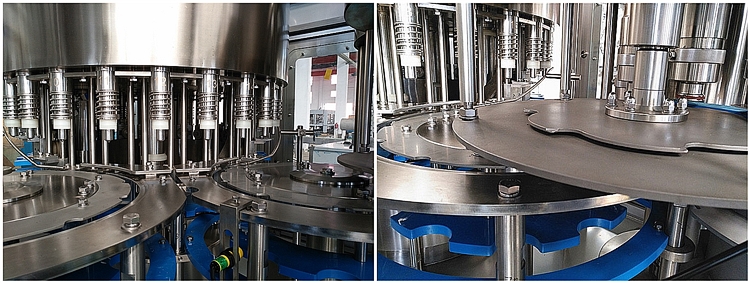

WASHING HEAD

Rotative rinsing turret one treatment, fixed nozzles, with grippers. It is suitable to the inner rinsing of PET bottles. The structure of the rinser is clad with AISI304 stainless steel. All parts in contact with the product are made of AISI stainless steel or food grade plastic material.

FILLING HEAD

This machine adopts high-speed large gravity flow valve filling valves, which is researched and developed by our Sophisticated R & D team, the adoption of this unique technology can greatly improve the filling speed and filling accuracy in the manufacturing process.

The valves that are internally polished are secured to the bowl and allow easy assembly and disassembly. The filling is by gravity light vacuum assisted. Each valve is composed of two pipes: the vent tube(connected to a manifold eventually kept under light vacuum) and the product pope (kept under atmospheric pressure)which received the product form the bowl. If the bottle is not present the valve does no deliver any product, when the required level has been obtained the filling stoops , the excess of product is sucked into the manifold, the bottle is lowered and the filling valve gets closed, the product sucked into the manifold can be fed back to the product bowl by means of a pump, or, in case of pasteurezed products, it is sent straightly to the pasteurizer.

CAPPING HEAD

Rotative capping turrent with heads, it is suitable to the application of screw plastic caps on PET bottles. The capper consists of a steel structure externally clad with a stainless steel AISI304 casing. The main element of this structure is rotating and is supported by a large diameter ball bearing. This rotating member of the capper is fitted with the capping heads, the relevant guides and the bottle holder plates. The fixed part consists of the cap hopper, the cap feeder with relevant motor and the cam actuating the capping heads. The hopper and all the parts in contact with the caps are made of stainless steel AISI304, polished finish. The feeder guides the caps onto a chultle fitted with a device to deliver them to the pick-off point with the open end down, the heads are raised an lowered by the action of a follower that is riding on a shaped cam.

The machine adopts hanging card bottle conveying structure, so that the whole line operation is more reliable. Different bottles only need to adjust the height of the empty bottle conveyor belt and a smallamount of accessories, and the height of the bottle conveyor belt does not need to be adjusted, so that the bottle shape change is more efficient and convenient. The spring type washing hand clamp, empty bottles with automatic track 180 degree flip, the inner part of the bottle washing, the washing nozzle adopts a quincuncial porous, so each angle of bottle bottom can be fully rinsed, improving washing efficiency.

Model | CGF8-8-3 | CGF14-12-5 | CGF16-16-6 | CGF24-24-6 | CGF32-32-8 | CGF40-40-10 |

Capacity | 2000PBH(500ML) | 5000PBH (500ML) | 8000PBH (500ML) | 12000PBH (500ML) | 15000PBH (500ML) | 18000PBH (500ML) |

Washing heads | 8 | 14 | 16 | 24 | 32 | 40 |

Filling heads | 8 | 12 | 16 | 24 | 32 | 40 |

Capping heads | 3 | 5 | 6 | 6 |

8 | 10 |

suitable bottle | PET bottle,plastic bottle | |||||

Diameter of bottle | 55-110mm | |||||

Height of bottle | 150-310mm | |||||

Suitable cap | Plastic screw cap | |||||

Weight | 1500kg | 2000kg | 4000kg | 4500kg | 6000kg | 7800kg |

Main motor power | 1.2kw | 1.5kw | 3kw | 3kw | 3kw | 5.5kw |

As usual, we adopt wooden case as package type. It's suitable for long-distance transport.According to customers' special demand, we could adopt sheet iron case and so on.

Generally, it will take 30 to 60 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.