WANGDA Machinery Factory |

|

PE 600×900 All Steel Jaw Crusher Clay Red Block To Cut Hard Stone

Brick Crushing Machine

Product Introduction

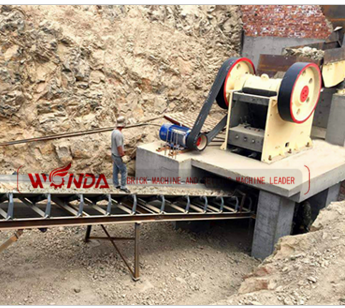

Primary Crushing is one of the most popular

stone crushing machines used in mining industry and it is ideally

suitable for both primary and secondary crushing. PE series single

toggle Primary Crushing has the features of great crushing ratio

and uniform sizes. Primary Crushing can be used to crush materials

with compressive resistance less than 320 MPA.

Primary Crushing is widely used in various

industries, such as mining, smelting, road and railway

construction, chemical industry, etc. Primary Crushing is used for

primary crushing and secondary crushing.The maximum compression

strength of materials to be crushed is 320MPA. Our design and

production are of high position both at home and abroad.

Working Principle

The motor transmits through belt,drives

the moving jaw to do periodic motion towards the fixed jaw by the

eccentric shaft.The angle between toggle plate and moving jaw plate

increases when mobile jaw moving.

So the mobile jaw moves towards the

fixed jaw.The stuff will be crushed in this process.The angle

between toggle plate and moving jaw decreases when moving jaw moves

down,the moving jaw moves leaves fixed jaw by pulling rod and

spring,the final crushed stuff will be discharged from the outlet.

Features

1. High-quality steel castings , driven by two large steel

flywheel. Forging stock processes heavy eccentric shaft resulting

superior reliability.

2. Bearing housings is overall steel structure, ensuring its

complete fit with the crusher frame and greatly enhancing its

radial strength.

3. Finite element analysis techniques,making the crusher a higher

strength.

4. Crusher cavity of symmetrical "V" -shaped structure, making the

actual inlet width consistent with the nominal inlet width.

5. Adjustment of the discharge port is more quick and convenient.

6. Larger, more durable eccentric shaft bearings and effective

labyrinth sealing make the bearings' life long.

7. Tooth plate, increased effective length of jaw board, higher

yields

Technology paramerters

| Type | Feeding Materials size(mm) | Discharging Granularity | | Rotate | Motor Power | Overall dimensions | Weight |

| PE400×600 | 350 | 40-90 | 16-60 | 260 | 30 | 1700×1732×1653 | 6800 |

| PE500×750 | 425 | 50-120 | 40-100 | 260 | 37 | 1930×2062×1853 | 12500 |

| PE600×900 | 480 | 80-180 | 60-200 | 250 | 55 | 2450×2200×2400 | 17600 |

| Type | Jaw Crusher |

| Application | Mining,Chemical Industry Motor |

| Power(W) | 37kw |

| Place of Origin | Henan, China (Mainland) |

| Dimension(L*W*H) | 1930x2062x1853mm |

| Certification | ISO 9001-2008 And CE |

| The Machines classification | Diesel Engine Mobile Crusher,Building Stone Production Line Spare parts supply |

| Max feeding size | 200-1020mm |

| Installation | Under Engineer's Guide |

| After sale Service | Life-long Service |

| Test&Installation | Senior |

| Professional Engineers Assigned Keyword | mining industry |

| Jaw crusher Name | Stone crushing machine jaw crusher |

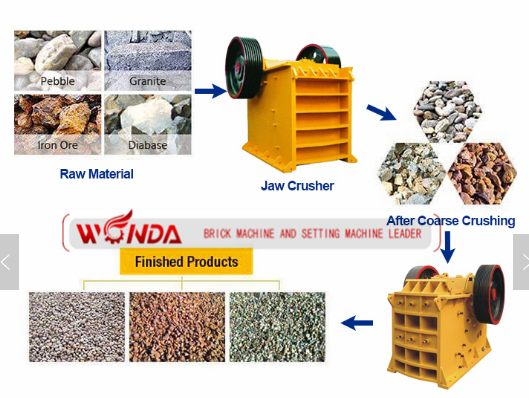

Raw Material

Terra Hollow Block Brick: Coal Gangue, and clay/soil/mud, fly ash, shale stone, stable

rock, rock, waste building material.

Tiles: silica, sand, feldspar.

Remark: The buyer should offer the representative material to make

the material testing report before the brick making processing line

design.

Fuel: coal or coal gangue mixed based on the Calorific value, biogas

used in kiln.

Our Services

1. Design most suitbale flow chart and layout freely according to

your request.

2. Provide operating instruction and relative drawing.

3. We can send 1-2 technicians to the site for guiding the

installation and commissioning.

4. We offer training service for free.

5. We offer the components with favorable price.

6. Lifetime Warranty.

FAQ

1. Q: Can I visit your factory?

A: Yes. Many domestic and overseas customers visited our factory

every year.

2. Q: What about the warranty of your equipment? Do you supply

spare parts?

A: Our warranty is 2 years(24 months), and we can supply spare

parts also.

3. Q: Do you provide after-sales service?

A: Yes. We have a professional after-sale service team to promptly

and thoroughly solve your problems.

4. Q: Do you provide equipment operation training?

A: Yes. We can send professional engineers to the working site for

equipment installation, adjustment, and operation training. All of

our engineers have passport.

5. Q: Do you provide producution flow chart?

A: Yes. Our experienced engineers are specialized in designing

process flow for stone crushing plant and various ores

beneficiation line.

6. Q: Can you test our sample raw material?

A: Yes. You can send your samples to us for testing and analysis.

7. Q: Have you made the whole stone crushing line?

A: Yes. We have made many large&small scale stone crushing line

at home and abroad.

Product Details

Our strength is remarkable