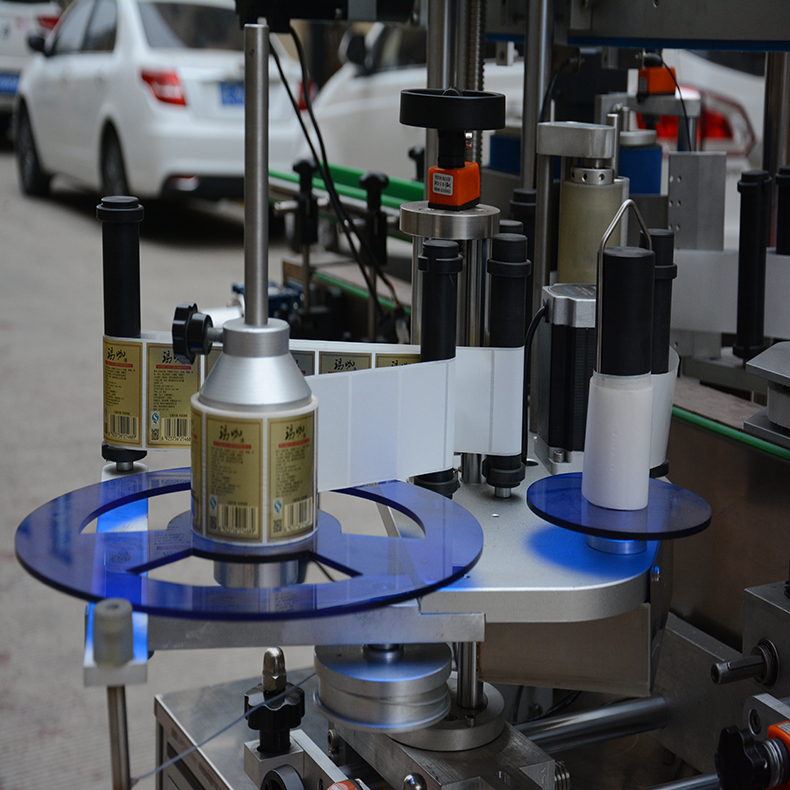

Automatic Front And Back Two Side Self Adhesive Sticker Labeling

Machine

OVERVIEW

Adaptable

The Front and back labeling machine accommodates a wide range of

labeling needs. Applying labels to the front and back of a

container is built into the two-side apply design. You can also

easily configure for a one-side apply or use the optional

wrap-station for round containers.

Simple to use

With the ability to easily make adjustments to the machine’s

settings, the Front and back labeling machine enables you to change

production runs quickly and simply – which means greater efficiency

and quality control.

Easy to upgrade

The Front and back labeling machine boasts a modular design that

allows you to upgrade its capabilities as your needs evolve.

Whether you have a custom product application or your product

changes, it’s simple to upgrade the machine to accommodate your new

requirements.

Made to Last

In strict compliance with Good Manufacturing Practices (GMP)

standards, the Front and back labeling machine is made of 304

stainless steel and anodized aluminum, and carefully treated to

guard against the effects of harsher environments. This durability

translates into a solid choice for labeling machine longevity.

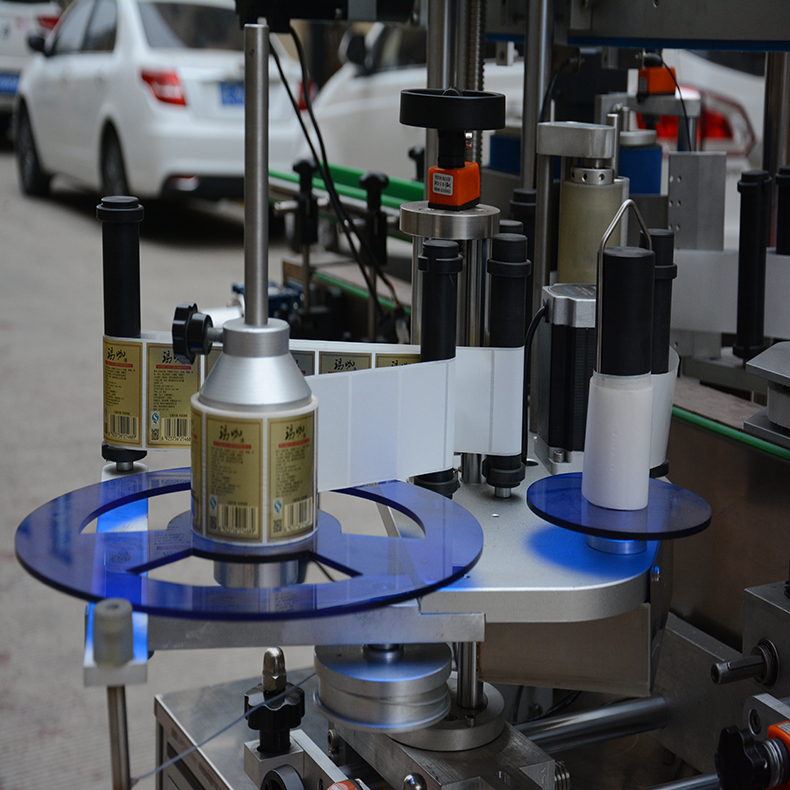

FEATURES

Flexibility

- With the Front and back labeling machine, labeling for a diverse

range of containers is fast and easy – regardless of size or shape.

The standard one-button teach product and label sensors make it

simple to adjust for various labeling applications. And, with the

manual position setting, your labels are placed accurately on the

product, each and every time.

- With label heads that tilt on a 12-degree x-y axis, the Front and

back labeling machine even works well for tapered or shaped

products.

- Future upgrades are simple. Thanks to the Front and back labeling

machine’s thermal or hot foil printer controls, you can easily

incorporate a printer if the need should arise. This integrated

feature lets printers work in sync with the labeler to ensure

accurate code placement. The result? Easy label customization you

can turn on or off.

Efficiency

- The auto label-set feature confirms label sensitivity by detecting

the separation between each label. With one push of a button,

labeling is automatically set up – and positioned correctly.

- The missing label-detect feature locates missing labels on the roll

stock, and instantly shuts the machine down if one is found. This

preventative feature ensures each product is labeled appropriately.

Accuracy

- Chain aligners center your product before entering top hold-down

controls that keep the product in place.

- The auto-length set feature ensures accuracy.

- The Front and back labeling machine’s controls are fully

synchronized, ensuring all components run at the same speed.

- With 360-degree touchscreen controls, the Front and back labeling

machine can be controlled from any position.

Productivity

- The production preset function means the machine automatically

stops once the predetermined quantity of products has been labeled.

- The label count feature lets you precisely track progress at any

point during the production run.

- The container/production run counter lets you see the exact

production number for the day.

- The Front and back labeling machine features a touchscreen control

system with job memory. So, even after the machine sits idle for

long periods, you benefit from a battery-free microprocessor

control system that stores default settings. Up to 30 settings can

be stored for future use, so you don’t have to waste time

re-entering the necessary information.

Practicality

- The Front and back labeling machine can be easily moved to other

production areas, allowing for changes in production or products.

- Maintenance is quick and simple, thanks to slide-out controls and

electronics stored in easy-to-access cabinets.

- All our labelers are made of 304 stainless steel and anodized

aluminum. This extremely durable metal is specially treated to

guard against rusting and other effects from harsher environments.

Compliance

- All our labelers are manufactured in compliance with Good

Manufacturing Practices (GMP) standards and meet the strict ISO

9001 quality control procedures. So, you can have confidence

undergoing required quarterly inspections from industry compliance

auditors.

Label Type

Speed

- Maximum Dispensing Speed : 131.2’/min (40m/min)

- Maximum Conveyor Speed : 131.2’/min (40m/min)

Dimensions

- Dimensions L-W-H : 112” x 72” x 56.3” (2845mm x 1829mm x 1429mm)

- Maximum Label Size : 7” x 12” (H 178mm x L 305mm)

- Maximum Container Width : 7.5” (191mm)

- Maximum Container Height : 13” (330mm)

- Conveyor Width : 6” (152mm)

- Conveyor Height : 33.5-35.5” (851-902mm)

- Spool Diameter : 14” (356mm)

- Inner Core : 3” (76mm)

Power

- Voltage : 110/220 VAC 50/60 HZ 1 Phase

- Power in KW : .1320

- Drive : Stepper Motor

- Net Weight : Approx 750 lbs (300 kgs)

- Controls : Delta Color Touch Screen