Shenzhen xinhuili Industrial Development Co., Ltd |

|

Company Profile

Founded in 2003, Jiangsu Winlong Pharmaceutical Machinery Co., Ltd. (stock code:836556), formerly known as Jiangsu Winlong Filling Machinery Co.( Ltd., is located in Jintan District, Changzhou City, Yangtze River Delta Economic Development Zone. Mainly engaged in providing overall solutions for smart workshops in pharmaceutical, biological, health product and daily chemical industries and manufacturing, selling, importing and exporting other packaging machinery products, it is a high-tech enterprise and a member unit of China Association for Pharmaceutical Equipment.

It is an important strategic objective of Winlong to participate in international competition and become stronger and more specialized. Our company attaches great importance to independent innovation, so that our product technology and quality stand at the forefront in the industry in China. With advanced technological innovation capacity and well-trained personnel, it provides domestic and foreign customers with overall individualized solutions for automatic production of many packaging production lines. In addition, it has also been granted a number of patents for invention. While actively responding to “Made in China 2025” and promote the industry 4.0 system engineering project, we are creating value for customers.

Overview

The series of products are mainly used for aseptic filling of serum, cell culture medium, etc. in such industries as medicine, biology, etc. The whole production process Is completed under the protection of 100-level laminar flow and aseptic isolation, ensuring aseptic production and conforming to the new version GMP requirements. The production line inherits internationally advanced technology in its structural principle, and incorporates various patented technologies with independent intellectual properly rights. It has reached the advanced level and can replace similar imported products.

Performance Features

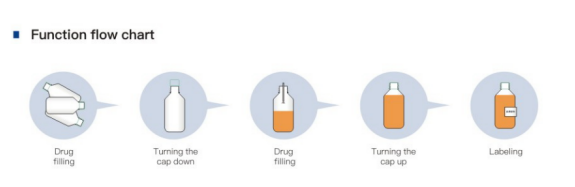

-Integrated structure of bottle unscrambling, cap taking, filling and cap turning, taking small floor space with stable and reliable operation.

-The peristaltic pump or ceramic pump is adopted, or for products of large vokjme, the weighing type filling principle is adopted, so as to ensure that the liquid is free from contamination.

-Safe and reliable 100-grade laminar flow protection system and ckust particles and airborne microbe detection system.

-The filling volume is adjusted on the man-machine interface with simple operation and high filling accuracy.

-Full servo-driven actions, stable, reliable and adjustable. PLC control system with variable frequency speed control, high degree of automation and high synchronization of all actions.

-The filling system is provided with the anti-leaking device, realizing filling from the bottom of the bottle, rising slowly and avoiding bubbles.

-The whote machine is suitable for various specifications of bottles and adjustments can be completed conveniently within a short time.

-The cap turning device is used for both cap taking and cap turning. The gripper type cap turning bead is adopted, which is stable and reliable with adjustable torque.

-The whole machine is designed according to GMP requirements.

-It is also suitable for the filling of capped bottles that have been sterilized in other fields.

Technical Parameters

| Product model: | XXQ2/1 | XXQ8/8 | XQD4/6 | XQD4/1 | XQD8/8 |

| Production capacity: | 15-20 bottles/minute | 50-60 bottles/minute | 80-120 bottles/minute | 15-20 bottles/minute | 10-20 bottles/minute |

| Number of filling heads: | 2 head | 8 head | 4 head | 4 head | 8 head |

| Filling range: | 1-30ml | 30-50ml | 500-1000ml | ||

| Filling accuracy: | ≤±0.5% | ||||

| Number of cap taking heads: | 1 head | 8 head | 6 head | 1 head | 8 head |

| Number of cap turning heads: | 1 head | 8 head | 6 head | 1 head | 8 head |

| Bottle moving mode: | Round disc positioning type | Linear positioning type | Continuous rotary type | Round disc positioning type | Linear positioning type |

| Pass rate: | ≥99.9% | ||||

| Power supply: | 220/380V 50/60Hz | ||||

| Power: | ≤2.2kw | ≤6kw | ≤6kw | ≤3kw | ≤6kw |

| Compressed air: | 0.4-0.6MPa | ||||

| Weight: | 800kg | 1500kg | 3000kg | 2000kg | 2000kg |

| Outline dimensions: | See the schematic dimension | ||||

![]()

![]()

About us

-Listed company founded in 2003(WINLONG GROUP CORPORATE)

-17 years’ manufacturing experience in the aseptic filling production line.

-Exclusive manufacturing factory of 20,000 square meters (Changzhou, Jiangsu)

-More than 100 famous enterprise business partners across China.

-Expanded global business network

-Proven design, efficient and reliabile products.

-Customized design to meet the customer’s demand.

Our Services and Warranty

1.We can customize the machine as customer required.

2.Available for OEM/ODM service.

3.Offer living broadcast or video support.

4.To Door installation and training service.

5.Offer filling line solution with customer requirement.

6.Customer’s design are welcomed.

7.Competitive price with on-time delivery.

8.Main spare parts one year warranty ( personal damaged except ).

We can customize with your packaging materials, production capacity and demands.

We will provide you with associated design solutions and case videos.