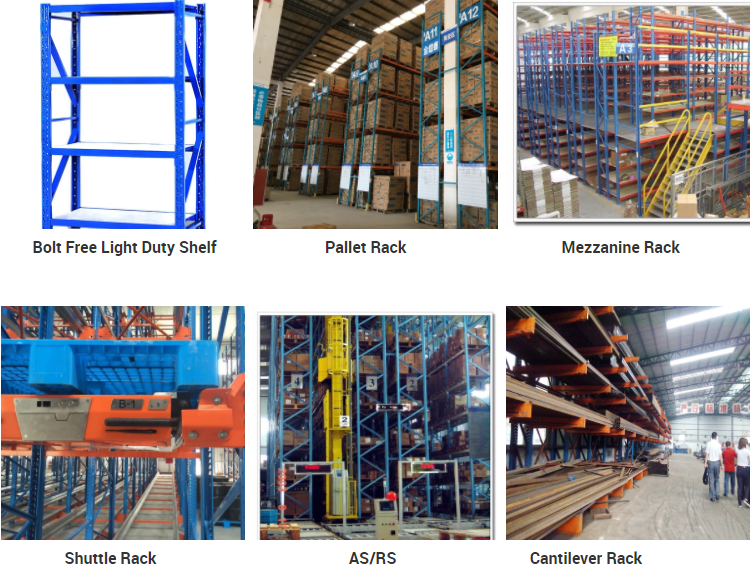

Logistic Inventory Automation System ASRS with Selective Storage

Racking

AS an important element of the modern logistics system, ASRS can

realize the high-level rationalization of the warehouse, the access

automation and the simple operation with the warehouse equipment.

ASRS is a high-level form of the current technology. The Automated

Warehouse is a multi-storey elevated warehouse system for storing

goods. It consists of shelves, stackers, conveyors, handling

equipment, pallets, management information systems and other

peripheral equipment. It is able to finish storage operations, and

the ability to manage inventory locations automatically makes it

plays a major role in modern enterprises. The Automated Warehouse

is widely used in the production and distribution of electronics,

machinery, medicine, cosmetics, tobacco, automobile and other

industries. It has the advantages of improving logistics management

level, improving operation efficiency, reducing cargo damage,

saving land occupation, saving manpower and material resources also

financial resources.

Specifications

AS/RS System refers to a variety of computer-controlled methods for

automatically placing.

| 1 | AS/RS System are usually equipped with pallet racking and drive-in

racking, both of which are composite structure. |

| 2 | Steel panels and wooden panels are available for loading with good

capacity. Conveyors will do the loading and unloading job under the

instruction from the central computer. |

| 3 | AS/RS System is mainly used in the food, tobacco, electronic,

mechanical and armament industry. |

AS RS warehouse rack mainly consists of following parts:

| Racking | Structural feature: AS/RS System are usually equipped with pallet

racking and drive-in racking, both of which are composite

structure. Steel panels and wooden panels are available for loading

with good capacity. Conveyors will do the loading and unloading job

under the instruction from the central computer. AS/RS System is

mainly used in the food, tobacco, electronic, mechanical and

armament industry. |

| Stacker | Structural feature: Double upright structure, steady and reliable,

vector frequency conversion drive and encoder position control,

mechanical and electronic safety devices to ensure safe using of

the system; All the way tracing technology by information

transferring; Electric components are imported from abroad;

Touching screen interface for easy operation; Making manual,

semiautomatic, automatic and linkage control come true; Used in

many situations by combining with other logistics equipment. |

| Conveying system | Structural feature: Conveying system is usually equipped in the

front or back of warehouse for conveying goods here and there,

bridging the procedures done by forklifts and stackers by using

rolling conveyor or chain conveyor and combining with lifts,

rotating devices and other equipments. |

| Controlling system | Structural feature: Communicating with WMS and ECS through OPC

agreement, PROFIBUS bus network, set up by Siemens S7-300

controller can operate all conveyors offline, doing conveying of

goods automatically.

Please refer to the attached drawing for details of conveying

system |

| WMS System | Hardwares of WMS System: Star network structure, network sever, RF

server, computers for management and monitor, RF base station and

RF terminal for in/out warehouse of goods. |

Advantage

| 1 | using the warehouse space fully |

| 2 | saving space reducing the H.R |

| 3 | removing mistake |

| 4 | improving working and management etc. |

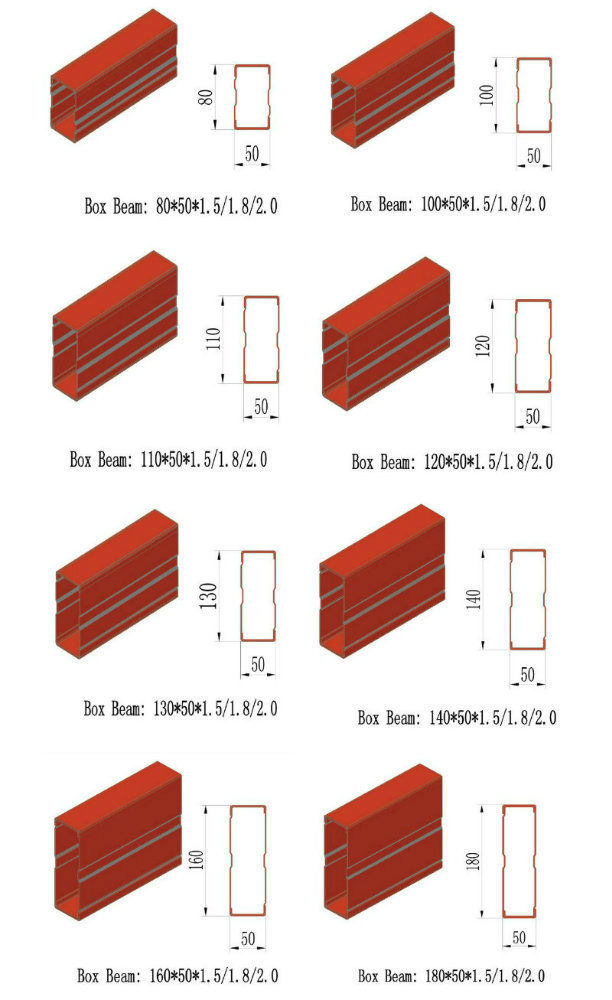

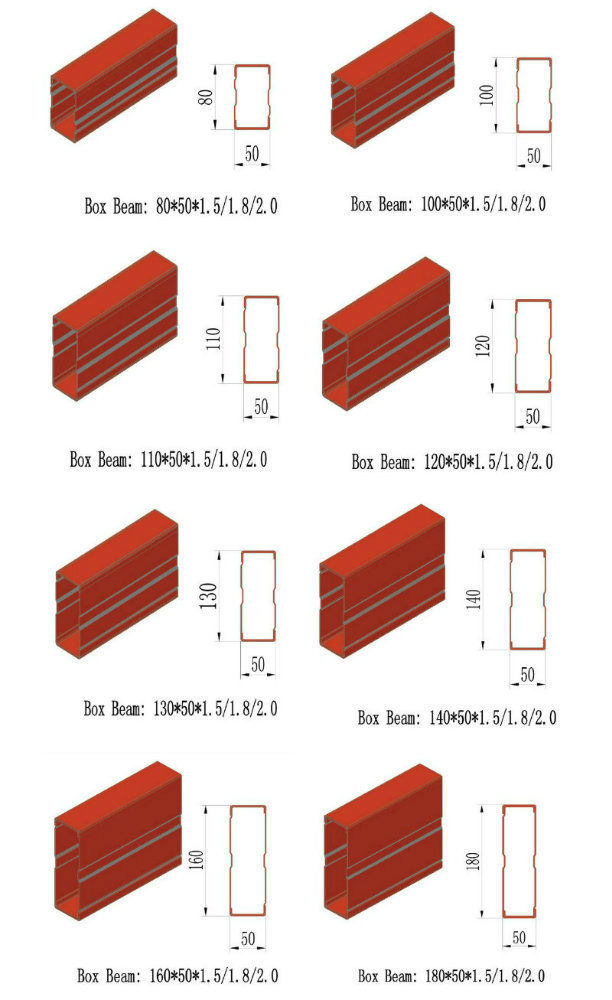

Beam

Please provide information for quick quotation

1. Pallet Size (Length*Width*Loading Height in mm)

2. Layout or Dimension (Length*Width*Net Height in mm) of your

warehouse

3. Rack Size (Length*Width*Depth in mm) if you are available or we

shall design for you

4. How many bays and levels if available

5. Loading Capacity(kg) of each level or each pallet

Production Of ASRS Rack

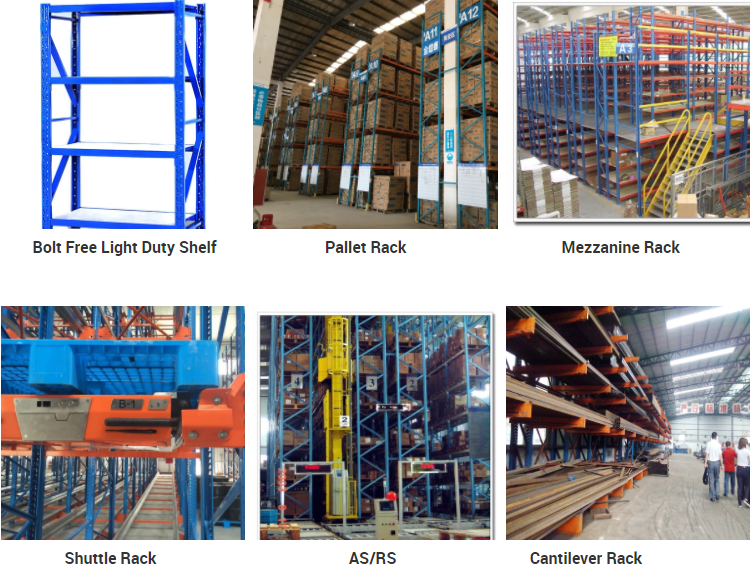

Main Products

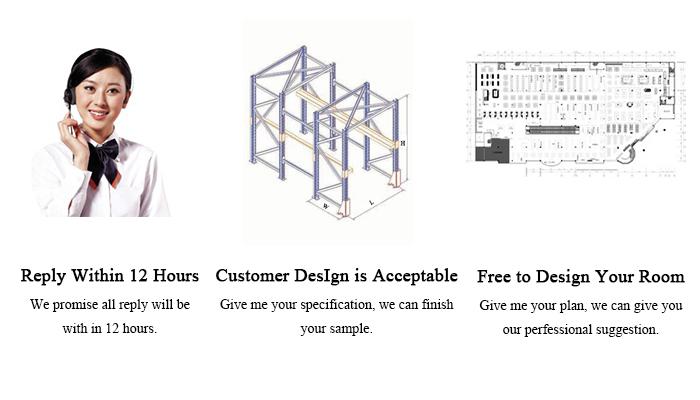

Why Choose HUICHEN?

1. 17 years experience on manufacturing warehouse racking;

2. All types of racking comply with ISO9001, CE etc;

3. Have successfully done thousands of racking project;

4. Factory direct sale price, no cost for middle distributor.

Really important to choose a reliable warehouse racking supplier!!!

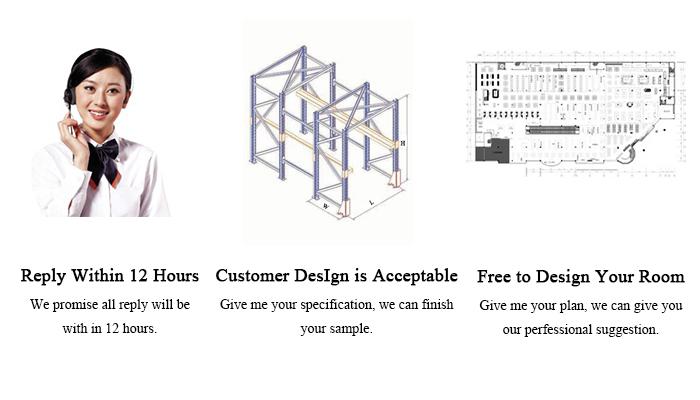

Service

Contact Us

Email: heidi@huichen.cn

Mobile: +86 176 6062 0398