Changzhou Jintan Lishen Macinery Co., Ltd |

|

100 Ton Automated Hydraulic Tablet Press Machine 5-7 Molds Per Minute Durable Automatic Blocking Making Machinery

| 1. Adopt the most advanced professional cartridge valve blocks, large flow path, save system pressure loss. Good seal performance, under long-term heavy load work condition , the system also won't appear insufficient phenomenon; Equipped with preliminary device, eliminate the hydraulic impact. |

| 2. Use two-way floating pressure adding system, ensure the uniform density of blocks, make sure the high density of blocks; The block hole part adopt core pulling cylinder, make the hole edge smoothly and good looking. |

| 3. Hydraulic cylinder are made of thick-wall seamless high strength alloy. In wall was honing by raw sandpaper and fine sandpaper by honing machine, ensure the cylinder in wall reach mirror surface, then make sure the good using performance. |

| 4. Adopt PLC automatic control system, strong anti-interference ability and low failure rat. Miniature relay adopt Japanese omron electric equipment, ensure the safety of control system. |

| 5. Adopt professional mould frame, use six guide pin to ensure accurate positioning, and equip mechanical position limitation, not only ensure the perfect outlook of pressed material also ensure the high quality. |

| 6. Adopt advanced fast device, small calorific value, high productivity, durable and energy saving (around 3/5 per minutes) |

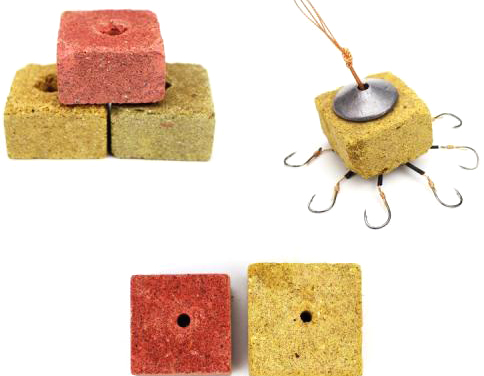

This machine can compress granular, powder-like material into a variety of general and special-shaped pieces. It is easy to learn mold replacement and installation. All actions record by the microcomputer PLC control, continuous automatic. We have not only a professional design institute and an experienced production team, but also complete and scientific quality control system. Our products can fully be in conformity with the national and industrial standards.

· We support Sample making and testing with your raw material.

· Every set of machine would be strictly inspected before shipment to ensure the quality.

· Test running with material could be supported according to your inquiry.

· There would be quality certificate along with machine.

· Easily Wear and tear parts would be shipped with machine.

· Real-time checking on line for machine manufacturing would be supplied if you like.

· Spot checking would be welcome if you like to visit our factory, and the whole journey would be arranged well for you.

Technical Parameters:

| Production Capacity | 4-6molds/min(the actual speed according to product process requirement) |

| Working Pressure | ≤100T(1. step-less adjustment 2. can be bidirectional compress) |

| Working Stroke | Up stroke≤250mm,down strokes≤150mm(1. step-less adjustment 2. Customized based on customer’s request. ) |

| Filling Depth | ≤150mm(1. step-less adjustment 2. Customized based on customer’s request. ) |

| Product Mould | Customized according to the tablet features(Multi-cavity Mould) |

| Apply to Shape | Round, square, or special-shaped(suitable for a variety of shapes) |

| Motor Power | 11kw 15kw(Servo) |

| Weight&Size | Approximately:3200kg 2500mm*1100mm*2300mm(L*W*H) |

Brief Introduction:

- Fully CNC Control Design: Each action can be set separately. Special material tablet forming can be solved by precise control and flexible technology.

- Fully Intelligent Operation Design: Production debugging is operated through PLC touch screen, which can cut the cumbersome process in great scope and make the operation more easily.

- Fully-automatic Material Filling Design: The filling method and dosage can be intelligently controlled,rapidly and stably, which can save much time and labor.

- Isolated Hydraulic Station Design: Oil cylinder working area and mechanical working area are Mutual independence, preventing oil pollution.

FAQ:

1. What about your tablet press machine quality?

Our factory has more than 10 years experience in mechanical processing; all our machines already get ISO9001 certificate; already exported into many countries and areas; already got customer’s good reputation.

2. How can you ensure the machine’s quality after we ordered?

Before the delivery, we will send you machine’s pictures and videos, or you can come to factory and check the tablet press machine by yourself, or by the third party inspection organization, contacted by your side.

3. What about your installation service and sales service for your tablet press machine?

1> Guarantee is one year, we will supply spare parts or send engineers to your side if you need, we will give you service anytime, 24 hours, 7days.

2> We already prepare technical manual and operation video to show our customers, then it will be easy to install and use the machine.

3> It is free to train your worker in our factory or in your side or by video.