Zhangjiagang Jinyate Machinery Co., Ltd |

|

General description

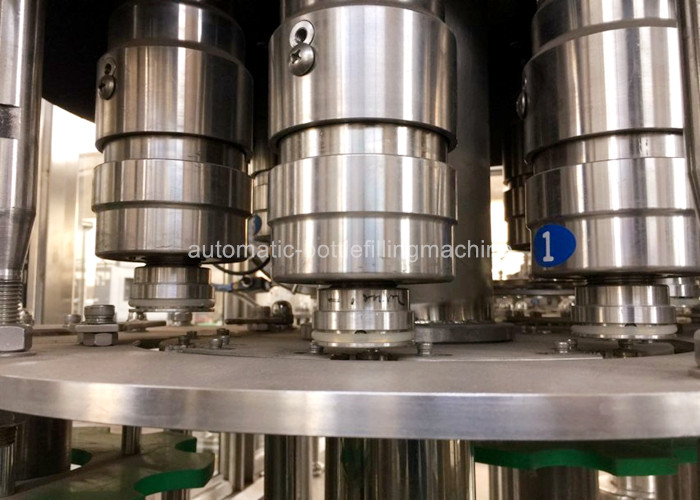

3-in-1 filling machine, combined with rinsing, filling and capping.

It is innovated and designed in the requirement of still pure water

and mineral water, on the bases of introducing, digesting and

absorbing advanced technology from Germany and Italy.

Technical parameters

| Model | CGF16-12-6 | CGF18-18-6 | CGF24-24-8 | CGF32-32-10 |

| Production capacity(500ml)(b/h) | 2000-4000 | 4000-6000 | 8000-10000 | 12000-15000(0.5L) |

| Filling precision | ≤±5MM(Liquid Level) | |||

| Polyester bottle standard(mm) | Bottle diameter40-80; | |||

| Height | Height:130-280 | (Height):150-320 | ||

| Suitable cap shape | Plastic Screw Cap | |||

| Water pressure of Washing bottle(MPa) | 0.18 | |||

| Water consumption for Water bottle (kg/h) | 800 | 1600 | 2500 | 3500 |

| Spraying position | 5 | 5 | 6 | 12 |

| Dripping bottle position | 3 | 3 | 3.5 | 7 |

| Gas source pressure(Mpa) | normal pressure | |||

| Gas consumption(m3/mm) | 0.3 | 0.3 | 0.4 | 0.5 |

| Total power | 4.23 | 5.03 | 6.57 | 8.63 |

| Total weight | 2000 | 3500 | 5500 | 8000 |

| Dimension(L*W*H)mm | 2100×1500×2200 | 2450×1800×2200 | 2750×2180×2200 | 3500×2200×2250 |

Main features

1. Rinser

2. Filler

3. Capper

If you are interested in our machine,don't hesitate to leave me message,Please kindly let me know :

1. How many bottles do you want to fill per hour?

2. What's your bottle size?